- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping parts

Results for

Clamping parts - Import export

NORELEM FRANCE

France

Enter the desired lever colour here. The standard colours are: Black grey clamping lever, traffic red push button. Orange clamping lever, black grey push button. Traffic red clamping lever, black grey push button. Where L ≥ 60 mm the thread length is 60 mm. On request: Other threads, screw lengths and special versions. Dimension “H1” available in other lengths at extra charge. Drawing reference: 1) flat point DIN 78

Request for a quote

NORELEM FRANCE

France

Sliding carriage Base structure in extruded section, aluminium EN AW6060. Sliding elements Maintenance free plain bearing iglidur® J. Version Eloxalcoated E6/EV1. Black thermoplastic Note With a low rate of inerita, high accelerations and short term extreme speeds up to 30 m/s are possible. DryLin® T linear glide guides are resistant to dirt and corrosion and are adjustable, maintenancefree and quiet. Application temperature max. 80 °C. As no lubricants are used they are recommended for use in food, medical, and clean room technologies. Manual clamping was developed for simple functions. Polymer under constant pressure has a tendency to creep which causes a decrease in clamping force over time (up to 70%), which means that no safetyrelevant parts should be clamped. Suitable guide rails see 21200. Drawing reference 1) manual clamping

Request for a quote

NORELEM FRANCE

France

The workholding magnets 090602010 to 090602030 consist of a permanent magnetic system with fine pole divisions (4 mm) which are effective on two or three faces. To clamp extremely thin steel parts we recommend the magnet 090602040 with the finest pole division of 1.3 mm. The magnetic lifespan of the workholding magnets under conditions prevailant in industrial machining is unlimited. Approximately half the height of the workholding magnets can be ground down or polished away with no significant impairment of the magnetic strength.

Request for a quote

REP INTERNATIONAL

France

Horizontal range H49, H59, H610 The range is designed for easy implementation of automated production processes, namely injection moulding of more or less sophisticated technical parts. Clamping force available from 1,950 kN to 4,000 kN. Shown above press types H49, H59 and H610 (with and without brush).

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Can be used for 1st Operation only Deadlength Actuation Eleminates part movement when Clamping Case hardened, optimising the rigidity, strength and durability. Varibore Collets have a large range allowing for easy holding of Rough Bar Klamp CRS60 collet chucks are suitable for collets which have a large gripping range. Allowing the collet chuck to handle very rough and unfinished bar, preparing it for a high accuracy second operation. Workpiece remains in a fixed position during actuation, allowing for precise z-axis positioning. A tapered sleeve is pushed forward, compressing the collet and gripping the workpiece

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

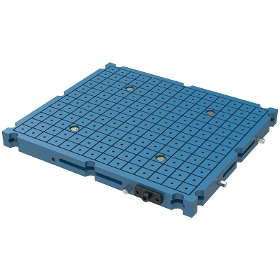

Can be used with or without pallet Can run from vacuum generator or dedicated pump Can be mounted on a magnet for grinding applications Matrix on top surface can be used for traditional clamping or part location DESCRIPTION Possibly the most universal multi-functional vacuum system in today’s market, this system has several unique features to meet your vacuum workholding needs. Each Multi-Power vacuum table has 4 ports to allow for multi component clamping. The top surface is textured for extra holding force and has a matrix of threaded holes to combine vacuum and traditional clamping methods as well as the ability to mount pallets. The bottom surface includes 6 embedded steel washers to allow the unit to be mounted on a magnet for grinding applications. The Multi-Power vacuum table can be equipped with multiple vacuum generators when additional holding force is required and multiple vacuum tables can operate from a single vacuum source.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Ideal for Secondary Operations on lathe parts Clamp body made of mild steel for machinability Side screw clamping for blind holes Easily clamped in a lathe chuck The Side-Loc Xpansion Clamp is actuated from the side, making it perfect for blind hole applications. The Side-Loc Xpansion Clamp is designed in two styles, one for milling operations and one for lathe applications. The milling vesrion has a precision machined base for precise location in fixture plates and the lathe version has a 25.4mm shank for gripping in a chuck.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Ideal for Secondary Operations on lathe parts Clamp body made of mild steel for machinability Heat-treated and coated screw for long life Longer screws available for hydraulic applications The ID Xpansion™ clamp is the ideal solution to hold parts on an inside diameter for high density machining on vertical or horizontal machining centers. It can also be used as an expanding mandrel on a lathe. These machinable clamps are produced in 12 sizes and can hold internal diameters from under 5mm to almost 254mm. All are manufactured from 12L14 steel with black oxide coating except the largest diameter which is manufactured from 7075-T6 aluminum. The flange diameter of the clamp is held to a close tolerance for precision locating in a machined pocket on work cubes and fixture plates. The customer machines the mild steel clamp to match the bore of the part ensuring a proper fit.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compatible with large, readily available, range of jaws Two stage gripping gives clamping and seating of part Base jaws do not protrude on z axis Sealed body designKitagawa chucks are manufactured from high grade alloy steel. The Kitagawa DL Series are the 1st chuck with two stage gipping action, firstly parallel clamping then pull back action for work seating.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Can be used for 1st and 2nd Operation Deadlength Actuation Eleminates part movement when Clamping Case hardened, optimising the rigidity, strength and durability. Uses 3 Different Types of Collet Klamp CRL60 collet chucks are suitable for spring, varibore and rubberflex collets increasing its flexibility. Varibore and rubberflex collets allow rough, unfinished bar to be machined in the first operation and spring collets can be used for high accuracy in the second operation. Workpiece remains in a fixed position during actuation allowing for precise z-axis positioning. A tapered sleeve is pushed forward, compressing the collet and gripping the workpiece. Maximum Capacity can be increased to 65mm using Rubberflex Collets

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Compatible with large, readily available, range of jaws Two stage gripping gives clamping and seating of part Base jaws do not protrude on z axis Sealed body design Kitagawa chucks are manufactured from high grade alloy steel. The Kitagawa DL Series are the 1st chuck with two stage gipping action, firstly parallel clamping then pull back action for work seating.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Aggressive machining operations while clamping on as little as 1.5mm Ideal for difficult applications or proto-type work Jaws to suit round or complex profiles as well as regular shapes Available for 6" and 8" vices Increase the functionality of your standard 150mm and 200mm vices. This combo kit is a simple bolt on system that will allow you to perform aggressive machining operations on Square, round or complex parts while clamping on as little as 1.5mm. This set includes a set of TalonGrip jaws (Sets includes 4 TalonGrips, 1 stop and M5 screws) and a set of VersaGrip jaws (Set includes 4 VersaGrip with M5 Screws).

Request for a quoteResults for

Clamping parts - Import exportNumber of results

13 ProductsCountries

Company type