- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting - steels and metals

Results for

Cutting - steels and metals - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High Accuracy Taper and External Diameter Wide range of Sizes Available These reduction bushes allow for the fitting of boring bars and drills with a tapered shaft. All sizes are manufactured in a range of capacities. The sleeves are hardened and ground for a good fit for both the holder and the shaft.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High Accuracy Taper and External Diameter Wide range of Sizes Available These reduction bushes allow for the fitting of boring bars and drills with a tapered shaft. All sizes are manufactured in a range of capacities. The sleeves are hardened and ground for a good fit for both the holder and the shaft.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High Accuracy Taper and External Diameter Wide range of Sizes Available These reduction bushes allow for the fitting of boring bars and drills with a tapered shaft. All sizes are manufactured in a range of capacities. The sleeves are hardened and ground for a good fit for both the holder and the shaft.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High Accuracy Taper and External Diameter Wide range of Sizes Available These reduction bushes allow for the fitting of boring bars and drills with a tapered shaft. All sizes are manufactured in a range of capacities. The sleeves are hardened and ground for a good fit for both the holder and the shaft.

Request for a quote

SCHOCK GROUP

Germany

Your project is in the best hands at SCHOCK. Our experienced engineers use state-of-the-art methods to plan all resources and guarantee on-time production. In addition, we supervise your tool over its entire life cycle. In mold and tool making, we work with high-quality milling machines, wire and die-sinking EDM machines, and modern CNC-controlled grinding machines.

Request for a quote

SCHOCK GROUP

Germany

Due to own production sites with modern machinery your customer requirements can be effectively considered and realized.

Request for a quote

SCHOCK GROUP

Germany

At our main logistics hub in Germany, we stock a constantly growing range of over 150,000 products in more than 200 product categories for industry and trade for the whole of Europe.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK manufactures sophisticated 1- and 2-component plastic parts with modern machinery. Our competences also include the corresponding mold and tool design.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK’s core competencies include roll forming technology with a large number of integrated processes. With our roll forming technology we are able to produce individual and high-precision profiles or complete assemblies for our customers.

Request for a quote

SCHOCK GROUP

Germany

Our process-controlled assembly machining up to the manufacture and delivery of complex assemblies rounds off the range of production and services within SCHOCK.

Request for a quote

SCHOCK GROUP

Germany

With SCHOCK powder coating we realize high-performance and visually appealing product surfaces with long-term corrosion protection and individual color design.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK develops custom-engineered solutions that successfully stand out from the market with innovative ideas and comfortable features. With long experience and expertise, we design high-quality products with individual additional benefits

Request for a quote

SCHOCK GROUP

Germany

SCHOCK has many years of expertise in the assembly and manufacture of complex assemblies. Our customers can therefore also purchase a finished assembly from SCHOCK instead of many individual components

Request for a quote

SCHOCK GROUP

Germany

SCHOCK manufactures sophisticated plastic parts for the highest requirements with a modern machinery line consisting of injection molding machines, quick slide machines and multi-component injection molding machines

Request for a quote

SCHOCK GROUP

Germany

SCHOCK is the specialist in the production of cold-rolled profiles according to individual customer requirements. With a wide range of different technologies, we manufacture special profiles as customized functional elements up to complete assemblies.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK has been a successful innovator and manufacturer of ball bearing telescopic rails and linear slide systems for decades. Our products impress with their precision, high load ratings and long service life.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

During re-machining, a cutting tool is used to remove material from a workpiece in order to shape or surface it as required. We offer re-machining (turning, twisting) as wage work. The following machining operations we offer: Turn thin stem, pins and tips Screw punctures, approaches and undercuts Heads of screws / cold shaped parts machining process (turning) further machining operations are possible on request. Our curve-controlled automatic Audrema lathes offer you further possibilities of finishing cold-moulded parts. These automatic lathes are designed to achieve maximum precision and reproducibility at high throughputs. Short loading and unloading times permit economical production of medium-sized and large series.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VIRMER

Netherlands

WATTSAN 1530 TABLECHANGE is a high precision fiber laser cutting machine. It is equipped with an automatic change table. This design allows you to quickly change sheet metal while another workpiece is being cut. Such a system saves time and money for its owners. Such a machine has long been used in aircraft construction, mechanical engineering, light industry and medical equipment. The machine is equipped with a laser solid-state emitter to choose from: Max / Raycus / IPG. All three have proven themselves: Max is standard, Raycus is more expensive and better, and IPG is considered a premium series. All three types of emitters have a resource of about 100,000 hours. The automatic change table has a size of 1500×3000 mm for metal. The bed is made with a margin of safety, and the heavy weight dampens vibrations. Vibration mounts can be installed for added stability.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY CABINE is a powerful fiber laser machine, also known as a tube cutter. The device is equipped with a protective cabin for safe operation, as well as a rotary device. The rotary device takes the capabilities of your equipment to a whole new level. You can use the metal cutter like a regular cutter, and in a few minutes switch to the task of cutting tubes. The protective cabin is installed on machines from 1000 watts. This ensures the safety of the laser cutting operator, as well as minimizes the dangers of external influences. The machine is equipped with a fiber optic emitter: Max or Raycus or IPG. Such an emitter will last up to 100 000 hours of the most intensive work. If we talk about the intensity of work — the stand is weighted, crushes vibrations and will last 20 years, according to the manufacturer's information.

Request for a quote

VIRMER

Netherlands

WATTSAN 1530 ROTATORY has a rotary device for cutting cylindrical products. This machine is purchased for cutting steel tubes, galvanized and stainless steel, aluminum, brass and other materials. The machine is most often used in aviation, aerospace and mechanical engineering, as well as for the manufacture of auto parts, advertising products and household appliances. You can install a radiator of any power: 300/500/750/1000/1500/2000/3000/4000/5000 Watts. Important: the machine is equipped with a protective cabin with a power of 1000 Watts. Optional fiber laser emitter: Max / Raycus / IPG. Each of them is distinguished by high accuracy and speed of work, durability, but there are also differences. IPG is considered a premium model, it gives the best result and speed. The service life of the emitter ignition unit is about 100 000 hours. The protective glass for the lens, which must be changed at least once a month. The lens itself needs to be renewed approximately once a year.

Request for a quote

VIRMER

Netherlands

Fiber metal cutting machine WATTSAN 1325 TABLECHANGE is a large and high-precision machine for cutting stainless and carbon steel, copper, aluminum, galvanized plates and other materials. On this machine, it is possible to install emitters of the following powers: 300/500/750/1000 Watts, and from 1500-5000 Watts with a protective cabin. One of the main advantages of all fiber lasers is durability: the life of the ignition unit reaches 100 000 hours. And this is about 10 years of continuous work. The manufacturer also claims that the bed of this machine can last 20 years. There are two options for the working field for this machine: 1300x2500 mm and 1500x3000 mm (1530 TABLECHANGE). For smaller workpieces, the 1300x2500 mm option is suitable; for industrial production, it is recommended to purchase a larger working area. If you have any doubts about the choice of the working field, please contact our specialists for advice.

Request for a quote

PROSAW LIMITED

United Kingdom

This Geka Hydracrop 110S is a versatile and economic universal steelworker with 2 independent hydraulic cylinders, 2 areas and 5 workstations. It is suitable for punching profiles and for mounting special equipment. It benefits from a greater speed backed by a powerful hydraulic unit. Geka Hydracrop 110S Standard Details Machines driven by two cylinders 5 work stations, fitted with tools for L, shearing, round and square bars, rectangular notching and punching Quick change punch Flat bar shearing table with adjustable guides 2 simultaneous work stations Greater speed backed by a powerful hydraulic unit Special equipment for approaching at reduced pressure and slow speed Precision punching table with X & Y measuring stops Precision notching table with X & Y measuring stops Ready for production pack comprising: One meter "touch & cut" length stop with fine adjusting Lamp for enhanced vision of cutting zones 10 sets of round punches and dies

Request for a quote

COLORICIO.SRL

Romania

Round steel / Square steel, Flat steel , L cornier profile , IPE Steel and much more

Request for a quote

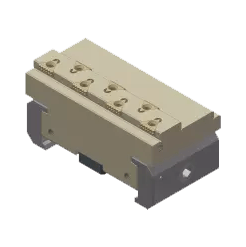

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick change jaws for fast setups Hardened and precision ground for wear resistance and accuracy Ideal for demanding clamping conditions and high clamping forces Adapts the OneLok to accept older bolt-on soft jaws Jaw spacers for OneLok that fit 5OL1540 and 5OL1550 and well as the previous generation of OneLok. These jaws are hardened and precision ground for strength and accuracy. The BoltFast mechanism means they can be changed in seconds. The holes in these jaws allow the re-use of standard bolt-on jaws.

Request for a quote

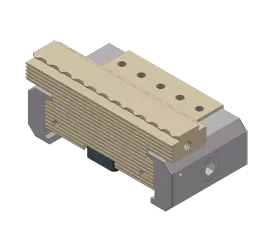

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick Change Mechanism Hardened for Longevity Clamping Surface is Grooved to Avoid Marking Component Custom Sizes Available For clamping workpieces that must not be damaged. The clamping surface is grooved and not ribbed. This results in reducing the potential for marking components. The stepped jaw is hardened approx. 0.2 mm deep. The accuracy of the surface with respect to the serration is +/- 0.02 mm. For greater accuracy, the jaws must be ground in tension on the vice.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Switch between jaws and faceplates in seconds Clamp more complex workpieces Clamp more components at a time Load faceplates outside the machine for better efficiency Faceplates form the base for a fixture to mount directly to the QwikLOK. They are ideal for complex workpieces that cannot be mounted in soft jaws and also allow smaller workpieces to be clamped in larger quantities. Combine a faceplate with simple workstops and clamps to buld a multi component fixture that can be loaded outside the machine. Add another identical faceplate and you have a manual pallet changing system to virtuallly eliminate loading time.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Change jaws in seconds and complete a full setup in a few minutes Precise loction of jaws means your datum is preserved every time you remove the jaws. Once a job is setup, it stays setup. Machinable workholding means complex shaped workpieces are easy to grip Single station jaws can grip larger workpieces with just a quick jaw change Single Station Machinable Jaw Sets increase the flexibility of your system by eliminating the need to completely switch fixtures for jobs requiring greater holding capacity. Simply QwikChange the jaws and the set-up is ready in minutes. These jaws are compatible with 1030 Qwik-loks and 1030 Multi-Loks and are available in a range of sizes. All jaws are available as sets or individually.

Request for a quote

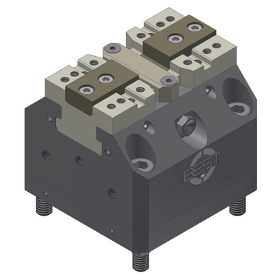

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Repetition Accuracy of 5 micron Extremely High Clamp Forces Low wear due to Nitrogen Hardened Surfaces Suitable for Internal or External Clamping BEST hydraulic centric vices are a no compromise solution to repeating and long running 4th and 5th axis workholding. BEST have focused on the production of high accuracy, high rigidity vices. These vices are suitable for both internal and external clamping. They offer very high clamping forces and repeatability of 0.005mm and a centring accuracy of 0.01mm. The Hydraulic vices also have the following options: Clamp Path Monitoring, Fixed Jaw, Central Lubrication System and Positive Air Pressure to prevent swarf ingress.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Quick Change Mechanism Hardened for Longevity Gripping Serration is 3mm deep to Reduce Waste Material Requires Low Clamping for during Machining, Reducing Deformation Gripper jaws can reduce the risk of the part being torn out under high machining forces. The penetrating tips produce a very high holding force even at low clamping force.

Request for a quoteResults for

Cutting - steels and metals - Import exportNumber of results

48 ProductsCompany type