- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- degassing

Results for

Degassing - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

We use this vacuum degasser to clean all kinds of products before do the coating. This degas chamber is venting the gas,air and other impurities through putting in the heated N2. This vacuum degasser will greatly shorten the vacuum time, reduce the oxygen corrosion, protect the machine and prolong the life time of the equipment. It enhances the adhesion of the film in the products.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

AVUSE-1 for degassing under pressure, AVUSE-3 for degassing, high flow rate air inlet and outlet. Simple but studied design – To reach the best performances with optimized components. Ventilation area protected – From splashes and clogging thanks to a specific deflector design, ensuring a long term operation. Polymeric high-quality material. Easy maintenance – Thanks to quick removal of the clamps and drainage cock.

Request for a quote

ENKI WATER TREATMENT TECH. LTD

Turkey

A "CO2 degasser" (degassifier) is a relatively simple water treatment device. Incoming water is sprayed into a tower filled with packing material. The drops of water that flow down through the tower strike the packing material and form a thin film on the packing material surface, encouraging the release of excess carbon dioxide. A centrifugal fan creates an updraft of air through the tower to carry away the released carbon dioxide gas. The carbon dioxide gas exits through a vent at the top of the unit.

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our duct systems for battery ventilation feature highly flexible sections combined with high stiffness in the cuff section. Connecting elements and matched accessories allow for easy assembly and disassembly. Available materials/maximum operating temperature: PP 100°C PA6 120°C PA12 120 Our corrugated tubes with integrated connecting geometries (bayonet lock) are made to customers specifications to guarantee reliable connections and to ventilate or drain duct systems. This saves weight and reduces the risk of leakage. The snap-in geometry allows for time-saving and user-friendly assembly and disassembly. Of course we offer a wide range of accessories and nominal sizes. Available materials/maximum operating temperature: PP 100°C PA6 100°C PA12 120°C

Request for a quote

ATN WASSERAUFBEREITUNG GMBH

Germany

A third category of membranes is used for degassing liquids. When applying a vacuum to one side of the membrane, the liquid itself is not permeable and there is no loss. One typical application is removing dissolved oxygen from brewing water in order to avoid any oxidation processes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GLOBECORE

Ukraine

This GlobeCore mobile oil processing unit is designed for degassing, removal of solids and heating of oil for power transformers with voltage up to 1,150 kV. The unit can be used to: (1) heat electrical systems that contain insulating oil with hot oil; (2) for vacuum drying of transformers and (3) for vacuumizing. The unit is best suited to facilities that install, repair and service oil filled electric power transformers and other oil filled electrical equipment. The unit is not certified for use in and around explosive gases, toxic gases or other aggressive environments. When indoors or other enclosed spaces, exhaust gases must be vented to the outside through hoses or pipelines. no need to use adsorbents to dehydrate transformer oil; operation of equipment causes no air pollution or waste requiring storage and disposal; easy to operate and maintain; maximum oil specifications even after one treatment cycle; low power consumption; low noise level;

Request for a quote

GLOBECORE

Ukraine

GlobeCore manufactures oil regeneration systems for both transformer manufacturers and for transformer service providers. GlobeCore units are loaded with a sorbent that captures all oil decomposition products. GlobeCore regeneration systems can use the same sorbent for up to 3 years before the first replacement. No more need for consumables and costly labor related to replacement of exhausted sorbent on the job site. Regeneration systems can be combined with degassing units or can be purchased as stand-alone systems. GlobeCore regeneration systems can be used in combination with your existing degassing or drying unit. Each GlobeCore unit can be customized and includes a number of options: An extra vacuum pump assembly for transformer vacuuming Mounted on a trailer or a semi-trailer Inlet and/or outlet moisture meters for the oil stream Remote control and process monitoring via smartphone or PC Climate Controlled Operator work room.

Request for a quote

INNOCAP AGRO SOLUTIONS PLASTIC INDUSTRIAL

Turkey

SK50 TAMPER EVIDENT CAPS WITH F15 VENT AND F17 VENT

Request for a quote

INNOCAP AGRO SOLUTIONS PLASTIC INDUSTRIAL

Turkey

SK50 ALUMINIUM FOIL CAP WITH ALUMINIUM FOIL VENT

Request for a quote

INNOCAP AGRO SOLUTIONS PLASTIC INDUSTRIAL

Turkey

10 LITER JERRYCAN AXOR TYPE SK63 TAMPER EVIDENT CAP

Request for a quote

STL SYSTEMS AG

Switzerland

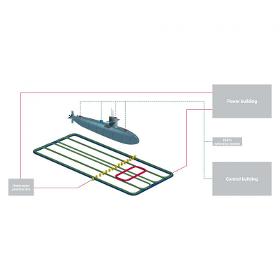

The ODMR (Overrun Deperming and Measurement Range System) is a system dedicated to reduce the magnetic signature of ferromagnetic surface vessels and submarines. It allows a magnetic treatment to control the permanent magnetic signature of the ships in such a way that the ships magnetic signature is minimized. The deperming efficiency depends on the individual class of vessel undergoing treatment, the magnetic behaviour of the steel used, the building process and the magnetic history of the vessel and the operational area with respect to its vertical magnetic field component. The fields of the ODMR are sufficient large to allow a deperming and ranging for all missions required. The ODMR can be designed for all kind of surface vessels and submarines independing of the displacement with maximum length of upto 250 m length, with the dedicated beam depth.

Request for a quoteResults for

Degassing - Import exportNumber of results

12 ProductsCountries

Company type

Category

- Bottles and jars, plastic (3)

- Oil filters (2)

- Chemical industry - machinery and equipment (1)

- Coating machinery (1)

- Custom packaging (1)

- Electrical components and parts (1)

- Hoses, pipes and tubes - plastic (1)

- Water - production and distribution (1)

- Water treatment, industrial - systems and equipment (1)