- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- die-casting foundries

Results for

Die-casting foundries - Import export

FONTE GRISE DISTRIBUTION

France

Several moulding sites for the diversity of shapes Traditional: shake/pressure, automated: for small and medium production runs Ultra-automated: DISAMATIC-type vertical parting line moulds, with unrivalled formats and surface finishes: parts weighing up to 200kg per mould with a tooling format of 1200x1050 mm. Manual, on the floor: unit production and production of non-standard formats.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit offers a wide range of tools for the manual and automated finishing of cast workpieces in foundries. These include cutting discs for angle grinders and stationary machines as well as roughing discs in various degrees of hardness. Resin-bonded tools and diamond grinding discs offer maximum service life and precision for the automated machining of grey and nodular cast iron. Tools for all requirements In addition to cutting and grinding discs, the range also includes mounted points and carbide burrs for straight grinders and industrial robots, which are ideal for hard-to-reach areas. A large proportion of the products belong to the PREMIUM segment, which speaks in favour of the high quality of Tyrolit tools. Advantages of the Tyrolit range: . Variety of shapes and dimensions . Long tool life and cutting ability . Consistently high performance . Above-average comfort

Request for a quote

AKROMAK METAL DIŞ TIC. LTD. ŞTI.

Turkey

Our core competence is the export of castings. We are able to choose the most suitable manufacturer for your needs. Not only cheap prices, but also the guarantee of the required quality are taken into account.

Request for a quote

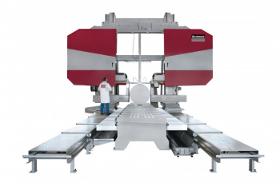

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

EUROPE ZHAOHAN VACUUM PUMP CO., LTD

Hungary

The CL series offers medium capacity ranging from 900 to 5100m³/h, it is widely used in many application including: autoclaves, carburetor testing, chucking, condenser exhausting, container filling, cooking, drying, evisceration, exhausting, extruder venting, fiber setting, filtering, forming, gas stripping, molding, pickup and conveying, priming, slot extraction, and solvent recovery. Different with most India cone pump, we are using castings from best domestic foundries,all castings are provided with related material test report . We offering SS420 shaft for all our cast iron pump, it is more reliable in performance and offer longer using life thanIndiaand original Nash CL liquid ring vacuum pump. To meet client’s different installation requirement, we offer both DIN and ANSI flange connection. All our CL liquid ring vacuum pump is 100% performance tested before shipment.

Request for a quote

BIRMINGHAM INDUSTRIES (UK, INDIA)

United Kingdom

Our A grade maize starch meets the highest standards and is a versatile product that can be applied across a variety of industries such as: •Textiles (sizing, finishing, printing) • Paper and cardboard • Glues and Adhesives • Rubber and foam • Paint fillers and putty • Cosmetics • Detergents • Aluminium and Cast-Iron Foundries • Fireworks • Dry battery cell This multifunctional product can be modified to your needs and our sales team would be more than happy to help you find the starch that fits your industrial requirements.

KUTES METAL

Turkey

-Group 1 Moulding Line : Brand : Georg Fischer Type : Impact Standard IM-S-1 otomatik yatay kalıplama hattı Dimensions : 800 x 600 x 250/250mm Capacity: 120 mold / hour Pooring Unit: Inductotherm Visipour P3 Otomatik Tundish Sand Unit : Georg Fischer Conveyor Systems: Georg Fischer Shakeout: Jöst -Group 2 Moulding Line : Brand : HWS (Heinrich Wagner Sinto) Model : Seiatsu EFA-SD otomatik yatay kalıplama hattı Dimensions : 900 x 700 x 300/300mm Capacity: 120 mold / hour Pooring Unit: HWS Otomatik döküm potası Sand Mixer: Eirich RV24 - 3000 Lt - 78 m3 mold sand / hour Sand Control Unit: QualiMaster AT1 Conveyor Systems: VHV Belt Conveyor, Jöst Vibra Conveyor Stakout : Jöst Cooling Tunnel : Jöst

Request for a quote

YOUNG FOUNDRY - ANATOLIA CASTING

Turkey

Casting iron products, foundry, manhole, gratings, ductile cast iron tree gratings, cast iron castings, contract manufacturing of cast iron casting, outsource for cast iron casting, subcontractor for cast iron casting, drain covers, Casting Channel, polymer Channel, Ductile Iron U Channel Grid for Rainwater System, Ductile Iron Gully Grating, Ductile Iron Channel Grating Water Grates, Cast Iron Sewer Grating for Sewerage System, Ductile Iron Drain Grid, Ductile iron gratings, Ductile Iron Grate and Frame, Cast Iron Drainage Grid EN124, Rain grate, Ductile Iron Locking Grid, sewer cover, DCI Manhole Cover, Ductile Iron Manhole Cover,Square Manhole Cover,Cast Iron Manhole Cover En124 F900 E600 D400 C250 B125 A15, Access Covers, Gully Grates, Kerb Drainage, Surface Boxes, molding etc hs code 732599

Request for a quote

MVA D.O.O.

Slovenia

High pressure die casting with various aluminum alloys

Request for a quote

POBJEDA DD TESANJ

Bosnia and Herzegovina

Pobjeda's subsidiary – Foundry Turbe manufactures grey cast and nodular cast products in weights of 0,5 to 300 kg, housings, covers and impellers used in oil and water pumps, as well as covers with frame, sewer and drain grids, garden program (benches, tables, poles), brake pedals for trains etc. Production is based on the manufacturing of castings via machine and manual molding. Foundry’s annual capacity is up to 2.000 t, and the production of casts is done in electro-induction furnaces.

Request for a quote

ALUSELL

Turkey

Send us your sketch/request and we will make an offer within 24 hours.

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

Netherlands

Material: custom size: according to drawings Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

ABF LT

Lithuania

We are able to offer aluminium die casting services in Lithuania using automated die casting machines from 350 to 850 tons. Supported by CNC milling and rotary transfer machining, we can provide semi finished product for your company's' project.

Request for a quote

INTER INSTRUMET, PE

Ukraine

Production of castings by the LAP method from aluminum, zinc and other low-melting alloys on machines with a cold horizontal pressing chamber with locking force from 250 to 420 t / s, weighing from 0.050 kg to 6.0 kg. Production of castings by casting into metal reusable molds (chill molds) of aluminum alloys, on chill machines with manual and hydraulic drive, the mass of castings from 0.050 kg to 6.0 kg.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

Netherlands

Aluminum Die Castings ADC12 A356 for engine 1, Die Casting, Gravity Casting, Sand Casting 2, Materials: Aluminum alloy, zinc alloy, bronze. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Die-casting foundries - Import exportNumber of results

18 ProductsCountries

Category

- Foundries, aluminium (5)

- Moulds, foundry (3)

- Casting, steel (2)

- Foundries - copper, bronze and brass (2)

- Iron and steel industry and foundries - machinery and installations (2)

- Articles for sculpture (1)

- Cast iron items (1)

- Die casting moulds (1)

- Portable power tools (1)

- Sawing machine tools (1)

- Starch, industrial (1)

- Vacuum pumps (1)