- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coils

Results for

Coils - Import export

HONSEL-GROUP

Germany

High-strength for design and repair Coil threaded inserts or “coils” are an outstanding solution for achieving highstrength joints in parts made from low-strength materials (e.g. aluminium lightweight constructions). At the same time, high wear resistance is guaranteed. Furthermore, the inserts are ideally suited for the repair of damaged threads. Very simple handling Coils consist of a specially formed and coiled wire with a driver pin that can be removed after installation and can be fitted quickly and easily in just a few steps. Choose the right threaded insert for your application from over 500 sizes. Do you need a special form? No problem! Together with you, we can develop the required coil threaded insert and produce it in the highest quality.

Request for a quote

HONSEL-GROUP

Germany

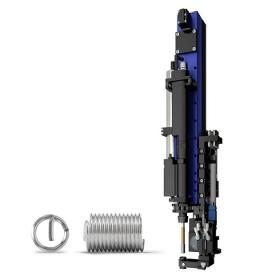

Coil screw system 2G for automated and partially automated installation of wire thread inserts. Due to the slim construction, screw systems can be placed close to each other. This leads to more efficient use of existing production areas and thus to greater economic efficiency in production. The electric linear motor is very fast at up to 3.2 m/s and enables cycle times in production to be optimized. — Screwdriver Bosch BG2 — Floating screwdriver bearings — Integrated coil transfer with rotary gripper — Linear motor — Camera

Request for a quote

HONSEL-GROUP

Germany

The HONSEL COIL "cone" can be installed in the same way as a coil with tab. No additional or special tools are required for process-reliable installation. When the HONSEL COIL "cone" is screwed onto the installation spindle, the conical portion of the wire thread insert creates a clamping effect between the installation tool and the coil. This ensures a stable installation process into the work piece. Advantages: — tab-free and therefore optimally designed for e-mobility due to no risk of tab debris. — Shallower blind hole depths can be realized — Subsequent processes are no longer necessary (breaking and removing of the installation tab) — No thread skipping during installation — Cycle time reduction of 20-30 % per installation — No special tools required for the installation process — The installation process improves due to the conical portion

Request for a quote

TECHNIC MACHINES

Turkey

Our coil feeder and straightener machine is for custom solutions on press feeding equipment’s results. Also we are targeting to provide precision results on decoiler straightener and feeder machine's press feeding solutions. Our coil feeder is provide perfect results for press feeding process. Coil decoiler, straightener and feeder machines are manufactured as synchronised machine system but separated or as single machine body for coil decoiler, straightener and feeder. We provide coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

TECHNIC MACHINES

Turkey

Our coil slitter machine has working thickness range from the coil is beginning from 0.2 mm and up to 20 mm and working width up to 2.100 mm As to requests or slitting work specifications of our customers we offer perfect combinations to our customers for their metal slitter machine researches. We offer different coil slitting line range options, for example heavy duty coil slitting machine, medium duty coil slitter machine or light duty metal slitter machine. We offer alternatives for matching exact metal slitting line machine parameters according to our customer’s demand. Also according to requested working raw material we offer different solutions for our customers for their metal slitting machine research. - Light Duty Metal Slitter Machine - Medium Duty Slitting Line Machine - Heavy Duty Coil Slitting Machine Line

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil straightener feeder machine with compact single body and for working precision feeding and without damage on sheet metal surface. Our coil straightener feeder machines provide to have working possibility with high speed and precision sheet metal feeding and straightening results during press feeding. We have as alternative for coil straightener feeder machine standard models. And we design and provide for different request specific coil feeder straightener machines. We supply our coil feeder straightener machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil straightener feeder machine solution.

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil straightener machine for having perfect straightening results and without damage on sheet metal surface. Our coil straightener machines provide to have working possibility with high speed and precision sheet metal straightening results during press feeding. We have as alternative for coil straightener machine standard models. And we design and provide for different request specific coil straightener machines. We supply our coil straightener machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil straightener machine solution.

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil feeder machine for working precision feeding and without damage on sheet metal surface. Our coil feeder machines provide to have working possibility with high speed and precision sheet metal feeding results during press feeding. We have as alternative for coil feeder machine standard models. And we design and provide for different request specific coil feeder machines. We supply our coil feeder machines as to our customer's requests and needs, according the working sheet raw material, thickness and width. We check our customer’s final target product and requested production capacity, then we offer the optimum solution coil feeder machine solution.

Request for a quote

TECHNIC MACHINES

Turkey

Our compact coil feeder and straightener machine is for custom solutions on press feeding equipment’s results with minimum necessary space solution. Also we are targeting to provide precision results on decoiler straightener and feeder machine's press feeding solutions. Our compact coil feeder is provide perfect results for press feeding process. Coil decoiler, straightener and feeder machines are manufactured as synchronised machine system and as single machine body for coil decoiler, straightener and feeder. Also straightener feeder has single body design on our compact coil feeder machine system. We provide compact coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

TECHNIC MACHINES

Turkey

The coil-fed laser offers great advantages in coil laser cutting processes with the help of the continuous coil-fed laser cutting system. With the aid of a perfect construction and advanced software of the coil-fed laser machine, we provide our customers with precision, accuracy, and the possibility of rapid production from the coil to the laser cutting system. Advantages of the coil-fed laser cutting machine: • Results with minimal waste • Lower electricity consumption • Reduced labor costs • High production capacity • Low maintenance cost • NO investment in tools required • Maximum cutting flexibility • Clean, precise, and continuous cutting • Cutting bed design according to customer demand • Possibility of special design in coil-fed laser machine

Request for a quote

TECHNIC MACHINES

Turkey

We provide for more economical solution our this Cut to Length Machine model We can consider that It is more feasible for small metal workshops, it requires smaller space and provide low production capacity is we compare with our other Coil Cut to Length Line models We provide with our this model Cut to Length Line Machine, compact system with single chassis straightener and feeder unit and also this model Metal Cut to Length Machine model is with no pit system. We have always optimum solution on our machine models for our customer's researches. Just contact with us for your Coil Cut to Length Line research.

Request for a quote

TECHNIC MACHINES

Turkey

This model cut to length machine line is more feasible for heavy duty work Also it has fast production speed if we compare with our compact model If you are searching coil cut to length machine with high speed and heavy work, our this model is best solution It is the professional, fast and feasible for heavy coil cut to length line work Cut to Length Line with pit system is preferred by professional steel working companies and trading companies Just contact with us for your Cut to Length Machine research, we will find the optimum solution for your need

Request for a quote

TECHNIC MACHINES

Turkey

The reason of using the Zig-Zag Coil Feeder Machine System is minimizing the scrap and waste during press works with the advantage of 2 axes movable feeding. The moveable 2 axes zig-zag coil feeder can easily adapt the majority presses. Our zig-zag coil feeder and straightener machine is for custom solutions on press feeding equipment’s results. Also we are targeting to provide precision results on zig-zag decoiler straightener and feeder machine's press feeding solutions. Our zig -zag coil feeder is provide the minimum scrap solution for press feeding process. Zig-Zag coil decoiler, straightener and feeder machines are manufactured as synchronised machine system. We provide zig-zag coil feeder machine systems with custom solutions according to our customers final product needs. Such as with different thickness and width range and decoiler tonnage capacity.

Request for a quote

NORELEM FRANCE

France

Hardened to 780 ±40 HV 10 and ground. Without leadin groove. Note All bushes have the bore size marked on the upper face, e.g. 10. Diameters D1 over 15 mm increase in size by 0.5 mm. Dowels or coiled spring pins together with DIN 1731 flathead screws can be used in place of the stop pin.

Request for a quote

TECHNIC MACHINES

Turkey

Our cut to length machine has working thickness range from the coil is beginning from 0.2 mm and up to 20 mm and working width up to 2.100 mm As to requests or metal cut to length work specifications of our customers, we offer perfect combinations to our customers for their metal cut to length machine researches. We offer different coil cut to length line range options, for example heavy duty cut to length machine, medium duty metal cut to length machine or light duty metal cut to length line. We offer alternatives for matching exact cut to length line machine parameters according to our customer’s demand. Also according to requested working raw material we offer different solutions for our customers for their sheet metal CTL line machine research. - Light Duty Cut to Length Machine - Medium Duty Cut to Length Line Machine - Heavy Duty Coil Cut to Length Machine

Request for a quote

TECHNIC MACHINES

Turkey

We design our coil decoiler machine for to do coil uncoiling work for heavy duty or light duty metal coils with loading car system. We offer for our customers hydraulic coil decoiler for heavy duty coils, mechanical coil decoiler for light duty coils. Also we have double head coil decoilers as different solution. Hydraulic decoiler machine is for more heavier coils, we provide until 30 tons Mechanical decoiler machine is for more lighter coils, we provide until 4 tons Double head decoiler machine is designed for not losing time during coil changing, we provide until 15 tons

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

It provides excellent bulk and stiffness in an easy to tear product. Polyester Non-Woven laminates are puncture resistant and highly conformable making these tapes ideal for wrapping around sharp corners and edges. Applications • Ground and barrier insulation for electrical motors, generators, etc. • Outer wrapping, tabbing, harnessing and anchoring leads for electrical transformers, coils, etc

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HEINZE & STRENG GMBH

Germany

Unique bow design according to the T-beam principle. This allows enormous weight savings (about 40%) without loss of robustness. Lower weight makes handling easier during replacement. Maximum energy savings and longer rotor bearing lifespan thanks to extreme weight reduction. Additional cast steel strands in the bow edges provide optimal protection in the event of wire breakages – especially with hard wires. Wire guides depending on product and customer requirements: Roller, ceramic, carbide or tempered steel guides possible.

Request for a quote

ARSILAC

France

TECHNICAL SPECIFICATIONS - Reference : 004661 - Model : SPAIP5000SER - Effective capacity : 4880 Litres - 304 stainless steel wine rack - Flat bottom with 4% slope - DIN 15 stainless steel tasting tap - Level tap diameter 20 with stainless steel protection - Partial drain with 100x100 square flange and MACON 40 outlet valve - Total drain with 100x100 square flange and MACON 40 outlet valve - Rectangular door 420 x 530 mm positioned at bottom of shell - 3 adjustable stainless steel feet (500 mm high) - Air kit complete with pump and pressure gauge - Air float complete in 316L stainless steel - Gallows - Lifting winch - Clock thermometer - Probe socket - Stainless steel ladder support bar - Vacuum lifting rings - Cooling coil with 4 turns on shell H. 560 mm - Cooling coil with 2 turns on shell H. 300 mm DIMENSIONS - Height 3700 mm (with jib) - Height 3000 mm (without bracket) - Outside diameter: 1666 mm - Inside diameter: 1600 mm

Request for a quote

ARSILAC

France

TECHNICAL SPECIFICATIONS - 304 stainless steel tank - SPAIP SER 2300 model - Effective capacity: 2297 litres - 304 stainless steel wine rack - Flat bottom with 4 % slope - Bottom thickness : 2.0 mm - shell : 1.5 mm - Floating cap in 316L stainless steel - Complete pneumatic system - Swivel arm with stainless steel handle - Winch for lifting the floating cap - 3 stainless steel feet H. 500 mm adjustable + 80 mm adjustable - Rectangular door 420x530 mm flush with bottom of shell - Swivel bracket with stainless steel handle - Cooling coil with 4 rings on the shell - 2 additional cooling rings on the door - Sensor pocket positioned at the rear of the tank - Clock thermometer with immersion sleeve DIMENSIONS - Diameter 1400 mm - Height (shell) 1500 mm - Height (total) 2600 mm (with bracket) - Height of bowl + feet (500 mm): 2000 mm (without support)

Request for a quote

ARNO FUCHS GMBH

Germany

Disc diameter Ø 360 mm or Ø 600 mm other diametres on enquiry Bent for Unwinding (for drums): up to Ø 550 mm width max. 200 mm

Request for a quote

DOMINO SIGN

France

For the manufacture of your signs, Domino Sign stocks coils of black prepainted aluminum ranging from 25mm to 200mm in thickness. It is possible to order reels of flat bands without minimum purchase by mixing the dimensions. Black prepainted aluminum Thickness 11/10 Exterior black RAL 9005 Raw anodized interior 165m spools

Request for a quote

DOMINO SIGN

France

For the manufacture of your signs, Domino Sign stocks white prepainted aluminum coils ranging from 25mm to 200mm in thickness. It is possible to order reels of flat bands without minimum purchase by mixing the dimensions. White prepainted aluminum 10/10 thickness 165m spools

Request for a quote

DOMINO SIGN

France

For the manufacture of your signs, Domino Sign stocks mirror or brushed stainless steel coils ranging from 25mm to 200mm in thickness. It is possible to order reels of flat bands without minimum purchase by mixing the dimensions . Stainless steel Grade EN430 with PVC protective film Stainless steel mirror Brushed stainless steel 78m spool

Request for a quote

DOMINO SIGN

France

For the manufacture of your signs, Domino Sign stocks coils of raw aluminum ranging from 25mm to 200mm in thickness. It is possible to order reels of flat bands without minimum purchase by mixing the dimensions. Raw aluminum 12/10 165m spools

Request for a quote

DOMINO SIGN

France

EasySign Bender e automatically creates the edges and listels of your letters from aluminum and stainless steel coils. His system, fully automated , bend and cut the following profiles: Letter Box Profile Alu Letter Form Profile Profile Bar Aluminum and stainless steel flat belts, 25 to 120 mm high. Letter Box Profile Alu is a process combining productivity and aesthetic finish. It allows you to make box letters with illuminated plexiglass faces without having to use the listel for the faces, or the fixing screws for the backs, thanks to the stainless steel EasyClip clips. Profile Bar is an innovative process for easily making box letters with illuminated plexiglass faces. Indeed, this letter is assembled without welding. EasySign Bender e comes with SDSBenderCAD software, allowing you to process and optimize your DXF files on your workstations.

Request for a quote

SADEV INOX

France

Grade : 316L polished Wire diameter: 0,15 mm Ref : 13815 Product : Spool Lenght: 500 meters Weight: 70 gr

Request for a quote

TITANEX GMBH

Switzerland

ASTM F 560 or ASTM B 708

Request for a quote

IMPEXRON GMBH

Germany

AVS ROMER Item.Nr. : 616832 Country of origin: Germany HS Code: 84812090 Weight: 0.948 kg

Request for a quoteResults for

Coils - Import exportNumber of results

32 ProductsCompany type

Category

- Metal straightening machines (6)

- Coils and solenoids (6)

- Metallurgy - machinery and installations (3)

- Cutters (2)

- Nuts and bolts (2)

- Wine fermentation tanks (2)

- Cutting - machine tools (1)

- Steel sheets and strips (1)

- Steel, carbon (1)

- Tools & Hardware (1)

- Galvanization - steels and metals (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Bending machine tools (1)

- Cold rolled steel strips (1)

- Drums, barrels and kegs - metal (1)