- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection moulding

Results for

Injection moulding - Import export

NORELEM FRANCE

France

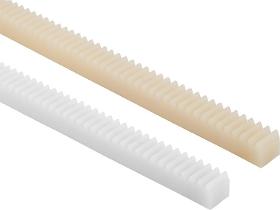

Injection moulded, straight teeth. Engagement angle 20°. Machined bore. Polyacetal, white. Polyketone, ivorytone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. The torques specified in the tables relate exclusively to the toothing.

Request for a quote

NORELEM FRANCE

France

Injection moulded, straight teeth. Engagement angle 20°. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Due to the material properties, plastic gear racks are not straightened. L= nominal length 250 mm. The actual length is roughly a whole multiple of the pitch.

Request for a quote

NORELEM FRANCE

France

Injection moulded, straight teeth. Engagement angle 20°. Axis angle = 90°. Machined bores from module 1.5. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. Bevel gear wheels are supplied as single components. To obtain a pair of bevel gear wheels, please order the specified mating gear as well.

Request for a quote

FATRA A.S.

Czech Rep.

Injection, injected products (from PP, LDPE, HDPE, etc. materials) – we offer the production on injection moulding machines with the clamp force of 420 – 800 t, moulded piece weight 80 – 3000 g. Our production assortment of injection-moulded products includes e.g. boxes, lids, tiles, protective plastic sides, or plastic containers. We offer the option of injection mould production including product development. Using your own moulds, any products according to specified parameters can be manufactured.

Request for a quote

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date injection molding machine design. For example the construction of clamp pistons tighten centrally and working even without lubrication. Our plastic molding machines have wide column intervals and we provide them with euromap standards. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our plastic injection machine. Same point precision stop is possible with our molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for injection mould changing. Our customer can have almost zero defects, scrap and failures with our plastic molding machines. Wit the help of our user friendly software, operator work pretty easy during plastic injection process.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 4,000 kN. Platen size 750 x 800 x 80 mm. Injection volume 2,000 cm³ or 5,000 cm³. The H610 allows Automated productions. Injection molding (more or less simple parts). A small footprint and height. An optimized cycle time. etc.

Request for a quote

REP INTERNATIONAL

France

Designed for the manufacture of highvoltage insulators (550 kV), this press is one of the largest presses made by REP. The dimensions of the parts to be injected explain the huge size of the press 660 mm in diameter, 2,600 mm long, moulded in one go. The production of a complete insulator is therefore performed in one or two cycles, thus significantly increasing the profitability and reliability of the parts. Machine features Closing force 24,000 kN Size of the platens 1,500 x 3,000 mm Injection volume 25,000 cm³ x 2 (2 injection units)

Request for a quote

REP INTERNATIONAL

France

Lean range G10 Core The G10 is the 10th generation of REP injection molding machines. With its ergonomic design and intelligent onboard solutions, the G10 generation is branded "Infinitely Smart". The G10 is available in two versions, G10 Core (Lean range) and G10 Extended (Performance range), designed to better meet the varied needs of customers. Lean range G10 Core Vertical rubber injection molding machines REP ideal for less demanding processes. The G10 Core range exists with three clamping forces 1,600 kN 3,050 kN 5,100 kN.

Request for a quote

REP INTERNATIONAL

France

Performance range G10 Extended Intelligent, elegant and efficient The G10 is the 10th generation of REP injection molding machines. With its ergonomic design and intelligent onboard solutions, the G10 generation is branded "Infinitely Smart". The G10 is available in two versions, G10 Core (Lean range) and G10 Extended (Performance range), designed to better meet the varied needs of customers. The G10 Extended is a line of presses adapted to the most demanding processes. The G10 Extended is progressively replacing the G9 generation machines and ranges from 1,600 kN (V410) to 10,200 kN (V910).

Request for a quote

REP INTERNATIONAL

France

Economic injection molding presses. A REP injection unit combined with a closing unit of a Tung Yu press. This combined technology offers openended options Separate extrusion and injection thanks to the "Y" type injection unit. 2 or 3stroke closing unit. Proportional closedloop temperature control. Optimized floor space and ergonomics thanks to its modular design.

Request for a quote

REP INTERNATIONAL

France

CFrame Injection molding machine V19. Optimized floor space and maximum accessibility. The V19 is an advanced Cframe press of 400 kN available in 2 versions, plastic or rubber injection. Its accessibility from three sides makes it ideal for the injection molding of profiles and extruded hoses.

Request for a quote

REP INTERNATIONAL

France

Type V410 Extended 1,600kN Machine features Clamping force 1,600 kN. Size of the platens 430 x 510 mm. Injection volume 1,000 cm³. Machine which is particularly used for the production of flat gaskets as used in fuel cell applications. This machine is available in our showroom « Area 111 » in Corbas (France) to perform your test runs for the injection molding of LSR parts.

Request for a quote

REP INTERNATIONAL

France

Type V510 Extended 3,050kN Machine features Clamping force 3,050 kN. Size of the platens 500 x 630 mm (630 x 630 mm optional). Injection volume 1,000 or 2,000 cm³. The G10 Extended range, performance for complex processes. Designed to better meet the various customer requirements with its embedded intelligent solutions.

Request for a quote

REP INTERNATIONAL

France

Type V710 Extended 5,100kN Machine features Clamping force 5,100 kN. Size of the platens 630 x 800 mm (800 x 800 mm optional). Injection volume 2,000; 5 000; 8,500 or 11,000 cm³. The G10 Extended range, performance for complex processes. Designed to better meet the various customer requirements with its embedded intelligent solutions.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 2,544 kN (station A) / 2 x 785 kN (station B & C). Size of the platens 630 x 500 mm. Injection volume 1,000 cm³; 2,000 cm³ or 5,000 cm³. The CMX (CompactMultiStation Generation X G10) is a 4station injection molding press 1 injection station (A), 2 curing stations (B and C), 1 demolding station (D). The CMX machine is available with two clamping forces 1,540 kN (CMX1) or 2,544 kN (CMX2).

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 1,540 kN (station A) / 2 x 502 kN (station B & C). Size of the platens 510 x 360 x 55 mm. Injection volume 1,000 cm³; 2,000 cm³ or 5,000 cm³. The CMX (CompactMultiStation Generation X G10) is a 4station injection molding press 1 injection station (A), 2 curing stations (B and C), 1 demolding station (D). The CMX machine is available with two clamping forces 1,540 kN (CMX1) or 2,544 kN (CMX2).

Request for a quote

REP INTERNATIONAL

France

Electric horizontal machine, ultra compact for an optimized productivity! Suitable for the injection of many elastomers (rubber, silicones, etc.) Compact & ergonomic 33% smaller footprint compared to other presses on the market All features and production capacity in less than 4 meters length Productive & electric powered performance Productivity +20% 60% reduction in injection time 30% decrease in cure time Sustainable & Ecofriendly 50% power consumption 100% Water consumption 14% Waste reduction Oil free The “SmartWire” technology allows production to become autonomous and connected.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REP INTERNATIONAL

France

The CMX (Compact Multi Station of the generation 10) This new machine replaces the former CMS generation and makes the third generation of rotary machines with 2 major innovations. Integration of the processcontrol system of the latest generation (generation 10) with all 4.0 functions. Product range with the CMX1 (160T clamping force) and the CMX2 (250T clamping force). New generation of 4station molding machines The REP solution for large productions with optimal efficiency 90% increase in productivity compared with a singlestation press. 68% increase in productivity compared with a press equipped with a double plate stripping kit. The CMX machine is available with two clamping forces 160T (CMX1) or 250T (CMX2).

Request for a quote

REP INTERNATIONAL

France

V410 LSR Machine features Clamping force 1,600 kN. Size of the platens 430 x 510 mm. Injection volume 1,000 cm³. Machine which is particularly used for the production of flat gaskets as used in fuel cell applications. This machine is available in our showroom « Area 111 » in Corbas (France) to perform your test runs for the injection molding of LSR parts.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 10,200 kN. Size of the platens 1,200 x 1,200 mm. Injection volume 5,000; 8,500 or 11,000 cm³. The G10 Extended range, performance for complex processes. Designed to better meet the various customer requirements with its embedded intelligent solutions. The G10 Extended range will progressively replace the G9 machines and extends from 1,600 kN (V410) to 10,200 kN (V910).

Request for a quote

REP INTERNATIONAL

France

URP Joint venture United Rubber Machinery Strategic Alliance for Asian injection molding machine market between REP and LWB Steinl,

Request for a quote

REP INTERNATIONAL

France

In short, large flat gasket REP machines mean Clamping quality Thick traverses, multiple synchronized clamping operations; Injection of long thin sections Injection pressure up to 3,000 bar and circuit division with several injection units; Productivity Very fast 3step clamping, doubleplate kits; Ergonomics/access to the mold Widthwise heating plates, demolding kit or sliding platen. These types of machines have been developed for largeseries injection molding involving parts with inserts, for example the injection molding of battery pack seals. Based on its longstanding experience in this field, REP offers a comprehensive range of machines with largesized heating plates and adjustable configurations to fully comply with the technical specifications of each application and all client’s needs.

Request for a quote

REP INTERNATIONAL

France

Machine features Closing force 3,200 kN. Size of the platens 1,250 x 630 mm. Injection volume 1,000 cm³. Machine developed for largeseries injection molding involving parts with inserts, such as for example the injection molding of housing seals.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 1,100 kN. Size of the platens 335 x 400 mm. Injection volume 400 or 1,000 cm³

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 500 kN. Size of the platens 300 x 300 mm. Injection volume 125 cm³.

Request for a quote

REP INTERNATIONAL

France

Machine features Clamping force 1,950 kN. Size of the platens 450 x 450 mm. Injection volume 1,000 cm³. The H49 is designed for Automated production. Injection molding (more or less simple parts). Low floor space and height requirement. An optimized cycle time. etc

Request for a quote

REP INTERNATIONAL

France

This press is intended for rubber overmolding of cables used for stone cutting. The cables must be positioned in the mould in the stretched position, and over moulding takes place successively in the jog mode. The “CFrame” design with a closing force of 1,000 kN has been tailored to these presses, because this technology gives access to all sides of the mold, what is essential for the successful finalization of this very special overmolding.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK manufactures sophisticated 1- and 2-component plastic parts with modern machinery. Our competences also include the corresponding mold and tool design.

Request for a quote

TECHNIC MACHINES

Turkey

We have the one of the most up-to-date pet preform injection molding machine design. Such as the construction of clamp pistons tighten centrally and working even without lubrication. Our pet preform molding machines have wide column intervals and we provide them with euromap standards on our pet preform injection machines. With the help of proportional controlled valve direction you can achieve fast opening-closing possible with our pet preform injection machine. Same point precision stop is possible with our pet preform molding machines. Also we have standard size holes and T slots according to Euromap standard on plates for pet preform injection mould changing.

Request for a quoteResults for

Injection moulding - Import exportNumber of results

65 ProductsCompany type