- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser welding on metal

Results for

Laser welding on metal - Import export

VIRMER

Netherlands

Advantages of Laser welding: High welding speed (1-10 m/min). Welding without edges grooving. Minimal warp distortions. Minimal heat-affected zone. Applicable for welding of wide variety of materials. Welding process versatility. Possibility of automatization. Energy and wire saving. Comfortable labor conditions, working area maintained clean. Readme! Laser welding has a special property – it forms a high-density welding joint. Porosity and other defects that are inhere in other welding methods, are absent using this technology.

Request for a quote

VIRMER

Netherlands

Advantages of Laser welding: High welding speed (1-10 m/min). Welding without edges grooving. Minimal warp distortions. Minimal heat-affected zone. Applicable for welding of wide variety of materials. Welding process versatility. Possibility of automatization. Energy and wire saving. Comfortable labor conditions, working area maintained clean. Readme! Laser welding has a special property – it forms a high-density welding joint. Porosity and other defects that are inhere in other welding methods, are absent using this technology.

Request for a quote

THOMSON MACHINERY BV

Netherlands

with 6kW fiber laser and MP Flex loading and unloading for sale in top condition. C0z3xdk3ol

Request for a quote

VIRMER

Netherlands

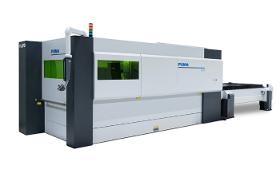

WATTSAN 1325 BASIC fiber laser machine is an economical and practical machine for cutting thin sheet metal. The metal cutting machine works with stainless and carbon steel, copper, aluminum, titanium and other materials. This machine is often purchased for manufacture, such as aviation, astronautics and mechanical engineering. We can install Maxphotonics / Raycus / IPG fiber laser emitter for choice. The main advantage of a fiber laser over a gas laser is its high speed and accuracy of operation, as well as durability: the life of the ignition unit is 100,000 hours, i.e. years of continuous operation. The machine has a working table 1300x2500 mm. WATTSAN 1325 BASIC laser machine is a high-precision device with a reliable control system. It has a high-quality fiber laser emitter. Of course, such a device will last a long time, because the declared service life of the frame is 20 years.

Request for a quote

VIRMER

Netherlands

Fiber metal cutting machine WATTSAN 1325 TABLECHANGE is a large and high-precision machine for cutting stainless and carbon steel, copper, aluminum, galvanized plates and other materials. On this machine, it is possible to install emitters of the following powers: 300/500/750/1000 Watts, and from 1500-5000 Watts with a protective cabin. One of the main advantages of all fiber lasers is durability: the life of the ignition unit reaches 100 000 hours. And this is about 10 years of continuous work. The manufacturer also claims that the bed of this machine can last 20 years. There are two options for the working field for this machine: 1300x2500 mm and 1500x3000 mm (1530 TABLECHANGE). For smaller workpieces, the 1300x2500 mm option is suitable; for industrial production, it is recommended to purchase a larger working area. If you have any doubts about the choice of the working field, please contact our specialists for advice.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VIRMER

Netherlands

WATTSAN 1530 ROTATORY CABINE is a powerful fiber laser machine, also known as a tube cutter. The device is equipped with a protective cabin for safe operation, as well as a rotary device. The rotary device takes the capabilities of your equipment to a whole new level. You can use the metal cutter like a regular cutter, and in a few minutes switch to the task of cutting tubes. The protective cabin is installed on machines from 1000 watts. This ensures the safety of the laser cutting operator, as well as minimizes the dangers of external influences. The machine is equipped with a fiber optic emitter: Max or Raycus or IPG. Such an emitter will last up to 100 000 hours of the most intensive work. If we talk about the intensity of work — the stand is weighted, crushes vibrations and will last 20 years, according to the manufacturer's information.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 TABLECHANGE is a high precision fiber laser cutting machine. It is equipped with an automatic change table. This design allows you to quickly change sheet metal while another workpiece is being cut. Such a system saves time and money for its owners. Such a machine has long been used in aircraft construction, mechanical engineering, light industry and medical equipment. The machine is equipped with a laser solid-state emitter to choose from: Max / Raycus / IPG. All three have proven themselves: Max is standard, Raycus is more expensive and better, and IPG is considered a premium series. All three types of emitters have a resource of about 100,000 hours. The automatic change table has a size of 1500×3000 mm for metal. The bed is made with a margin of safety, and the heavy weight dampens vibrations. Vibration mounts can be installed for added stability.

Request for a quote

COMPANY TOR

Russia

Operating from a single-phase 220 V network, the industrial welding inverter ТОРУС-250 Extra has an increased arc welding current up to 250 Amperes and, therefore, an increased percentage of operating time (TP). This allows performing continuous welding works: the device provides TP = 100% at an arc welding current of up to 225 Amperes (electrodes with a diameter of 5 – 6 mm). The power consumption when welding with “household” electrodes with a diameter of 3 mm is such that the device can be connected to a regular household outlet. Thus, the ТОРУС-250 Extra device is universal for industrial facilities and for cottage areas.

Request for a quote

COMPANY TOR

Russia

The VIKING-500 PRO semiautomatic welding machine has two-piece design, is designed for power supply from a three-phase 380V network and produces 500A at a load of 60%. The design feature consists in a separate feeding mechanism that can be removed from the source to a control cable length of up to 15 meters. The device heats up the product to a minimum, which allows you to work with thin metals. An important feature is the presence of a two-shaft motor for the wire inch (four rollers), which significantly improves the stability and smoothness of the welding material feeding. Special software functions significantly increase the performance factor of the device. ... Key features of VIKING MIG 500 PRO: - digital control of the device; - advanced software settings; - dot welding mode 2T and 4T; - setting of a smooth drop of the termination current; - adjustable inductance; - forced gas purging; - forced wire inch; - the presence of a 36 V socket (for connecting a CO2 gas heating regulator

Request for a quote

COMPANY TOR

Russia

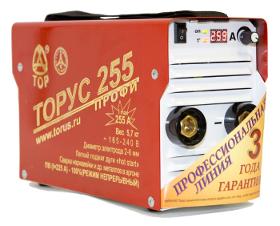

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quoteResults for

Laser welding on metal - Import exportNumber of results

11 ProductsCountries

Company type