- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- equipment for the chemical industry

Results for

Equipment for the chemical industry - Import export

POFI-ENGINEERING

Luxembourg

Mixing concept Description: The mixer drum (Drums or rotator) TF220 allows to rotate a drum of 220 litters to homogenize the contents. The drum is laid on a support inclined slightly rearwardly so as to improve the mixing in the drum. It is firmly held by a retaining hook in the upper part and two retaining st raps on its periphery. The mixing time is set as a front view of the control box by means of a programmable timer. The assembly is protected in an enclosure fenced and secure. The drum turns off automatically in the upright posi-tion so as to simplify the installation or removal of drums. In a simple design, it is robust and requires very little maintenance.

Request for a quote

SHUTDOWN FASTENERS AND SPECIALS BELGIUM

Belgium

Furthermore, we are an experienced partner for customized production solutions, in the field of atypical flanges, rings and special forged components. As your competent partner, we enable you to purchase your entire specification from one single source. As a trading and manufacturing enterprise, our know-how is there for your benefit. Our strong customer-oriented approach challenges our team’s experience to guarantee skilled support in every phase of business. We take pride in long-standing relationship with our customers and our manufacturers. In-house testing facilities We perform all mechanical and chemical tests according to the applicable standards such as: mechanical Tensile tests, hardness and impact tests (destructive testing), product analysis, PMI, UT, HIC (Non-destructive testing) or any other customer requirement.

Request for a quote

SHUTDOWN FASTENERS AND SPECIALS BELGIUM

Belgium

SFSB SUPPLIES FLANGES, FITTINGS & PIPES TO THE CHEMICAL, PETROCHEMICAL, OIL AND GAS INDUSTRIES, THE OFFSHORE, VESSEL BUILDERS, PIPING CONTRACTORS AND ENGINEERING AS WELL AS COMPONENTS FOR POWER GENERATORS AND NAVAL CONSTRUCTIONS. Furthermore, we are an experienced partner for customized production solutions, in the field of atypical flanges, rings and special forged components. As your competent partner, we enable you to purchase your entire specification from one single source. As a trading and manufacturing enterprise, our know-how is there for your benefit. Our strong customer-oriented approach challenges our team’s experience to guarantee skilled support in every phase of business. We take pride in long-standing relationship with our customers and our manufacturers.

Request for a quote

MPT DOSING GMBH

Germany

Homogenizing large tank volumes, mixing-in additives during the production of lubrication oil and suspending solids in a liquid phase are typical applications for the pneumatic pulse-mixing technology of PULSAIR. The process, patented worldwide, is based on an injection of an adjustable pressure pulse underneath an accumulator plate, installed on the bottom of the mixing tank. The injected pressurized air forms a big air bubble, soaring within the tank and displacing the surrounding liquid. Meanwhile negative pressure is generated underneath the bubble, sucking the surrounding material. This produces in the tank a vertical flow directed upwards, adjustable according to the requirements by varying the pulse length and the pulse duration. Contrary to mechanical agitators the height of the tank is very marginal. No moving parts or shaft bearings are in the tank.

Request for a quote

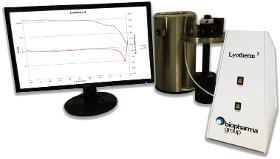

BIOPHARMA GROUP

United Kingdom

Rocket Synergy 4D is for drying single large volumes of solvent, from a few litres up to approximately 100 litres. The system can also be used for a single batch of up to 5 litres. Rocket Synergy 4D provides fast, safe evaporation for solvents with a boiling point of up to 165°C (DMF) and can easily dry aqueous samples. Automatic evaporation of volumes up to 100 litres Eliminates bumping or foaming Easy vessel manipulation with no glassware to handle Safe, easy product recovery and system cleaning

Request for a quote

BIOPHARMA GROUP

United Kingdom

Frozen state solutions are a critical product stage or end product in a variety of industries, including freeze drying, pharmaceuticals, food storage and biotech. The Lyotherm3 combines electrical and thermal techniques. This unique dual analysis adds a new dimension to the data of this critical stage. Impedance Analysis (Zsinφ) is a fixed frequency dielectric analysis providing an indication of the sample tracks molecular mobility, including events not picked up by thermal methods like DTA or DSC Differential Thermal Analysis (DTA) measures the difference in temperature between a sample and a reference, highlighting exothermic and endothermic events e.g. crystallisation, eutectic melting and glass transitions Combining DTA and Impedance analysis means Lyotherm is more sensitive to changes within the frozen structure than other exclusively thermal techniques.

Request for a quote

BIOPHARMA GROUP

United Kingdom

Kinematics & Controls Corporation’s compact modular powder filling systems have proved to be popular in environments where not only precise material dosing is required, but also in areas where companies seek to make the process more efficient, maximising potential product throughputs. Powder is picked up by vacuum and compacted to a constant density within a cylindrical fill chamber. It is subsequently dispensed by the application of low-level, positive-pressure air. The use of a pre-defined vacuum force, compressing the powder sample to a uniform/ even density is the key to achieving the high level of repeat dose accuracy. Cumbersome, time-consuming, hand-weighing is thus eliminated. A wide range of standard gun sizes and filters with various porosities are offered for use with the variety of powders and container sizes which the customer’s process might demand. A custom, 8-up, Micro-Well kit can also be specified, to streamline the filling of 96-cavity well plates.

Request for a quote

BIOPHARMA GROUP

United Kingdom

The Series 3 HT evaporator range from Genevac represents the ultimate in solvent removal technology. Genevac-014 A Solution for High Throughput Evaporation Genevac HT series evaporators are the ideal solution for parallel evaporation bottlenecks in high throughput and production laboratories having high performance and high sample capacities. The unique design of the multi-layer rotor ensures efficient use of valuable laboratory bench space as well as high performance and high throughput evaporation. This proven design has now been updated with the latest version, the Series 3.

Request for a quote

BIOPHARMA GROUP

United Kingdom

The Emulsiflex range of high pressure homogenisers from Avestin are ideal for a wide range of applications, commonly use d within the pharmaceutical, biotechnology and fine chemicals industries. These include cell lysis, particle size reduction, nanoparticles, emulsions (emulsification), and liposome preparation. Additionally, it offers reliable, consistent processing at adjustable pressures of up to 45,000 psi, Both air-powered and electrically-powered systems are available, and options include filter/extruder attachments, temperature control mechanisms and automatic pressure control. The unique Emulsiflex design ensures that there are no ‘O’-rings or gaskets in the entire path of the product. This means less risk of contamination, easier cleaning and no leakage.

Request for a quote

INDEPETRO

Iran

Xylenes are produced with different processes. When in refineries, oil cuts enter the reforming units, aromatic compounds comprise a great proportion of the outflow material. Separating this flow into its components, accounts for more than 70 percent of global xylene supply. Also in the steam cracking process in olefin units, some quantity of Mixed Xylene is produced. In addition, disproportioning Toluene into Benzene and Xylene and treating Pyrolysis Gasoline are also different ways to produce Mixed Xylene. Mixed xylenes are the second-most-important aromatic product in terms of world consumption for chemical manufacture, ranking behind benzene and ahead of toluene. Mixed xylenes refers to the equilibrium mixture of four isomers with the same C8H10 chemical formula. The isomers in order of natural occurrence are meta-xylene, ortho-xylene, para-xylene, and ethyl-benzene.

Request for a quote

INDEPETRO

Iran

Toluene is a liquid chemical compound utilized in the manufacturing of many commercial products, including paints and glues. Colorless and insoluble in water, toluene can be dangerous when its fumes are inhaled, causing neurological damage and intoxication. Because of this, toluene is sometimes abused as an inhalant drug. Individuals who use paints and thinners frequently, like those who work with such products professionally, wear face masks in order to minimize the inhalation of toluene. Beyond its uses, however, toluene’s chemical structure is quite interesting of its own accord. Toluene demand growth in Europe is expected to be positive but low at a rate less than GDP. Demand will get a fillip in 2009 following the start-up of ExxonMobil’s new TDP unit in Rotterdam, the Netherlands.

Request for a quote

INDEPETRO

Iran

Diisocyanates are a family of chemical building blocks mainly used to make polyurethane products, such as rigid and flexible foams, coatings, adhesives, sealants and elastomers. Many of the products we rely upon every day are safer and more comfortable through the use of polyurethanes made possible by diisocyanates. Polyurethane chemistry is complex, but the basics are relatively easy to understand. Polyurethanes are produced by combining diisocyanates with polyols and other chemical additives. Because a variety of diisocyanates and a wide range of polyols can be used to produce polyurethane and the speed of the reaction can be adjusted, a broad spectrum of materials can be produced to meet specific application needs. Diisocyanates are important in the production of countless products, particularly in the transportation and construction industries. TDI is used primarily in the production of flexible foams.

Request for a quote

INDEPETRO

Iran

Hydrochloric Acid is a corrosive, strong mineral acid with many industrial uses. A colorless, highly pungent solution of hydrogen chloride (HCl) in water, when it reacts with an organic base it forms a hydrochloride salt. With major production starting in the Industrial Revolution, hydrochloric acid is used in the chemical industry as a chemical reagent in the large-scale production of vinyl chloride for PVC plastic, and MDI/TDI for polyurethane. It has numerous smaller-scale applications, including household cleaning, production of gelatin and other food additives, descaling, and leather processing. About 20 million tonnes of hydrochloric acid are produced worldwide annually. It is also found naturally in gastric acid.

Request for a quote

INDEPETRO

Iran

Sodium hydroxide, otherwise called Caustic Soda, is an inorganic compound with chemical formula NaOH. It is called caustic soda because it is highly corrosive in nature. It is available in many forms in the industry, and the most common forms are caustic soda flakes and caustic soda pearls. This product has several industrial applications but it is highly reactive, so it has to be used carefully lest, it can cause skin irritation. Caustic Soda is a strong base with a wide range of applications in different industries. Worldwide, the major users of caustic soda are the aluminum industry, pulp & paper and the chemical industry. The main applications are water treatment and water purification, as cleaning agent, or a wide range of uses in chemical industry like starch production or for the desulphurization in the petrochemical industry.

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

With the FPM (once F&G) explosion-proof low voltage motors, we offer you a complete programme of safe, reliable, durable and economically viable motors in protection IP 54 to IP 65, and Ex d and Ex de. All motors are also available as special versions to suit your individual requirements. The quality control system which is certified to DIN/ISO 9000, guarantees a consistent high level of quality. But there''s even more: As an environmentally friendly company, ATB Motorentechnik GmbH is also certified according to the EU-Enviornmental Audit (EEC 1836/93). We supply from our existing stock Kalefeld F&G- flameproof motors / hazardous motors Ex de IIC T4 High Efficiency IE2 in frame size 80 - 200 ( 2 and 4 -poles ) 0, 75 - 37 kW. All motors on stock are with Ptc thermistors. Other frame sizes and versions are available within 6-8 weeks after receipt of order . FPM Explosion Proof Motors / hazardous motors available in IE1 and IE2 High Efficiency High Voltage Motors high voltage motors in flameproof enclosures which provide reliable drive power in industrial plants and equipment in the chemical, petrochemical and offshore industries. The extreme operating conditions which prevail in these areas demand the highest levels of operational safety and reliability. This motor is particularly low in noise and is equipped with built-in temperature sensors for monitoring the bearings. An additional terminal box for PT 100, anti-condensation heaters, etc. is also provided Performance range 160 - 800 kW Ex-proof II 2 G Ex de IIC T4

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quote

ARFOC- GESTÃO DE INVESTIMENTOS UNIP. LDA

Portugal

Analysis of the order, shipping after sample parameterization, definition of the delivery model to the customer and a variable period of 30 to 60 days after order confirmation is estimated in order to deliver

Request for a quoteResults for

Equipment for the chemical industry - Import exportNumber of results

39 ProductsCountries

Company type