- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding

Results for

Grinding - Import export

SPARX MACHINE TOOLS

United Kingdom

The Kuhlmeyer ZBS Twin Belt Grinding Machine is built for the roughing and finishing on welded edges, corners and surfaces on flat and mid-size workpieces out of steel, stainless steel, and aluminium, i.e. doors, frames, cabinets, housings, hoods, furniture parts, frame parts in automotive and aircraft – manufacturing, round bins, cylinders, heaters etc.

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

Cutting, deburring and grinding operations, which are generally carried out with manual operations, are problematic in standardization and very risky in terms of HSSE. With robotic projects, we obtain the most precise results in a safe way.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Jung JF520 surface and profile grinding machine in very good condition. Machine No. 1569. Year of construction 1981 - Grinding length max. 600 mm - Sliding width: 200mm - Magnet size: 500x175mm - Grinding wheel dimensions: 250x25x50.8mm Bcspaqsayd8 - Spindle speed: stepless 4200 omw./min. - 380V 4kW - Weight about 2000kg Equipment: - 1 axis digital display, - Flanges - Infinitely adjustable spindle speed - Infinitely variable hydraulic supply in transverse direction - auto lubrication system, - Automatic height feed with rapid traverse - machine books

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 2002 CNC control : FANUC 160i-M Stroke X axis : 1300 mm Max. Stroke speed X axis : 1800 mm/min Rapid traverse rate X axis : 4000 mm/min Stroke Y axis : 800 mm Max. Stroke speed Y axis : 1800 mm/min Rapid traverse rate Y axis : 4000 mm/min Stroke Z axis : 170 mm Min. Stroke speed Z axis : 0.500 mm/min Max. Stroke speed Z axis : 14000 mm/min Stroke frequency Z axis : max. 5 Hz Stroke W axis : 635 mm Rapid traverse rate W axis : 1150 mm/min Planetary speed C axis : 5 - 300 rpm Stroke U axis (radial feed) : 5.5 mm Distance between columns : 970 mm Table length : 1440 mm Table width : 860 mm Max. distance spindle nose / table : 750 mm Max. load on table : 800 Kg With equipment

Request for a quote

APD MAQMASTER

Spain

Cutting machine for PVC beading, with 45º angled cut The beading machine includes a digital and automatic roller path

Request for a quote

KRAFFTER MACHINE TOOLS

France

x1 infeed Z-axis: Infeed operation, metric 4 E-M with position reading - ref: 111-2-10666 x1 cross feed X-axis Fine cross feed 4 FQ-M - ref: 111-2-21708 x1 grinding stroke 3H: operation of the grinding stroke either by lever or by hand wheel - ref: 111-2-15167 (WS11) x1 grinding spindle Q 36-12, complete 9 JKP x1 workhead spindle BP 60-25 with W25 collet reception x1 dust extraction unit x1 foot switch 9 M - operation of infeed Z-axis by foot pedal. Infeed stroke sleeplessly adjustable - ref: 111-2-15740 x1 LED machine lamp 24V/2.6W x1 digital display 4DZ + X +Y-MZ + digital indications for axes Z, X and Y - ref: 111-2-47178 x1 ISOMA microscope - optic from the front x1 ISOMA microscope - optic from the top x1 radius grinding attachment 25ABP - ref: 111-2-23294 x1 dividing head TS20 (6°) for radius grinding attachment 20ABP/25ABP - ref: 111-2-42192 x1 Touch-Test TT acoustic touch control (grinding wheel to workpiece) - ref: 56-4050 x1 Headset TT-K Stereo - ref: 56-4755

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing :2004 CNC control: FANUC 180i-MB Stroke X axis: 500 [mm] Min. Stroke speed X axis: 0.0001 [mm/min] Max. Stroke speed X axis: 2000 [mm/min] Stroke Y axis: 300 [mm] Min. Stroke speed Y axis: 0.0001 [mm/min] Max. Stroke speed Y axis: 2000 [mm/min] Stroke Z axis: 140 [mm] Min. Stroke speed Z axis: 0.0001 [mm/min] Max. Stroke speed Z axis: 2000 [mm/min] Stroke W axis: 350 [mm] Planetary speed C axis: 1 - 300 [rpm] C axis max. speed: 20 [rpm] Max. Stroke speed W axis: 2000 [mm/min] Stroke U axis (radial feed): 11 [mm] Table length: 610 [mm] Table width: 305 [mm] Supply voltage: 400 [V] ADDITIONAL INFORMATION: x1 spindle DÄNZER DHB 0911.000 WW x1 oil cooler TURMOIL model OCO-33 RO x1 mist extraction unit FILTERMIST model F600 x1 MOORE Autosize tool edge probe x1 MOORE TOOL automatic wheel dresser x16 tool holders x1 RENISHAW OMP 40 workpiece probe x1 MOORE TOOL clamping box Full technical documentation

Request for a quote

KRAFFTER MACHINE TOOLS

France

TECHNICAL CHARACTERISTICS : Year of manufacturing :2016 CNC control: FANUC 31i Software installed: Quinto 5.4.6 Number of axes: 5 Stroke X axis: 470 [mm] Max. Stroke speed X axis: 20000 [mm/min] Stroke Y axis: 390 [mm] Max. Stroke speed Y axis: 20000 [mm/min] Stroke Z axis: 325 [mm] Max. Stroke speed Z axis: 10000 [mm/min] Table length: 1000 [mm] Table width: 275 [mm] Grinding wheel speed: 12000 [rpm] Grinding spindle motor power: 10 [kW] Internal workpiece spindle nose: HSK 50 Dimension:s 2600 x 3500 x 2600 [mm] Weight: 4700 [Kg] Machine visible under power in our premises by appointment. Price on request, loading on truck included. Possibility of shipping Worldwide.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Stroke X axis: 650 mm Max. Stroke speed X axis: 4000 mm/min Working feed X axis: 0 - 1800 mm/min Stroke Y axis: 450 mm Working feed Y axis: 0 - 1800 mm/min Stroke Z axis: 130 mm Min. Stroke speed Z axis: 0.5 mm/min Max. Stroke speed Z axis: 12000 mm/min Stroke frequency Z axis: max. 4 Hz Stroke W axis: 500 mm Planetary speed C axis: 5 - 250 rpm Max. Stroke speed W axis: 800 mm/min Stroke U axis (radial feed): 5.5 mm Distance between columns: 750 mm Table length: 770 mm Table width: 630 mm Clearance between grinding motor and table: 585 mm Max. load on table: 500 Kg Supply voltage: 400 V Weight: 4550 Kg EQUIPMENT INCLUDED: x1 HI-CUT pack including: -work area protection -exhaust system with electrostatic air filter -fire protection system (to be assessed by a qualified body) -automatic paper tape filtration unit x1 grinding motor x1 cable for grinding motor Machine visible under power in our premises by appointment.

Request for a quote

KRAFFTER MACHINE TOOLS

France

Year of manufacturing : 1996 Stroke X axis: 650 mm Max. Stroke speed X axis: 4000 mm/min Working feed X axis: 0 - 1800 mm/min Stroke Y axis: 450 mm Working feed Y axis: 0 - 1800 mm/min Stroke Z axis: 130 mm Min. Stroke speed Z axis: 0.5 mm/min Max. Stroke speed Z axis: 12000 mm/min Stroke frequency Z axis: max. 4 Hz Stroke W axis: 500 mm Planetary speed C axis: 5 - 250 rpm Max. Stroke speed W axis: 800 mm/min Stroke U axis (radial feed): 5.5 mm Distance between columns: 750 mm Table length: 770 mm Table width: 630 mm Clearance between grinding motor and table: 585 mm Max. load on table: 500 Kg Supply voltage: 400 V Weight: 4550 Kg + ADDITIONAL INFORMATION Machine visible under power in our premises by appointment. Price on request, loading on truck included. Possibility of shipping Worldwide. The information on this page has been obtained by the best of our ability. Therefore, its accuracy can not be guaranteed.

Request for a quote

GLOMACHT BV

Netherlands

Willing to sell or buy used or new industrial machinery? Share your power and let GLOMACHT get in charge of everything. For more info, please contact us: contact@glomacht.com Buy / Sell your machinery with us! SHARE YOUR USED POWER!

Request for a quote

DOREY

France

Width 100 mm Bedplate and load bearing structure with easy dismounting Support cross members Main shaft group Front and rear plate unit Feed roller unit with micrometric adjustment Main drive unit Brush and feed rollers unit driven by servomotor Grinding wheel dressing unit gr. 36 Pneumatic control panel Electrical control panel Electronic programmable logic unit using a dedicated software for total management of machine functions with dust suction device CZ Dust Collector C4 Metering device (Alarm with light to inform about maintenance periods)

Request for a quote

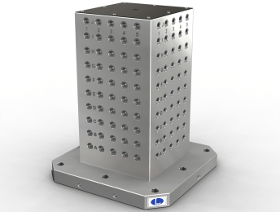

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Threaded Holes for Side-Location Cast iron gridded cube with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Holes for side location to allow precise loading and setting up of the tombstone.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Threaded Holes for Side-Location Cast iron gridded cube with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Holes for side location to allow precise loading and setting up of the tombstone.

Request for a quote

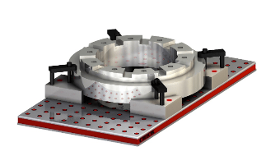

1ST MACHINE TOOL ACCESSORIES

United Kingdom

T-Slots to allow for Flexible use for Fixturing Products Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. T-Slot pattern to allow for easy flexible set-up of fixturing components. Ground flat with Locating Holes for precise loading and quick location.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Threaded Holes for Side-Location X-Shape allows for more side Clearance for Machining Cast iron gridded cross profile Tooling Column with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Holes for side location to allow precise loading and setting up of the tombstone.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Sturdy Cast Iron Design Ground Flat and Parallel Modular quick change subplate to suit the BP13 modular cube. This plate is gridded to accept standard fixturing parts./

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. Plain to allow for machining of hole patterns and features required for special jigs or fixtures. Ground flat with Locating Holes for precise loading and quick set-up.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat Five High Accuracy Location Holes Cast Iron Sub Plate to suit rotary table or indexer. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat with Locating Holes for precise loading and quick location.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

A Chick Workholding Foundation Plate is tailored to fit the machine’s specifications. A standard grid pattern to simplify designing, cataloguing and utilisation of fixtures, providing consistency and repeatability to set-ups. Length and width tailored to the machine’s work envelope. Precision ground cast iron to 35mm thick. 50mm spaced holes, drilled and tapped, for use as both location and hold down. Sealed with chip plugs. An alpha-numeric labelling system. Minimises set up time from workholding system to system. Machine interface mounting holes, customised for each machining centre.

Request for a quote

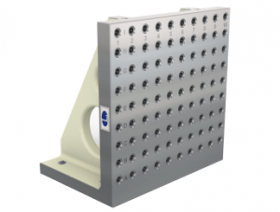

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Cast iron gridded angle plate .Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. To suit verticle or horizontal machining centre applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Cast iron gridded angle plate .Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. To suit verticle or horizontal machining centre applications.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat and Parallel Locating Holes for easy Set-Up Cast iron plain fixture plate with mounting holes. Plain to allow for the machining of hole patterns and features required for specific fixtures. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Machinable to accept required hole pattern Ground Flat and Parallel Locating Holes for easy Set-Up Cast iron plain fixture plate with mounting holes. Plain to allow for the machining of hole patterns and features required for specific fixtures. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Allignment Busing and Thread Hole for Quick Accurate Set-ups Ground Flat and Parallel Locating Holes for easy Location Cast iron fixture plate with mounting holes. Grid pattern with allignment bushes and threaded inserts for ease of set-up. Ground flat parallel and perpendicular for accuracy. Two dowel holes allow for precise loading and setting up of the fixture plate.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Two Magazines in One - A step by step magazine for material up to 6mm and a gravity magazine for larger material Flexibility - Re-tooling takes minutes thanks to the use of snap-in guide channels High Performance - Works with closed calibrated channels ensuring high speeds with reliability, precison & silent operation Headstock Synchronicity - Fitted with a mechanical system that give both reliability, precision & a reduction in idle times The Elite is a premium bar feeder, simple to use. It is designed to meet the needs of those who are looking for the best possible performance and reliability, accurate selection of thin bars, adaptability when changeovers are needed, and a guarantee of rigidity even for the most challenging machining applications. * Based on indicative data. Material, Bar Length & Parameters can significantly affect this time ** Max Capacity

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Rigidity - The new Boss HD (Heavy Duty) structure guarantees the barfeed absorbs a larger quantity of vibration Operator interface - The new enhanced operator interface has new user friendly functions. Touch screen is available Non productive times - Bar change and feeding times have been drastically reduced increasing productivity Magazine capacity - Several options available to increase capacity for longer unattended production The BOSS 552 HD is an automatic bar feeder for bars with diameters between 5 and 51 mm, ideal for working with fixed headstock and sliding headstock lathes, available for bar lengths from 700 to 6,380 mm. It guarantees the maximum reliability without any compromises. * Based on indicative data. Material, Bar Length & Parameters can significantly affect this time

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Rigidity - The new Boss HD (Heavy Duty) structure guarantees the barfeed absorbs a larger quantity of vibration Operator interface - The new enhanced operator interface has new user friendly functions. Touch screen is available Non productive times - Bar change and feeding times have been drastically reduced increasing productivity Magazine capacity - Several options available to increase capacity for longer unattended production The BOSS 338 HD is an automatic bar feeder for bars with diameters between 3 and 38 mm, ideal for working with fixed headstock and sliding headstock lathes, available for bar lengths from 700 to 6,380 mm. It guarantees the maximum reliability without any compromises. * Based on indicative data. Material, Bar Length & Parameters can significantly affect this time

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Adapt standard expanding mandrels for blind holes Compatible with metric ID Xpansion clamps Milling and turning versions available Manual actuators for use with the Miteebite range of ID Xpansion clamps. These Actuators are specifically designed for gripping the ID of blind holes but may also be incorporated in many applications that require a straight draw actuated 90 degrees from the drive screw. They are capable of gripping on bores ranging from 4.1mm to 35.3mm using our standard ID clamps. Both styles of Actuators come completely assembled with the heat-treated cylinders tapped for the following clamp drive screws: M2, M4, M6, M8, M10 and M12.

Request for a quoteResults for

Grinding - Import exportNumber of results

36 ProductsCountries

Company type