- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- change machines

Results for

Change machines - Import export

APD MAQMASTER

Spain

Special aluminum alloy body honed with long-lasting electrostatic paint. Special legs to avoid vibration. Great versatility and easy handling. Upper front template with double copy. The pocketing of any figure can be through without needing to change the machining face. Engine power: 1.5 HP 220/380 V Spindle speed: 15,350 rpm Fresolin diameters: d=5mm D=8mm Milling capacity: 255 x 110 x 130 mm. (X AND Z) Fresolin Ø 5 mm. (1 piece) Service keys Lubrication system Measurement stop equipment OPTIONAL Special copy template

Request for a quote

TECHNIC MACHINES

Turkey

Our PU, PIR and PUF sandwich panel production machines have different capacity and production thickness from 30 mm to 200 mm and also sandwich panel making machine speed from 6 meters/minute to 16 meters/minute with 50 mm sandwich panel thickness production. Our sandwich panel machine lines are the optimum solution in the market with quality and performance matching parameters. Sandwich Panel Production Line Units Roll Decoiler Machine Feeding Unit Film Coating Unit Roll Forming Machine Rolling Conveyor Unit Pre-Heating Foaming Machine Double Belt Pressing Machine Rolling Conveyer Fly Cutting Unit Runout Table Automatic Vacuum Stacker Automatic Packaging Machine Metal raw material can be changed on sandwich panel machines, as aluminium, metal sheet, pre-painted metal sheets etc.

Request for a quote

VIRMER

Netherlands

WATTSAN М9 1325 has a working area of 2500х1300х200 mm and a T-slot slatted table. The complete set of the machine includes a water-cooled spindle with the power of 7.5 kW and ER-32 collet chuck. The portal is driven by YASKAWA servomotor and steppers. The milling machine is controlled by an operator through Weihong NCStudio control system. Unlike the junior model, this machine supports the automatic tool change option. The machine body is a welded structure made of steel profile; the weight of the machine is 1500 kg. The maximum travel speed along the axes is 50 000 mm/min; the maximum travel speed during operation is 20 000 mm/min. The spindle speed reaches 24 000 rpm. The machine is controlled by NCStudio software. On request, the machine can be equipped with a vacuum table, a DSP-controller, a Syntec control system, an aspiration system, a more powerful spindle or an additional spindle, a rotary device to process cylindrical objects, and a tool sensor.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Accepts a variety of workholders Excellent workpiece accessibility In the case where you can’t mount the head directly to your machine table, please use this mounting plate. We can supply a blank that is customisable and also manufacture a special mounting plate just for you. For more information, please feel free to contact us.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

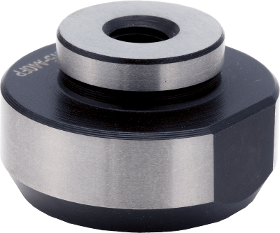

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Excellent workpiece accessibility Workpiece centralizing on flang work holders. Flange work holders These central bosses are used for workpiece location on the Klamp range of flange work holders.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Uses the HSK-A type, time-proven tool holder shank to connect the head and the work-piece holder. Off-line setup in advance allows quick work-piece changing, minimizing machine downtime. Excellent workpiece accessibility The dovetail clamping work-holder with the HSK head works with heavy-duty milling. All Swift Klamp Dovetail work holders are attached to the workpiece usinga simple dovetail. Setup is quick, easy and dovetail work holders only require the minimum of material to hold the workpiece. That means less waste, easy preparation, and no distortion to the workpiece.Dovetail machining of the work-piece clamping area using an angular cutter is required prior to machining

Request for a quote

APER DIAMOND SL

Spain

-Manufacturing year: 2011. -Serial number: 140020037 -Real working hours: 1.650 aprox. (control unit shows another working hours because the control module of the machine was changed 3 years ago). -Good condition -Price: 19.500€ (without tool)

Request for a quoteResults for

Change machines - Import exportNumber of results

8 ProductsCountries

Company type

Category

- Machine tools - metal machining (4)

- Cars - electrical and electronic parts and components (2)

- Milling - machine tools (1)

- Coupling screws (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Metallurgy - machinery and installations (1)

- Screw cutting - steels and metals (1)

- Used machines and equipment (1)