- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hdpe pp

Results for

Hdpe pp - Import export

TECHNIC MACHINES

Turkey

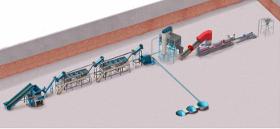

We design our plastic recycling machine to give best solution for waste plastic recycling process with minimum energy consumption. According to our customer's request, we offer different capacity options. Our plastic recycle machine is used mostly for plastic film and bag recycling process. It can work with raw materials such as PE, PP, PVC, HDPE, LDPE, Polythene, Polystyrene PET and etc. As tp market demand, we design our machine for working even with pretty dirty waste plastic film and bag. Also we offer our customers fully automatic or semi automatic solution. So, we provide for our customers, the plastic recycling machine according to their requirements. Plastic recycling line main units, – Bale Opening Unit – Shredder Unit – Helezons – Washing Systems – Separator Units – Screw Loading Units – Friction Washing Units – Dewatering Machinery – Agglomeration System – Granulating Machinery – Big Bag Filling Unit

Request for a quote

TECHNIC MACHINES

Turkey

We offer our Plastic Extruder Machine Lines for various industries, including construction, food, healthcare, white appliances, and automotive sectors. The most common raw materials used on our plastic extrusion machine lines include PVC, HDPE, PET, EPDM, PP, EPS, LDPE, PE, ABS, PC, PS, and others. We provide as standard Plastic Extruder Machine Lines WPC Extrusion Machine Strap Extrusion Machine Sheet Extruder Machine Rattan Extrusion Machine Polystyrene Extruder Machine Polycarbonate Extruder Machine Edge Band Extrusion Line Gasket Sealing Extrusion Machine As Technic Machines, we offer our customers optimal solutions for their specific needs in plastic extruder machine research. We provide custom solutions using twin screw extruders, single screw extruders, triplex extruders, or co-extruders. Our specialized extrusion line solutions are tailored to the final product requirements of our customers.

Request for a quote

FATRA A.S.

Czech Rep.

Plastic crate Plastic crate produced with injection moulding technology – primarily intended for use: In households. In food industry – for pastries, fruits and vegetables. Processed materials PP HDPE PP (polypropylene) is the second most frequently used material in Europe. Its share in consumption of plastic materials ranges about 20 %. Polypropylene is By its features and use, polypropylene is similar to polyethylene, therefore both of these polymers are classified in the same group indicated as polyolefins. Unlike PE, PP however features higher strength and consistency, and since its melting temperature is higher, it shows good temperature stability. PP consistency imparts good dimensional stability to products. Polypropylene can be found almost anywhere: in packaging materials, household appliances, clothing, means of transport, and many other products. More than half of the world PP production is used for packages. It is also used in technical applications. It is used...

Request for a quote

FATRA A.S.

Czech Rep.

Injection, injected products (from PP, LDPE, HDPE, etc. materials) – we offer the production on injection moulding machines with the clamp force of 420 – 800 t, moulded piece weight 80 – 3000 g. Our production assortment of injection-moulded products includes e.g. boxes, lids, tiles, protective plastic sides, or plastic containers. We offer the option of injection mould production including product development. Using your own moulds, any products according to specified parameters can be manufactured.

Request for a quote

MATCO

Belgium

Matco has a cooperation agreement for the Benelux and Germany with Hainaut Plast Industry, located in Cambrai (France). This company manufactures PVB out of windscreens and safety glass. Start: January 2016 Capacity: 15,000T/year post-consumer PVB with a 99.5% purity Type: pellets The pellets can also be grounded to powder (200µm) or be turned into liquid. The post-consumer PVB can be used as such (extrusion) or as a cost-reducing product to replace PP, PE, HDPE, PVC, PA, etc., it can be used in extrusion, thermo-forming and injection moulding. PVB applications: - Elastomers - Impact modifier - PVC compound - Textile binder - Hot melt - Coatings - Adhesives

Request for a quote

SOLOVIAN

Turkey

Most-traded Polymers: LDPE | Low-density polyethylene LLDPE | Linear Low-density polyethylene HDPE | High-density polyethylene PP | Polypropylene PVC | Polyvinyl Chloride PS | Polystyrene Nylon | Nylon 6 | Nylon 66 Teflon | Polytetrafluoroethylene TPU | Thermoplastic polyurethanes ABS | Acrylonitrile butadiene styrene ASA | Acrylonitrile Styrene Acrylate ETP | Engineering Thermoplastics Other plastics | Thermosets, adhesives, coatings and sealants PA | Polyamide PC | Polycarbonate PE | Polyethylene PE-MD | Polyethylene, medium density PET | Polyethylene terephthalate PMMA | Polymethyl methacrylate PS-E | Polystyrene, expandable PTFE | Polytetrafluoroethylene SAN | Styrene-acrylonitrile Plastics Materials | Thermoplastics + Polyurethanes (PUR) Thermo- Standard plastics (PE, PP, PVC, PS, EPS, PET (bottle grade) + Engineering plastics

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Hdpe pp - Import exportNumber of results

6 ProductsCountries

Company type