- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forming

Results for

Forming - Import export

TECHNIC MACHINES

Turkey

As Technic Machines, we supply all kind of roll forming machines. We have in our portfolio some standard roll former machine lines but also we provide customs solutions for our customers Roll former machine is pretty common machine in metal industry and each work can have small differences because of the local market demand on roll forming shape. We provide exact solution for our customers with different width, thicknesses and shapes of roll forming. We supply for our customers as standard roll form machine, Customs Roll Former Machine Glazed and Step Tile Making Machine Roof Panel Roll Forming Machine Trapezoidal Sheet Roll Forming Machine Corrugated Sheet Roll Forming Machine Rolling Shutter Roll Former Machine Drywall and Gypsum Channel Making Machine Just contact with us for your other roll forming machine request, we will provide customs solution according to your roll former machine research.

Request for a quote

TECHNIC MACHINES

Turkey

Rolling Shutter Forming Machine is for manufacturing the roller shutters with different width, thickness and roller shutter forming according to customer’s request. Rolling shutter raw material can be strong steel or such as aluminium as to final customers. The main using area of roller shutters are shops, houses industrial constructions, super markets and other constructions. Design and widths can be change of shutter door forming, also sheet metal thickness can be different according to market target price demand or safety requirements. We design for different thickness and working range of our roller shutter door roll forming machine, also general working width of rolling shutter roll forming will be between 80 to 130 mm, but it can be different according to local markets. Roller Shutter Door Roll Forming Machine Units Coil Decoiler Rolling Shutter Door Forming Unit Roller Shutter Door Punching Unit Rolling Shutter Door Fly Cutting Unit Shutter Stacking Unit

Request for a quote

TECHNIC MACHINES

Turkey

Roof panel roll former machine is pretty common almost all countries. Shape of metal roof panel can be different by countries but we provide also different shapes for our customers. Also we can provide different cassette or double layer on our roof panel machine. Roof Panel Roll Forming Machine's Units - Coil Decoiler Machine - Roll Forming Unit - Cutting Shear - Control Panel - Stacking Unit Just contact with us for your request, we will provide the optimum solutions.

Request for a quote

ACTON S.A.

France

Rondelles inox pour constructions bois forme R / Washers for wood constructions form R

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Large Quantities: produced as cold formed parts (so-called multi-station presses), which require high output volumes in order to achieve a reasonable price parts Small Quantities: Produced as turned parts - the economic adjustment to small batch sizes Fields of application: For thermoplastics, duroplastics, light alloys, metal compounds. Industrial consumers: Electrical industry, plastics processing industry, sheet metal processing industry, telecommunications, tank- and container construction.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Compact short-stroke cylinder with a diameter of 20 in a rectangular block shape with mounting holes on the front.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The AT multi-turn actuators are characterized by their compact shape and clear design. Integrated grooves for sensor mounting. Angle of rotation from 0° to 180°.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

The economic adjustment to small batch sizes, we meet with our turned parts for the direct assembly in plastics and die-cast products. Any thread forms such as, thread-tapping (DIN7500), thread cutting (DIN 7513-7516) or KTG for direct screw in plastics are realized cost-effectively. Advantage is the elimination of high tooling costs, since no counter-thread in the workpiece (eg threaded inserts, nuts, etc.) is required because the direct assembly takes place directly into the workpiece. Only a given tube is required in order to screw it directly. Our turned parts replace previously cold formed parts used (so-called multi-station presses) which require high output volumes in order to achieve a reasonable price parts.

Request for a quote

NORELEM FRANCE

France

Tempered, black oxidised. Precision diameters ground.

Request for a quote

NORELEM FRANCE

France

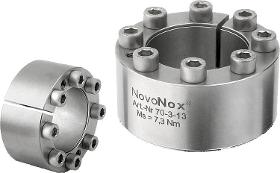

Coupling stainless steel 1.4057. Screws stainless steel 1.4301. For applications that require a small construction volume and low surface pressure. The keyless locking coupling can be fully recessed in a hub connection. for shaft diameters 6 20 mm suitable for hubs with low wall thickness minimum axial offset possible selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Particularly compact selfcentring keyless locking coupling without axial offset. for shaft diameters from 8 to 85 mm for medium torques suitable for hubs with low wall thickness no axial offset selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Shrink disc to connect a hollow hub to a shaft. They are mounted on the OD of the hub and generate pressure on the hub wall by reducing the ID with wedgeformed rings, creating a press fit between the hub and shaft. They are suitable for static, dynamic and shock loads. for extremely high torques no axial shaft/hub offset when assembling selfcentring The version 23380014072 has high tensile ISO 4762 screws. Assembly Remove existing transportation locks. Clean and lightly oil shaft, internal and external hub diameters. Do not use MoS2 or grease. Slide shrink disc onto hub. Then slide unit (shrink disc/hub) onto shaft and position correctly. Gently tighten clamping screws one after the other by hand. Then use a torque wrench to tighten the clamping screws crosswise in several increments to the defined tightening torque MS. 1st increment approx. 33% MS 2nd increment approx. 66% MS

Request for a quote

NORELEM FRANCE

France

Unshielded system. The magnets can be mounted by pressfit or gluing. 1) magnetic face

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Machine for shaping and punching holes in catheters. Working speed: Up to 5 cycles/min, about 1200 cycles/h.

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

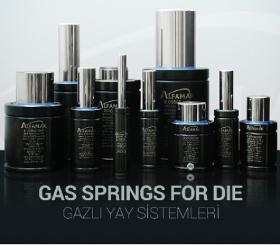

ALFAMAK is one of Turkey's leading gas spring manufacturers. Established in 2003, our company has been operating in the industry for 19 years and has gained a reputation for success. Gas spring is a new technology which comes instead of standard steel or polyurethane springs. A gas spring has a container of compressed Nitrogen gas with Piston Rod , Bush, Rod Rings, Valve etc. The Gas Springs are used in Cold Stamping industry to form, cut and fix the sheet metal inside the die. Many auxiliary materials are used for different purposes in the gas spring. Rod wiper, rod guide and rod seal are used on the inner surface of the bush. The purpose of the rod wiper is to prevent the oil and chips in the die from entering the gas spring. The rod guide is used to carry the load in case of axial force on the rod during use. The most important auxiliary material for sealing is rod/piston seal. It directly affects the performance of the product by keeping the gas in the gas spring.

Request for a quote

NORELEM FRANCE

France

Ball end locating pins are specially designed to ease the locating process. The tendency to jam, caused by the locating hole not being at right angles to the pin or by the pushing force not being parallel to the pin axis, is minimized by the ball-end form (see illustration).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORELEM FRANCE

France

The rest pads can be used both as a stable and precise support and as a stop. The pin form of the rest pad also allows it to be used with components with constricted support points.

Request for a quote

YADA GIDA VE DIS TICARET

Turkey

Form tea with apricot, 12 packs per pallet.

Request for a quote

YADA GIDA VE DIS TICARET

Turkey

Mixed form tea, 12 packs per pallet.

Request for a quote

TECHNIC MACHINES

Turkey

Complete turnkey roll forming machine line according to the finished final product with all necessary equipment, such as uncoiler, feeder, roll former, hydraulic or eccentric presses, stacking unit, etc. We offer standard models of roll forming machines as well as specific models according to the final product requirements of our customers. Some of our standard roll forming machine models are: • Warehouse racks and shelves • Market racks and shelves • Building and construction • C, U, Z, and Sigma (track and stud) • Guardrail • Roll-up door forming machine • Roof panel forming machine • Standing seam • Wall panel • Drywall and plasterboard • Snap lock • Cable tray • Scaffolding Just contact us for any roll forming machine you need, and we will find the optimal solution.

Request for a quote

TECHNIC MACHINES

Turkey

We provide for our customers different combinations of cable tray roll former machine line. Such as feeding system solutions from coil or sheet or different working parameters for cable tray roll forming machine. And also we produce our cable tray production line with different final cable tray design as to customer's request. With different cable tray width, thickness, height or with different cable tray punching solutions according to our customer’s final cable tray design. Cable Tray Roll Forming Line Units – Cable Tray Press Feeding Unit – Cable Tray Punching Unit – Cable Tray Roll Forming Unit – Cable Tray Cutting Unit – Cable Tray Coupling Unit Solutions for Cable Tray Making Machine Cable Trays have no standard sizes. Sizes can be between 50 – 1200 mm width and can be between 25 – 100 mm flange height. - Light Duty Cable Tray Roll Former - Medium Duty Cable Tray Roll Forming Line - Heavy Duty – Cable Tray Production Line

Request for a quote

VIRMER

Netherlands

WATTSAN 1325 BASIC fiber laser machine is an economical and practical machine for cutting thin sheet metal. The metal cutting machine works with stainless and carbon steel, copper, aluminum, titanium and other materials. This machine is often purchased for manufacture, such as aviation, astronautics and mechanical engineering. We can install Maxphotonics / Raycus / IPG fiber laser emitter for choice. The main advantage of a fiber laser over a gas laser is its high speed and accuracy of operation, as well as durability: the life of the ignition unit is 100,000 hours, i.e. years of continuous operation. The machine has a working table 1300x2500 mm. WATTSAN 1325 BASIC laser machine is a high-precision device with a reliable control system. It has a high-quality fiber laser emitter. Of course, such a device will last a long time, because the declared service life of the frame is 20 years.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY has a rotary device for cutting cylindrical products. This machine is purchased for cutting steel tubes, galvanized and stainless steel, aluminum, brass and other materials. The machine is most often used in aviation, aerospace and mechanical engineering, as well as for the manufacture of auto parts, advertising products and household appliances. You can install a radiator of any power: 300/500/750/1000/1500/2000/3000/4000/5000 Watts. Important: the machine is equipped with a protective cabin with a power of 1000 Watts. Optional fiber laser emitter: Max / Raycus / IPG. Each of them is distinguished by high accuracy and speed of work, durability, but there are also differences. IPG is considered a premium model, it gives the best result and speed. The service life of the emitter ignition unit is about 100 000 hours. The protective glass for the lens, which must be changed at least once a month. The lens itself needs to be renewed approximately once a year.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY CABINE is a powerful fiber laser machine, also known as a tube cutter. The device is equipped with a protective cabin for safe operation, as well as a rotary device. The rotary device takes the capabilities of your equipment to a whole new level. You can use the metal cutter like a regular cutter, and in a few minutes switch to the task of cutting tubes. The protective cabin is installed on machines from 1000 watts. This ensures the safety of the laser cutting operator, as well as minimizes the dangers of external influences. The machine is equipped with a fiber optic emitter: Max or Raycus or IPG. Such an emitter will last up to 100 000 hours of the most intensive work. If we talk about the intensity of work — the stand is weighted, crushes vibrations and will last 20 years, according to the manufacturer's information.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 TABLECHANGE is a high precision fiber laser cutting machine. It is equipped with an automatic change table. This design allows you to quickly change sheet metal while another workpiece is being cut. Such a system saves time and money for its owners. Such a machine has long been used in aircraft construction, mechanical engineering, light industry and medical equipment. The machine is equipped with a laser solid-state emitter to choose from: Max / Raycus / IPG. All three have proven themselves: Max is standard, Raycus is more expensive and better, and IPG is considered a premium series. All three types of emitters have a resource of about 100,000 hours. The automatic change table has a size of 1500×3000 mm for metal. The bed is made with a margin of safety, and the heavy weight dampens vibrations. Vibration mounts can be installed for added stability.

Request for a quote

VIRMER

Netherlands

Fiber metal cutting machine WATTSAN 1325 TABLECHANGE is a large and high-precision machine for cutting stainless and carbon steel, copper, aluminum, galvanized plates and other materials. On this machine, it is possible to install emitters of the following powers: 300/500/750/1000 Watts, and from 1500-5000 Watts with a protective cabin. One of the main advantages of all fiber lasers is durability: the life of the ignition unit reaches 100 000 hours. And this is about 10 years of continuous work. The manufacturer also claims that the bed of this machine can last 20 years. There are two options for the working field for this machine: 1300x2500 mm and 1500x3000 mm (1530 TABLECHANGE). For smaller workpieces, the 1300x2500 mm option is suitable; for industrial production, it is recommended to purchase a larger working area. If you have any doubts about the choice of the working field, please contact our specialists for advice.

Request for a quote

FATRA A.S.

Czech Rep.

Formed packages Fatra company is the traditional Czech manufacturer of packages moulded from non-plasticized PVC foil. Our product portfolio includes cups, trays, and lids (including its possible imprint). Our offer also includes ice-cream cake containers Processed materials PVC-U PVC (polyvinylchloride) is a universal, proven, and reliable material. It was developed in the thirties of the 20th century as one of the first synthetic materials – plastics. It is a material well workable using various technologies, e.g. rolling, extrusion, depositing, or casting, therefore it is predestined for wide range of applications. PVC has a unique combination of features, which can be further modified in various ways using processing additives. PVC is usually classified into softened - called most frequently PVC-P, ands hard - called PVC-U. Polyvinylchloride ranks among materials that can be recycled well and reused in the manufacture of products. Recyclable PVC is marked PVC-R. In general,...

Request for a quote

ID ALLOYS - DISTRIBUTEUR ALLIAGES DE NICKEL ET COBALT

France

You’ll find here the main materials and forms that are in our stock. In addition to these materials, we aim to answer your needs in the best adapted way by offering all requested services: cutting – kitting – dedicated and/or consigned stocks – tests … If you are looking for a material or a service that you don’t see here, feel free to ask. Via our knowledge of the market and its actors, we’ll do our utmost to help you find a solution: info@idalloys.fr

Request for a quoteResults for

Forming - Import exportNumber of results

71 ProductsCountries

Company type

Category

- Steels and metals - forming and cutting (6)

- Screws (6)

- Rolling mills - machinery and installations (3)

- Coupling screws (3)

- Herb teas (2)

- Vehicles - mechanical components and parts (2)

- Forming - steels and metals (1)

- Metal industrial presses (1)

- Electrical & Electronic Components (1)

- Bending machine tools (1)

- Cosmetics (1)

- Dried fruits (1)

- Electronics - import-export (1)

- Food industry packaging machinery (1)

- Additives, food (1)