- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- installation of pumps

Results for

Installation of pumps - Import export

ANCOTECH

Netherlands

Pressol pneumatic Oil pump installation set for 200/220L drum model 19235600 To pump Engine, transmission, hydraulic oil. Ideal for direct connection to pipeline systems up to 70 m Can be easily combined with several hose reels Suitable for oil up to SAE 90 Installation set consisting of: Oil pump 3:1 model 19235 Compressed air hose 2 m DN10 with quick couplings Euro profile Oil drain hose 2 m DN13 with 1/2G bi.bu Ball valve 1/2 Filter Pressure Regulator with Oil Mister 20218950

Request for a quote

POFI-ENGINEERING

Luxembourg

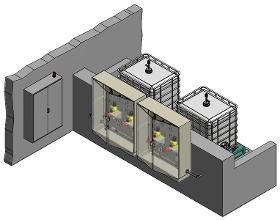

CONCEPT We found that on many production lines for flexible fac-ing panels, the three mixing heads did not produce the same quality of foam, even with the equivalent flow and pressure parameters. This is very often due to the poor distribution of the Polymix in the three high pressure pumps. After calculations and simulations of fluids, we have de-veloped a low pressure distribution unit to avoid dead zones and various preferential flows. Easy to install Better distribution on the 3 pumps Eliminates preferential flows Homogenizes the foam on the 3 heads . Do not hesitate to contact us for more information .

Request for a quote

ZBKIT LLC

Russia

One-plunger pumping units PT 1.1 with capacity up to 8 m3/h and pressure up to 40 MPa Three-plunger pump units according to API 674 (3-d edition) PT 1.3 and PT 2.3 with a capacity of 0.2 m3/h to 60 m3/h and pressure up to 80 MPa Five-plunger pumping units Pumping units are designed for pumping various liquids, including chemically active ones, with temperatures from -15 ° С to + 450 ° С, kinematic viscosity of not more than 8 cm / s, with the content of solid non-abrasive particles up to 0.2% by weight and size up to 0.2 mm.

Request for a quote

MPT DOSING GMBH

Germany

From left to right Dosing system for acid (left) and caustic (right). Sodium hydroxide-dosing system. Chemical-dosing systems are developed and manufactured for various applications and processes as complete, ready-for-connection function modules. Selecting the components and materials for constructing these systems requires long-year experience and comprehensive knowledge of the specific properties of the substances to be dosed. A lot of media are toxic and harmful to persons. Moreover, many are harmful to the environment and the groundwater. Substance properties such as a high viscosity or a high vapor pressure compromise the liability and a safe function if not considered when selecting and installing the pumps. For many years, MPT staff has been working in this specific area and gathered much experience when implementing hundreds of applications for nearly each topic in the range of premium dosing technology. From left to right Sulfuric acid-dosing station. Hardness

Request for a quote

NORTH RIDGE PUMPS LTD

United Kingdom

The SKM horizontal centrifugal multistage pump can be utilised for a wide range of applications in the industrial and marine markets. This multistage pump is designed to pump low viscosity clean or slightly contaminated fluids without the presence of solid or fibrous particles. This SKM pumps are capable of high pressures, up to 55 bar and high flow rates of up to 1000m³/hr and is also very robust due to additional bearings being installed in the pump head, these remove strain away from the motor during operation. Typical Applications & Industries: - Fresh Water and Sea Water - Fuels (Diesel, Petrol and Kerosene) - Boilers - Chemicals - Energy Plants - Mining - Industrial and Construction - and More

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Installation of pumps - Import exportNumber of results

5 ProductsCompany type