- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminum railings

Results for

Aluminum railings - Import export

NORELEM FRANCE

France

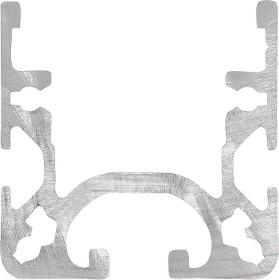

Extruded section, aluminium EN AW6060. Version Hard anodised aluminium, 50 µm. Hardness 500 HV. Note The aluminium guide rail has good thermal conductivity and importantly heats only at continuously very high speeds. ** lengths L2 = 20 mm * and L = 500 mm included L2 and L only available in full mm.

Request for a quote

GESTION CONTAINER

France

Volume: 67 m 3 Surface area: 26 m 2 Structure: Corten and fully welded stainless steel Floor: Flat aluminum / T-shaped aluminum rail Insulation: 70 mm polyurethane Fork passage: no fork passage Gas: new R134A Power required: 12 KW Electric supply: 380V TRI Connection socket: 3 p + earth 32A Temperature: -25°C to +25°C Door opening : 270° Weight: 4,650 kg Maximum loading weight: 29,350 kg Number of European pallets: 23.

Request for a quote

GESTION CONTAINER

France

Volume: 12 m 3 Surface area: 5 m 2 Structure: Corten and stainless steel fully welded Floor: Flat aluminum / T-shaped aluminum rail Insulation: 70 mm polyurethane Fork passage: 2,050 mm Gas: new R134A Power required: 12 KW Electric supply: 380V TRI Connection socket: 3 p + earth 32A Temperature: -25°C to +25°C Door opening : 270° Weight: 2,600 kg Maximum loading weight: 12,400 kg Number of European pallets: 4

Request for a quote

IGUS® GMBH

Germany

DryLin® telescopic rails Total extensions Partial extensions Over-extensions DryLin® telescopic rails DryLin® telescopic rails with locking function Detent in start, medium and end position Freely selectable locking position DryLin® telescope - wth locking mechanism Completely lubricant-free linear extensions in continuous stroke lengths of 100mm to 600mm - maximum pulled-out length: 1200mm. The telescopic systems consist of anodized aluminum guide rails and a gliding block made of the proven iglidur material. By the incompounded solid lubricants, iglidur tribopolymers enable dry operation in every application. The advantage - besides being maintenance-free - is the carefree use in clean hygienic environments. No oil or fat can be transmitted to other products, clothing or people. Applications even in cleanroom air showers were already implemented. But the dry operation also has advantages in the dirt accumulation area. Dirt particles do not stick to the guide and do not become a sticky mass. As an option, all telescopic guides can be delivered with a detent in start-medium-end position. Requirements for individually positioned locking positions can be met. Detailed view: DryLin® telescopic rail in a guard door adjustment. DryLin® telescopic rails Total extensions Partial extensions Over-extensions DryLin® telescopic rails DryLin® telescopic rails with locking function Detent in start, medium and end position Freely selectable locking position DryLin® telescope - wth locking mechanism

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

NORELEM FRANCE

France

The aluminium profile is matched to the roller elements. As a result, roller rails and roller tracks can be realised. The different inserts permit modular and flexible setup.

Request for a quote

NORELEM FRANCE

France

The aluminium profile is matched to the roller elements. As a result, roller rails and roller tracks can be realised. The different inserts permit modular and flexible setup.

Request for a quote

NORELEM FRANCE

France

Backstop steel. Axis steel. Cage polyamide, carbonfibre reinforced. Version Electro zincplated Cage black. Note The backstop element is matched to the aluminium profiles for roller rails and can be mounted on them quickly and easily. It prevents reverse movements of items on the roller tracks. No tools required. Suitable for aluminium profiles Type B and I.

Request for a quote

NORELEM FRANCE

France

Body, extruded aluminium section. Bearing housing and slide, aluminium. Profile guide rail and guide carriage, steel. Toothed belt, polyurethane with steel cord reinforcement. Version Body natural colour anodised Bearing housing and slide, black anodised. Tracks of the profile guide rail, inductively hardened and ground. Note Compact and flexible linear actuators with toothed belt drive. The body consists of a selfsupporting aluminium extruded section with integrated profile guide rail. This rail system is able to absorb highest forces from all directions, is lowwear, and is optimised for moving large masses. Slots are located on the outer sides of the aluminium profile, ensuring easy, reliable assembly and enabling accessories mounted. Proximity switches can be positioned and fastened in the upper Tslot. The aluminium profile is fully compatible with our standard I series profiles.

Request for a quote

NORELEM FRANCE

France

These brackets are used to hang aluminium profiles for roller rails in a round profile. A mounting set is supplied.

Request for a quote

NORELEM FRANCE

France

Carriage body zinc. Plastic bearing material iglidur® J. Rails anodised aluminium. Version Body chromed. Guide rail natural colour anodised. Note Miniature slide guides are maintenancefree and corrosion resistant. Very high speeds and accelerations are possible due to the low weight. Applicable temperature max. 80 °C. Miniature slide guides are insensitive to dust and are ideal for dry running. ** length L2 = 30 mm and * L = 1000 mm included L2 and L only available in full mm.

Request for a quote

NORELEM FRANCE

France

Ball stainless steel. Housing steel. Cage polyamide, carbonfibre reinforced. These ball transfer units are matched to the aluminium profiles for roller rails and can be mounted on them quickly and easily. For flexible movements in two dimensions. With a lowwear and lowfriction ball rollers. No tools required. Suitable for aluminium profiles Type B and I.

Request for a quote

NORELEM FRANCE

France

Roller and cage polyamide, glassbead reinforced. Steel axis. Cage black. Roller available in different colours. The roller elements are matched to the aluminium profiles for roller rails and can be mounted on them quickly and easily. No tools required. The compact design with a small centre distance is optimally designed for the lowvibration conveyance of sensitive items. Suitable for aluminium profiles Type B and I.

Request for a quote

MANNEQUINS SHOPPING

France

Philips black led spot on track 3000 Kelvin three-phase Robust look for shop lighting with this track-mounted led spot box. Easy to combine with the CAN version. Available in different colours, but also with different coloured reflectors. Elegant as shown with the white housing and aluminium reflector. Mounting rail system. Features: Lumen 3250 Light coloured arm white Kelvin 3000K LED Philips Fortimo SLM Philips Xitanium Mini driver Lens Lens 16 ° -26 ° -36 ° -60 ° Circuits 50000 x Don't hesitate to contact us for more information about our pro lighting ranges for your points of sale. Our LED spot projectors come with a 3-year guarantee, lifetime 50,000 hours. Are you looking for a modular solution that allows you to adapt your lighting to the configuration and layout of your sales area, or do you simply not have a false ceiling?

Request for a quote

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Shaft support rail unit SMTSN 12-T1-WV length precisely lengths to the millimetre, choosable up to 6000mm, with rail in aluminium and shaft in hardened, quality: Cf53-chrome plated (1.1213) This system you can combined with all open (look the "o" in the name of article) housing units, see categorie: http://lineareasy.com.de/shop/index.php/cat/c12_Gehaeuseeinheiten.html Urgent notes for order: The excat required length of the unit please enter in the bottom field. If you give us no note there, we supply automatically the maximum length of this article. The type SMTSN we deliver assembled to you. Product data unit: Dimensions: Type d A h +/- 0,15 V N1 N2 d1 d2 W (°) E T weight./kg* SMTSN-12 12 40 22 5 8,0 5,0 4,5 4,5 5,8 50 29 75 0,52 *weight in the table it relates to a rail with length 600mm without shaft. depending on the length of the shaft support rail unit, the rail is composed of several individual section T5 min = 20mm the weight of the unit you´ll see down on this side material of shaft support: Aluminium Product data shaft: Material shaft: Cf53-chrome plated Chrome layer thickness: ca. 10 my Chrome layer hardness: >= 800HV Hardened: 59-65 HRC Rht min.0,6 Grounded Tol. h7 (0-18my) Surface roughness: Ra <= 0,3 Weight (shaft only): 0,89kg/m Straightness:0,2mm/m Predrilled: see the table Chamfer: on both sides of the shaft appr. 1 - 2mm x 30° (depending the diameter of the shaft)

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Shaft support rail unit SMTSN 12-T1-W length precisely lengths to the millimetre, choosable up to 6000mm, with rail in aluminium and shaft in hardened, quality: stainless steel X46Cr13 (1.4034) This system you can combined with all open (look the "o" in the name of article) housing units, see categorie: http://lineareasy.com.de/shop/index.php/cat/c12_Gehaeuseeinheiten.html Urgent notes for order: The excat required length of the unit please enter in the bottom field. If you give us no note there, we supply automatically the maximum length of this article. The type SMTSN we deliver assembled to you. Product data unit: Dimensions: Type d A h +/- 0,15 V N1 N2 d1 d2 W (°) E T weight./kg* SMTSN-12 12 40 22 5 8,0 5,0 4,5 4,5 5,8 50 29 75 0,52 *weight in the table it relates to a rail with length 600mm without shaft. depending on the length of the shaft support rail unit, the rail is composed of several individual section T5 min = 20mm the weight of the unit you´ll see down on this side material of shaft support: Aluminium Product data shaft: Material shaft: stainless steel X46Cr13 Hardened: 52-56 HRC Rht min.0,6 Grounded Tol. h6 (0-11my) Surface roughness: Ra <= 0,3 Weight (shaft only): 0,89kg/m Straightness:0,2mm/m Predrilled: see the table Chamfer: on both sides of the shaft appr. 1 - 2mm x 30° (depending the diameter of the shaft)

Do you sell or make similar products?

Sign up to europages and have your products listed

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Shaft support rail unit SMTSN 12-T1-W length precisely lengths to the millimetre, here choosable up to 6000mm, with rail in aluminium and shaft in hardened, quality: Cf53 (1.1213) This system you can combined with all open (look the "o" in the name of article) housing units, see categorie: http://lineareasy.com.de/shop/index.php/cat/c12_Gehaeuseeinheiten.html Urgent notes for order: The excat required length of the unit please enter in the bottom field. If you give us no note there, we supply automatically the maximum length of this article. The type SMTSN we deliver assembled to you. Product data unit: Dimensions: Type d A h +/- 0,15 V N1 N2 d1 d2 W (°) E T weight./kg* SMTSN-12 12 40 22 5 8,0 5,0 4,5 4,5 5,8 50 29 75 0,52 *weight in the table it relates to a rail with length 600mm without shaft. depending on the length of the shaft support rail unit, the rail is composed of several individual section T5 min = 20mm the weight of the unit you´ll see down on this side material of shaft support: Aluminium Product data shaft: Material shaft: Cf53 Hardened: 59-65 HRC Rht min.0,6 Grounded Tol. h6 (0-11my) Surface roughness: Ra <= 0,3 Weight (shaft only): 0,89kg/m Straightness:0,2mm/m Predrilled: see the table Chamfer: on both sides of the shaft appr. 1 - 2mm x 30° (depending the diameter of the shaft)

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Shaft support rail unit SMTSN 12-T2-W length precisely lengths to the millimetre, choosable up to 6000mm, with rail in aluminium and shaft in hardened, quality: stainless steel X46Cr13 (1.4034) This system you can combined with all open (look the "o" in the name of article) housing units, see categorie: http://lineareasy.com.de/shop/index.php/cat/c12_Gehaeuseeinheiten.html Urgent notes for order: The excat required length of the unit please enter in the bottom field. If you give us no note there, we supply automatically the maximum length of this article. The type SMTSN we deliver assembled to you. Product data unit: Dimensions: Type d A h +/- 0,15 V N1 N2 d1 d2 W (°) E T weight./kg* SMTSN-12 12 40 22 5 8,0 5,0 4,5 4,5 5,8 50 29 120 0,52 *weight in the table it relates to a rail with length 600mm without shaft. depending on the length of the shaft support rail unit, the rail is composed of several individual section T5 min = 20mm the weight of the unit you´ll see down on this side material of shaft support: Aluminium Product data shaft: Material shaft: stainless steel X46Cr13 Hardened: 52-56 HRC Rht min.0,6 Grounded Tol. h6 (0-11my) Surface roughness: Ra <= 0,3 Weight (shaft only): 0,89kg/m Straightness:0,2mm/m Predrilled: see the table Chamfer: on both sides of the shaft appr. 1 - 2mm x 30° (depending the diameter of the shaft)

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Shaft support rail unit SMTSN 12-T2-WV length precisely lengths to the millimetre, choosable up to 6000mm, with rail in aluminium and shaft in hardened, quality: Cf53-chrome plated (1.1213) This system you can combined with all open (look the "o" in the name of article) housing units, see categorie: http://lineareasy.com.de/shop/index.php/cat/c12_Gehaeuseeinheiten.html Urgent notes for order: The excat required length of the unit please enter in the bottom field. If you give us no note there, we supply automatically the maximum length of this article. The type SMTSN we deliver assembled to you. Product data unit: Dimensions: Type d A h +/- 0,15 V N1 N2 d1 d2 W (°) E T weight./kg* SMTSN-12 12 40 22 5 8,0 5,0 4,5 4,5 5,8 50 29 120 0,52 *weight in the table it relates to a rail with length 600mm without shaft. depending on the length of the shaft support rail unit, the rail is composed of several individual section T5 min = 20mm the weight of the unit you´ll see down on this side material of shaft support: Aluminium Product data shaft: Material shaft: Cf53-chrome plated Chrome layer thickness: ca. 10 my Chrome layer hardness: >= 800HV Hardened: 59-65 HRC Rht min.0,6 Grounded Tol. h7 (0-18my) Surface roughness: Ra <= 0,3 Weight (shaft only): 0,89kg/m Straightness:0,2mm/m Predrilled: see the table Chamfer: on both sides of the shaft appr. 1 - 2mm x 30° (depending the diameter of the shaft)

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Shaft support rail unit SMTSU 12-W length precisely lengths to the millimetre, choosable up to 6000mm, with rail in aluminium and shaft in hardened, quality: Cf53 (1.1213) This system you can combined with all open (look the "o" in the name of article) housing units, see categorie: http://lineareasy.com.de/shop/index.php/cat/c12_Gehaeuseeinheiten.html Urgent notes for order: The excat required length of the unit please enter in the bottom field. If you give us no note there, we supply automatically the maximum length of this article. The type SMTSU will be not mounted !. Product data unit: Dimensions: Type Ød h +/-0,15 H1 A A1 W M Ød1 e T Gew kg SMTSU-12 12 14,5 3 11 6,0 5,4 M4 4,5 15,5 75 0,44 *weight in the table it relates to a rail with length 600mm without shaft. depending on the length of the shaft support rail unit, the rail is composed of several individual section T5 min = 20mm the weight of the unit you´ll see down on this side material of shaft support: Aluminium Product data shaft: Material shaft: Cf53 Hardened: 59-65 HRC Rht min.0,6 Grounded Tol. h6 (0-11my) Surface roughness: Ra <= 0,3 Weight (shaft only): 0,89kg/m Straightness:0,2mm/m Predrilled: see the table Chamfer: on both sides of the shaft appr. 1 - 2mm x 30° (depending the diameter of the shaft)

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Shaft support rail unit SMTSU 12-W length precisely lengths to the millimetre, choosable up to 6000mm, with rail in aluminium and shaft in hardened, quality: stainless steel X46Cr13 (1.4034) This system you can combined with all open (look the "o" in the name of article) housing units, see categorie: http://lineareasy.com.de/shop/index.php/cat/c12_Gehaeuseeinheiten.html Urgent notes for order: The excat required length of the unit please enter in the bottom field. If you give us no note there, we supply automatically the maximum length of this article. The type SMTSU will be not mounted !. Product data unit: Abmessungen: Type Ød h +/-0,15 H1 A A1 W M Ød1 e T Gew./kg* SMTSU-12 12 14,5 3 11 6,0 5,4 M4 4,5 15,5 75 0,44 *weight in the table it relates to a rail with length 600mm without shaft. depending on the length of the shaft support rail unit, the rail is composed of several individual section T5 min = 20mm the weight of the unit you´ll see down on this side material of shaft support: Aluminium Product data shaft: Material shaft: stainless steel X46Cr13 Hardened: 52-56 HRC Rht min.0,6 Grounded Tol. h6 (0-11my) Surface roughness: Ra <= 0,3 Weight (shaft only): 0,89kg/m Straightness:0,2mm/m Predrilled: see the table Chamfer: on both sides of the shaft appr. 1 - 2mm x 30° (depending the diameter of the shaft)

Results for

Aluminum railings - Import exportNumber of results

23 ProductsCountries

Company type