- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hardware

Results for

Hardware - Import export

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

revolving shaft material: free-cutting steel finish: plated with white zinc edge milled, side tapped with thread Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

HONSEL-GROUP

Germany

Electric-hydraulic setting tool for stationary automated or hand-held processing of blind rivet nuts and studs. Perfect combination of high setting force, slim design and low weight. The narrow design allows a small centre distance for modular design. — Process monitoring DMSD 2G Displacement encoder with resolution 0.01 mm Sensor technology force measurement via hydraulic pressure — Hydraulic connection for pressure intensifier — Mechanical connection — Tolerance compensation Position offset 1.5 mm Angular misalignment 8° — Electric motor Monitoring of torque and rotationangle during spindle mounting and dismounting — Hydraulic hollow piston cylinder stroke 12 mm setting force up to 58 kN — Quick-change system For fast handling and low-maintenance operation Low tool costs by using DIN screws as mandrel (option)

Request for a quote

HONSEL-GROUP

Germany

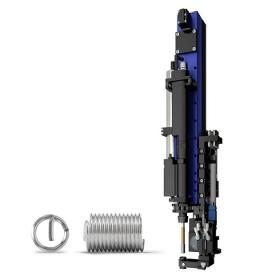

Coil screw system 2G for automated and partially automated installation of wire thread inserts. Due to the slim construction, screw systems can be placed close to each other. This leads to more efficient use of existing production areas and thus to greater economic efficiency in production. The electric linear motor is very fast at up to 3.2 m/s and enables cycle times in production to be optimized. — Screwdriver Bosch BG2 — Floating screwdriver bearings — Integrated coil transfer with rotary gripper — Linear motor — Camera

Request for a quote

HONSEL-GROUP

Germany

RivdomONE continues to impress. Indispensable for the work of many users today, the RivdomONE is equipped with many of the features of the HONSEL eBZ family, such as high-quality Li ion rechargeable batteries with RivdomPLUS charging technology, the flexible L-Boxx system and a powerful motor. The outstanding ergonomics and an extremely short trigger stroke allow quick and comfortable working. Familiar practical details such as the transparent mandrel collector, LED lighting of the riveting location or the new belt clip for mobile use round out the convincing impression of the new RivdomONE. Ergonomy and comfort: Quick-release mechanism - no more than one open-jaw wrench for maintenance! Extended warranty: We are convinced of the quality of our HONSEL battery riveters. That is why we grant a 24-month manufacturer's warranty on all current models.

Request for a quote

HONSEL-GROUP

Germany

The HONSEL Rivdom eBZ 3 battery riveter was developed specially for the demands of the setting of high-strength blind rivets with 6.4 and 7.8 mm diameter with grooved rivet stud! The clamping jaws specially designed for this geometry and a modified clamping mechanism guarantee reliable and positive settings of high-strength blind rivets with a stud diameter from 3.8 to 6.15 mm. This also helps to minimise wear on the clamping jaws. Rivdom eBZ 3 has a modern brushless DC (BLDC) motor. Ergonomy and comfort: Quick-release mechanism: No more than one open-jaw wrench for maintenance! Individual return mode setting: When using manual return mode, the trigger has to remain pressed until the rivet is sheared. When the trigger is released, the tool moves back to the front starting position. In addition Rivdom eBZ tools offer an automatic return mode. L-Boxx: Sturdy and flexible. High-quality RivdomPLUS battery system Extended 24-month manufacturer's warranty.

Request for a quote

HONSEL-GROUP

Germany

Small. Light. Smart. Industry 4.0 ready! With RivSmart you can now take the first step towards blind rivet processing of tomorrow – on the basis of decades of experience in the development of high-quality riveting tools and customised riveting automation technology. RivSmart can be easily integrated into our production processes, and with its documentation capabilities helps to optimise optimise and monitor production. Compact dimensions: Thanks to the removable transparent collecting bin, the tool can be further shortened for unrivalled ease of handling for even the most confined installation points. Weight only 1.3 kg. Documented process monitoring: RivSmart is equipped with the DMSD-lite process monitoring system. Serious errors can already be detected here and the number of set fasteners counted. Intelligent controller: In addition to its outstanding riveting properties, the RivSmart eBZ ZERO S is prepared for integration into an increasingly networked production environment.

Request for a quote

HONSEL-GROUP

Germany

Extremely lightweight. ultra compact. Optimised and specially designed for the world’s most widely used blind rivet sizes up to 4.0 mm diameter. In focus. Maximum weight reduction and compact dimensions. The outstanding ergonomics and unrivalled light weight of only 1.3 kg guarantee the highest level of comfort! — Rivdom eBZ ZERO has a modern brushless DC (BLDC) motor. Ergonomy and comfort: Quick-release mechanism: No more than one open-jaw wrench for maintenance! Individual return mode setting: When using manual return mode, the trigger has to remain pressed until the rivet is sheared. When the trigger is released, the tool moves back to the front starting position. In addition Rivdom eBZ tools offer an automatic return mode. L-Boxx: Sturdy and flexible. High-quality RivdomPLUS battery system Extended 24-month manufacturer's warranty.

Request for a quote

HONSEL-GROUP

Germany

The power pack. For blind rivets up to 6.4 mm. The setting force of 20,000 N and the very large stroke of 30 mm enables not only standard blind rivets but also high-strength versions such as HONSEL FERO® Bulb and FERO® Bolt (or comparable products) and folding blind rivets up to 6.4 mm diameter to be quickly and reliably set in one step. Uncompromisingly powerful. Rivdom eBZ 2 has a modern brushless DC (BLDC) motor. Ergonomy and comfort: Quick-release mechanism: No more than one open-jaw wrench for maintenance! Individual return mode setting When using manual return mode, the trigger has to remain pressed until the rivet is sheared. When the trigger is released, the tool moves back to the front starting position. In addition Rivdom eBZ tools offer an automatic return mode. L-Boxx: Sturdy and flexible. High-quality RivdomPLUS battery system Extended 24-month manufacturer's warranty.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing: 2008 CNC control: FANUC 21i-T Centre distance: 1000 mm Height of centers: 175 mm Max. grinding diameter: 349 mm Max. grinding length: 1000 mm Stroke X axis: 350 mm Max. Stroke speed X axis: 6000 mm/min Resolution X axis: 0.0001 mm Stroke Z axis: 1150 mm Max. Stroke speed Z axis: 12000 mm/min Resolution Z axis: 0.0001 mm Orientation of table: 0 - 9 ° Grinding wheel min. speed: 800 rpm Grinding wheel max. speed: 1900 rpm Grinding spindle motor power: 6 kW B axis swiveling stroke: -210 / +10 ° B axis indexing precision: 1 ° Automatic B axis: Yes Max. diameter grinding wheel: 400 mm Workpiece spindle nose: DIN 55026 N° 5 Internal workpiece spindle nose: Morse 5 Workpiece spindle min. speed: 8 rpm Workpiece spindle max. speed: 800 rpm Max. part weight in part holder headstock between centers: 100 Kg Workpiece swiveling range: -10 / +100 ° + EQUIPMENT INCLUDED

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing :2016 CNC control: FANUC 31i Software installed: Quinto 5.4.6 Number of axes: 5 Stroke X axis: 470 [mm] Max. Stroke speed X axis: 20000 [mm/min] Stroke Y axis: 390 [mm] Max. Stroke speed Y axis: 20000 [mm/min] Stroke Z axis: 325 [mm] Max. Stroke speed Z axis: 10000 [mm/min] Table length: 1000 [mm] Table width: 275 [mm] Grinding wheel speed: 12000 [rpm] Grinding spindle motor power: 10 [kW] Internal workpiece spindle nose: HSK 50 Dimension:s 2600 x 3500 x 2600 [mm] Weight: 4700 [Kg] Machine visible under power in our premises by appointment. Price on request, loading on truck included. Possibility of shipping Worldwide.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Pallet loading automation unit 4 stations 1 pallet included Technical documentation included

Request for a quote

KRAFFTER MACHINE TOOLS

France

x1 infeed Z-axis: Infeed operation, metric 4 E-M with position reading - ref: 111-2-10666 x1 cross feed X-axis Fine cross feed 4 FQ-M - ref: 111-2-21708 x1 grinding stroke 3H: operation of the grinding stroke either by lever or by hand wheel - ref: 111-2-15167 (WS11) x1 grinding spindle Q 36-12, complete 9 JKP x1 workhead spindle BP 60-25 with W25 collet reception x1 dust extraction unit x1 foot switch 9 M - operation of infeed Z-axis by foot pedal. Infeed stroke sleeplessly adjustable - ref: 111-2-15740 x1 LED machine lamp 24V/2.6W x1 digital display 4DZ + X +Y-MZ + digital indications for axes Z, X and Y - ref: 111-2-47178 x1 ISOMA microscope - optic from the front x1 ISOMA microscope - optic from the top x1 radius grinding attachment 25ABP - ref: 111-2-23294 x1 dividing head TS20 (6°) for radius grinding attachment 20ABP/25ABP - ref: 111-2-42192 x1 Touch-Test TT acoustic touch control (grinding wheel to workpiece) - ref: 56-4050 x1 Headset TT-K Stereo - ref: 56-4755

Request for a quote

KRAFFTER MACHINE TOOLS

France

Stroke X axis: 650 mm Max. Stroke speed X axis: 4000 mm/min Working feed X axis: 0 - 1800 mm/min Stroke Y axis: 450 mm Working feed Y axis: 0 - 1800 mm/min Stroke Z axis: 130 mm Min. Stroke speed Z axis: 0.5 mm/min Max. Stroke speed Z axis: 12000 mm/min Stroke frequency Z axis: max. 4 Hz Stroke W axis: 500 mm Planetary speed C axis: 5 - 250 rpm Max. Stroke speed W axis: 800 mm/min Stroke U axis (radial feed): 5.5 mm Distance between columns: 750 mm Table length: 770 mm Table width: 630 mm Clearance between grinding motor and table: 585 mm Max. load on table: 500 Kg Supply voltage: 400 V Weight: 4550 Kg EQUIPMENT INCLUDED: x1 HI-CUT pack including: -work area protection -exhaust system with electrostatic air filter -fire protection system (to be assessed by a qualified body) -automatic paper tape filtration unit x1 grinding motor x1 cable for grinding motor Machine visible under power in our premises by appointment.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing: 1998 Number of axes: 2 Stroke X axis: 180 mm Stroke Z axis: 600 mm Rapid traverse rate Z axis: 4000 mm/min Distance between centres: 600 mm Height of centers: 150 mm Max. swing over bed: 340 mm Height of centers over cariage: 177 mm Spindle nose: CAMLOCK D 1-4’’ Internal spindle nose: CM5 Spindle for collets: B32 Spindle throughbore: 40 mm Min. spindle speed: 55 rpm Max. spindle speed: 3000 rpm Spindle power: 4 kW Type of attachment tailstock: CM5 Metric pitches: 0.25 - 14 mm Imperial T.P.I.: 112 - 1/2" filets/pouce Module pitches: 0.12 - 7.5 modules Lubrication tank capacity: 29 l Total power required: 6 kVA Supply voltage: 400 V Dimensions: 1730 x 970 x 1300 mm Weight: 1250 Kg + EQUIPMENT INCLUDED

Request for a quote

KRAFFTER MACHINE TOOLS

France

CNC control: FANUC 31i Number of axes: 7 Stroke Y axis: -/+ 40 mm Stroke Z1 axis: 340 mm Stroke X1 axis: 180 mm Stroke Z2 axis: 440 mm Stroke X2 axis: 195 mm Rapid traverse rate X axis: 30000 mm/min Rapid traverse rate Z axis: 30000 mm/min Rapid traverse rate Y axis: 10000 mm/min Spindle nose: DIN 55026 A size 4 Spindle through bore: 42 mm Max. spindle speed: 8000 rpm Spindle power: 7 kW Counter spindle nose: DIN 55026 A size 4 Counter spindle through bore: 26 mm Max. counter spindle speed: 8000 rpm Counter spindle power: 3.8 kW Type of tool holders: VDI 25 Turret indexing time: 0.4 s/pos Turret 1: SAUTER Number of tool stations - Turret 1: 12 Number of tool stations driven - Turret 1: 12 Max. speed driven tools - Turret 1: 6000 rpm Turret 2: SAUTER Number of tool stations - Turret 2: 12 Number of tool stations driven - Turret 2 12 Max. speed driven tools - Turret 2: 6000 rpm + EQUIPMENT INCLUDED

Request for a quote

KRAFFTER MACHINE TOOLS

France

CNC control: FANUC 31i - MODEL A Distance between chucks: 639 mm Max. turning diameter: 255 mm Height of centres over carriage: 270 mm Stroke Z1 axis: 500 mm Stroke X1 axis: 190 mm Stroke Y1 axis +/-: 40 mm Stroke Z2 axis: 500 mm Stroke X2 axis: 190 mm Stroke Y2 axis +/-: 40 mm Rapid traverse rate X axis: 16000 mm/min Rapid traverse rate Z axis: 20000 mm/min Rapid traverse rate Y axis: 12000 mm/min Axes acceleration: 1g Spindle nose: ASA 8" A2 Max. bar diameter: 66 mm Spindle through bore: 77 mm Max. spindle speed: 4000 rpm Spindle power: 15 kW Spindle torque: 136 Nm Counter spindle nose: ASA 6" A2 Max. bar diameter counter spindle: 52 mm Counter spindle through bore: 61 mm Counter spindle stroke: 635 mm Max. counter spindle speed: 5000 rpm Counter spindle power: 7.5 kW Counter spindle torque: 68 Nm Turret indexing time: 0.1 s/pos + EQUIPMENT INCLUDED

Request for a quote

KRAFFTER MACHINE TOOLS

France

CNC control: Fanuc 0i-TB Number of axes: 7 Max. cutting diameter: 42 mm Max. turning length: 100 mm Stroke Z1 axis: 246 mm Stroke X1 axis: 165 mm Stroke Y1 axis: +/- 40 mm Stroke Z2 axis: 525 mm Stroke X2 axis: 70 mm Rapid traverse rate X axis: 18000 mm/min Rapid traverse rate Z axis: 20000 mm/min Rapid traverse rate Y axis: 12000 mm/min Spindle through bore: 43 mm Min. spindle speed: 60 rpm Max. spindle speed: 6000 rpm Increment C-axis: 0.02 ° Spindle power: 11 kW Counter spindle through bore: 36 mm Min. counter spindle spindle speed: 67 rpm Max. counter spindle speed: 7000 rpm Counter spindle increment C-axis: 0.02 ° Counter spindle power: 5.5 kW Max. tool holder cross-section: 20 mm Number of tool stations driven - Turret 1: 12 Max. speed driven tools - Turret 1: 4000 rpm Indexing time - Turret 1: 0.25 s/post Number of tool stations - Turret 2: 6 Indexing time - Turret: 0.20 s/post Live tools power: 2.5 kW + EQUIPMENT INCLUDED Machine visible under power

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Steel Turned Parts Mechanical Assemblies Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

ITM COMPONENTS

United Kingdom

These cables are manufactured per the mechanical requirements of the USB3 Vision standard. In addition to supporting the machine vision camera market, the screw mount hardware is beneficial in many applications where standard USB connectors can become dislodged due to jostling, vibration, etc. USB 3.0 cables are up to 10 times faster than USB 2.0 - 4.8 Gbps versus 480 Mbps. The increased bandwidth substantially reduces the time required for transferring large amounts of data or video. L-com is a member of the AIA (Automated Imaging Association) trade group. Applications: Machine vision camera market Data Storage Data Acquisition Video Transfer USB3 Vision Applications

Request for a quote

LIQUID-UNIVERSUM GMBH

Germany

we are first distributor in europe for CCELL Vape Hardware, which is specially developed for cbd/thc vaping

Request for a quote

LIQUID-UNIVERSUM GMBH

Germany

we are first distributor in europe for CCELL Vape Hardware, which is specially developed for cbd/thc vaping

Request for a quote

LIQUID-UNIVERSUM GMBH

Germany

50% vape products in ccell or other hardware, vape catridges 510 or special

Request for a quoteResults for

Hardware - Import exportNumber of results

48 ProductsCountries

Company type