- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- deep drawing moulds

Results for

Deep drawing moulds - Import export

PRESSTECK S.P.A.

Germany

Support sleeves for reinforcing plastic components. Made of stainless steel with customised design. The bushings can be produced not only round but also oval as a deep-drawn part.

Request for a quote

PRESSTECK S.P.A.

Germany

Deep drawn cylindrical battery housings made of nickel plated steel Various standard sizes of cylindrical battery housings for edrive applications like 21700, 46800

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm. Pharmaceuticals and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

PRESSTECK S.P.A.

Germany

You don't need deep-drawn individual parts, but complex assemblies already assembled? We are your experts for that! First we analyse your requirements for new potentials. Combined with innovative thinking and agile processes, we then design smart solutions with you to manufacture your desired assemblies. Depending on your requirements, we develop decoupled, partially or fully interlinked assembly processes using high-performance systems and state-of-the-art equipment. We reliably ensure your quality requirements with integrated and individual testing measures.

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm.Pharmaceutical and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

PRESSTECK S.P.A.

Germany

Pressteck is one of the world's leading specialists for deep-drawn individual parts on transfer presses and their processing into assemblies. In this non-cutting tension-pressure process, we produce hollow parts from a metal strip in several stages, which can be aluminium, stainless steel, copper or brass, among others. Compared to other processes, deep drawing has decisive advantages: Material consumption and production costs are lower, and at the same time the strength of the components is higher. We are highly innovative and optimise deep drawing technology beyond what is currently possible. We manufacture your individual component from coiled sheet metal and master demanding geometries and high degrees of forming.

Request for a quote

PRESSTECK S.P.A.

Germany

Thermostatic valves - i.e. the temperature controls on the heating system - are found in just about every home. In the head of a thermostatic valve there is a metal bellows, a corrugated tube that expands according to the room air temperature. For these metal bellows, the manufacturer needed deep-drawn, very long and thin-walled sleeves. The challenge: the sleeves must be matched to the customer's downstream process under very tight tolerance specifications. Why? Because the sleeves cannot be further processed if the geometries vary. Absolute precision is therefore required. We can offer absolute precision. The customer commissioned us with the production of the sleeves. On the one hand, because we fulfil the special deep-drawing requirements. On the other hand, because we can offer an associated, targeted heat treatment for material stress relief in-house.

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

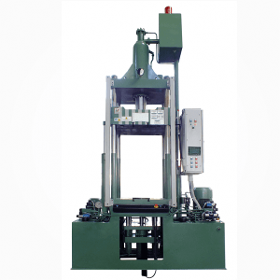

OZKOC HYDRAULIC MACHINE CO.

Turkey

Hydraulic press for deep drawing, forging, forming and cutting process

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

double action conventional hydraulic press (top effect)

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

double action conventional hydraulic press (top effect)

Request for a quote

OCV ITALIA

Italy

M720 chopped strand mat represents a compelling solution for deep draw and complex molding processes with highly filled resin systems. EASY HANDLING AND MOLDABILITY Optimized bonding and chop length mix bring high conformability and easy hand tearing for tailored shapes. PROCESS EFFICIENCY Fast wetting and quick air release maximize molding productivity. Excellent weight uniformity helps laminate consistent thickness. ENHANCED SERVICE LIFE Compared to standard Eglass, Advantex® glass helps with enhanced service life in applications facing corrosion. M720 mat is designed for hand layup process with polyester, vinyl ester resin systems.

Request for a quote

EXCOR KORROSIONSSCHUTZ-TECHNOLOGIEN UND -PRODUKTE GMBH

Germany

EXCOR VALENO Trays and Containers are made of hard plastics based on polyethylene and polypropylene and manufactured using deep-drawing or injection moulding techniques. The durability of these containers makes them the ideal choice for multiple uses, or may with narrower walls be employed as single-use packaging. The work pieces or small loads to be transported fit snugly into the containers. No additional VCI diffusers are needed since the plastic is impregnated with VCI substances. These two combined properties markedly simplify every kind of automated transport and storage process. Provided the instructions for use are followed EXCOR VALENO Trays and Containers will offer corrosion protection for up to five years.

Request for a quote

HIDROKAR HYDRAULIC PRESS MACHINES INDUSTRY

Turkey

Our manufacturing style is user-oriented, and we manufacture in different features, heights, widths,tonnages through our customers' desires and options. The machines and the matarials used in manufacturing process are durable , you can utilize for many years.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

In case of need for high quantity production with multi deep drawing operations, Ozkoc offers 2 different solutions. Hydraulic Transfer Press Hydraulic Triple Action Press Advantage of triple action to double action press is on one mold and one hydraulic press, material can be deep drawn 2 times in a row without any additional workload. Its most suitable for where height is much bigger than material diameter such as fire extinguishers, car-truck filters and alike.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

For the deep drawing parts which symetrical and deeper than 100 mm, forget about conventional presses. Ozkoc Bottom effective deep drawing presses can provide you faster production with 30% less energy consumption comparing to conventional hydraulic presses. Please dont hesitate to contact our technical speacialist to suggest you the best solution for your production.

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Deep Drawing is the most common tecnique for forming either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. The material is held tight between the ram and the blank holder to avoid the formation of wrinkles while the force of the ram pushes the die down to wrap it around the punch. Conventional Deep Drawing Press find use in metal forming, especially in automotive, kitchenware, defense, security and many other sectors. This is the most common tecnique for producing either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. In need of pressing speed or cushion adjustment for better product surface , Ozkoc Hydraulic presses have option for speed settings on touch screen via proportional valves. The press automation is PLC supported, and programmed with Siemens S7.1200 software. The press is two push buttons controlled

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Deep drawing moulds - Import exportNumber of results

17 ProductsCountries

Company type