- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dead volume

Results for

Dead volume - Import export

STAIGER

Germany

Miniaturized media-separated 2-way valve in the 8 mm series to control challenging media. This compact, media-separated valve is suitable for precise dosing of neutral and aggressive gases and liquids. Due to the relatively simple design, the valve can be adapted to specific customer requirements without much effort. For example, connection geometry, sealing material and rated voltage can be easily adjusted.

Request for a quote

EM-TECHNIK GMBH

Germany

The flexible tube for the connector 1D is first thermally widened and then pushed on the integrated connecting sleeve. The tube is secured in place by means of a knurled nut acting on the flexible tube. Thanks to the form-fit connection between the connecting sleeve and flexible tube, the connector has no dead volume.

Request for a quote

KELLER PRESSURE

Switzerland

This high-pressure pump generates pressures of up to 700 bar with ease, with fine control for precise adjustment. It is perfect for testing manometers and pressure transmitters. The pump must be filled with 100 cm3 of hydraulic oil or water and can therefore fill up even relatively large dead volumes. An additional manometer (not supplied) is needed for reference measurement of the configured pressure. KELLER recommends manometers in the LEX1 series with a suitable pressure range.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoTec Hygienic Dispenser is available in 3 different sizes, allowing for volumes of 0.35ml up to 5.1ml per revolution. The smallest of dosage volumes can be perfectly dosed with a deviation of only +/- 1%. In addition to FDA-compliant components, and an EHEDG-compliant hygienic design, is the possibility of automatic cleaning via additional connection outlets. The cleaning medium is applied via the outlet in order to carry out automatic rinsing. Alternatively, the new dispensers can be disassembled quickly and cleaned manually. As in all dosing systems from ViscoTec, the VHD uses the proven endless piston technology based on the use of eccentric screw technology. For the VHD, many characteristics have been optimized and specially enhanced for use in the food and cosmetics branch. Among other things, the interior of the dispenser has been analysed and redesigned: the goal being to avoid dead volume and thus prevent contamination through harmful micro-organisms.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

With its rugged housing and a stainless steel sensor element, the transducer is particularly robust and ideally suited to the harshest environments. This also means that the sensor can be installed anywhere with no effect on the measurement signal. The built-in instrumentation amplifier converts the sensor signals into noise-immune voltage signals or current signals that can be transmitted over relatively long distances. For high viscose materials, a front-level membrane M12 x 1 is available, and with this disruptive dead volumes can be expelled. The sensor has a small protected hole on the rear to allow measurement of atmospheric pressure (measurement type relative). For the absolute measurement option, the applied pressure is measured with respect to an enclosed vacuum. As an electrical connection, a DIN 43650A valve connector or an M12 x 1, 4-pin connection is available.

Request for a quote

EM-TECHNIK GMBH

Germany

For the 2N pipe connector, the pipe is placed against the inner edge of the connector and a sealing ring seals off the connection. A cutting ring wedges into the flexible tube or pipe as far as the knurled nut is screwed onto the connector body, thereby fixing the connection in place. This creates a friction-locked and tight pipe connection that can be released at any time, that eliminates dead volume in the design concept and also has no effect on the flow. The inside diameter of the connector does not correspond to the inside diameter of the pipe.

Request for a quote

EM-TECHNIK GMBH

Germany

The firm flexible tube or plastic pipe is pushed onto the integrated connecting sleeve of the 1C connector. The sealing ring forms a tightness for the connection, while it is secured in place by a cutting ring. Due to the knurled nut, this also affects the flexible tube. The cutting ring wedges into the flexible tube or pipe as far as the knurled nut is screwed onto the connector body. A shear force is applied here that intensifies the contact pressure. This creates a friction-locked and tight connection that can be released at any time and minimises the dead volume.

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

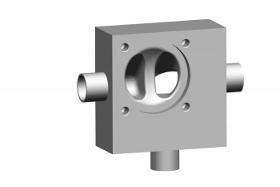

SISTO-CM210 ● Multi-port valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Butt weld ends or clamped connection ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN6–DN100 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free ●Compact, space-saving design

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

SISTO-C ● Soft-seated shut-off valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Body designs: 2-way valve body, T-pattern, Y-pattern, tank or multi-port valves ● Butt weld ends or clamped connection ● Drain angle indicated by laser marking ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN 6 – DN 200 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

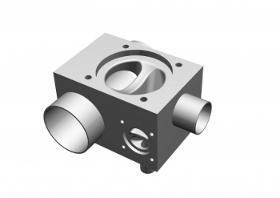

SISTO-CM508 ● Multi-port valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Butt weld ends or clamped connection ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN6–DN100 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free ●Compact, space-saving design

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

SISTO-C ● Soft-seated shut-off valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Body designs: 2-way valve body, T-pattern, tank or multi-port valves ● Butt weld ends or clamped connection ● Drain angle indicated by laser marking ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN 6 – DN 200 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

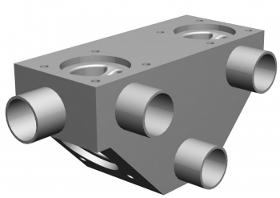

SISTO-CM214 ● Multi-port valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Butt weld ends or clamped connection ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN6–DN100 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free ●Compact, space-saving design

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

SISTO-CM1200 ● Multi-port valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Butt weld ends or clamped connection ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN6–DN100 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free ●Compact, space-saving design

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

SISTO-CM409 ● Multi-port valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Butt weld ends or clamped connection ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN6–DN100 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free ●Compact, space-saving design

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

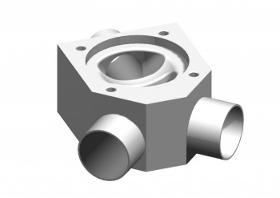

SISTO-CY ● Soft-seated shut-off valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Body designs: 2-way valve body, T-pattern, tank or multi-port valves ● Butt weld ends or clamped connection ● Drain angle indicated by laser marking ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN 6 – DN 100 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

SISTO-CT ● Soft-seated shut-off valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Body designs: 2-way valve body, T-pattern, tank or multi-port valves ● Butt weld ends or clamped connection ● Drain angle indicated by laser marking ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN6 – DN150 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free

Request for a quote

SISTO ARMATUREN S.A.

Luxembourg

SISTO-CBAV ● tank valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Body designs: 2-way valve body, T-pattern, tank, multi-port valves ● Butt weld ends or clamped connection ● Drain angle indicated by laser marking ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN6–DN150 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free ●Compact, space-saving design

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SISTO ARMATUREN S.A.

Luxembourg

SISTO-CM700 ● Multi-port valve ● Unique design with enclosed diaphragm ● Diaphragm with spiral support starting with size MD65 ● With manual or pneumatic actuator ● Shut-off and sealing to atmosphere by diaphragm, therefore two components in contact with the fluid handled only: body and diaphragm ● Butt weld ends or clamped connection ● Body materials: forged stainless steel and other alloy materials ● Diaphragm materials: EPDM, TFM/EPDM bonded, TFM/EPDM 2-piece ● Available nominal diameters: DN6–DN100 ● Operating temperature: – 20°C to + 160°C ● Permissible operating pressure: vacuum up to 16 barg/ optional 20 barg Benefits: ● Suitable for applications up to a line pressure of 16 barg ● Increased operating reliability ● Self-draining ● No dead volume ● No contamination of fluid handled ● Suitable for CIP/SIP ● Maintenance-free ●Compact, space-saving design

Request for a quote

PHENOMENEX LTD.

Germany

The SecurityLINK UHPLC fingertight fitting system simplifies your system and column connections and provides consistent performance with torque limiting technology that prevents column damaging overtightening. Try SecurityLINK UHPLC fittings on your system today: - No tools required for quick and easy installation - Fitting self-adjusts at column inlet to ensure zero dead volume for better chromatographic results - Torque limiting technology prevents system and column port damage UHPLC and HPLC compatibility: pressure rated to 19,000 psi (1,310 bar)

Request for a quote

PHENOMENEX LTD.

Germany

- Extends UHPLC, core-shell, and sub-2 μm column lifetime - Fits virtually all manufacturers’ columns 2.1 to 4.6 mm ID - Pressure rated to 20,000 psi (1,378 bar) - Simple to use With SecurityGuard ULTRA, contaminants and micro particulates are trapped in the guard cartridge, instead of your expensive column. The extremely low dead volume (<0.3 µL) of this unique guard design minimizes sample peak dispersion to maintain column performance without altering your chromatography results.

Request for a quote

NORMIT

Slovakia

Tilting pan with indirect heating and integrated stirrer is designed for frying, steaming, cooking vegetables, fish, meat, sauces, pasta with constant stirring, eliminating the risk of burning or uneven heat treatment. Processes: •Stewing •Cooking •Evaporation •Frying •Deep frying Advantages: • Equipped with a duplicator and electric heating elements. • Fast heating and high thermal efficiency. • Reinforced stirrer with Teflon scraper, which in continuous mode cleans not only the entire bottom, but also the walls of the pan, ensuring a perfect result. • Tilt ensures complete unloading of the working container. • Made of high-quality food-grade stainless steel AISI304 or AISI316L. • Easily sanitizable • No dead zones. Technical specification: Working volume up to 130l Recommended Termooil heating Frying temperature up to 160 C Stirring device: yes Product unloading type: electric driven tilt system Dimensions (LxHxW): 1800x1900x1400 mm Weight: 350 kg

Request for a quote

CLIPPARD EUROPE SA

Belgium

The Clippard NIV Series Media Isolation Valve is a solenoid-operated device that uses a flexible diaphragm to isolate the actuation mechanism from the fluid path. Media isolation valves are commonly used for a wide variety of applications, including those that require precise, repeatable dispensing of media for analytical instrumentation. All wetted areas of the valve are PTFE, making this series ideal for use with corrosive media. Features: • Low power consumption • Compact, lightweight design • Bidirectional • Zero dead volume • All wetted areas PTFE • Ideal for use with corrosive media • High cycle life • Fast response time • CE, RoHS compliant • ISO 9001:2008 • Proudly made in the U.S.A.

Request for a quote

CLIPPARD EUROPE SA

Belgium

These direct actuating valves offer an extremely fast response time for accurate dosing of minute volumes with the same long life you expect from the original Clippard EV line of electronic valves, now in a 7 mm cartridge package. Due to very low moving weights, they are extremely quiet and emit very low vibration. Subminiature size and low energy consumption make them ideal for transportable and mobile systems, among others. The SV series valves can be fully customized according to the user's unique requirements. Consult Clippard with your specific application. Features: •1,000,000,000+ cycle life • Extremely small dead volume • Low vibration and noise • Fast response time • Low energy consumption • 100% tested The same long life you depend on from Clippard's original EV line of electronic valves!

Request for a quote

CLIPPARD EUROPE SA

Belgium

The Clippard NPV Series Pinch Valve is a solenoid-operated device that is designed to open and close tubes for controlling flow of liquids and gases. Other valve types have internal passages that may cause small amounts of fluid to remain in the valve. Pinch valves have no areas or dead volume where fluid can become trapped. Only the inside of the tubing contacts the fluid. Energizing the solenoid retracts or attracts the plunger, which opens or closes the tube. De-energizing the solenoid will allow the plunger to return to its original state. Features: • Small, compact design • Hygienic and easy to clean (replace tubes) • Low power consumption • High cycle life • Can handle whole blood and particulate matter • Unobstructed flow path • Each valve comes with 12" of silicone tubing • Variety of tubing sizes available • Tubing is easily replaceable Available in 2-Way Normally-Open or Normally- Closed or 3-Way ( one tube N.O. and one tube N.C.) configurations

Request for a quote

ILS INNOVATIVE LABOR SYSTEME GMBH

Germany

Glass Barrel: Borosilicate 3.3 Precision: < ±1 % of the volume Main Use: - sample dosage for gas chromatography - dosage of small amounts of liquids - for Thin Layer Chromatography (TLC) Removable Needles (RN) autoclavable stainless steel= ss* plunger runs inside the needle (plunger in needle) Needle Tip Tip Style a b c d (RN) (RN) (RN) (RN) Length 70mm 70mm 70mm 70mm Plunger Part Part Part Part Volume Tip O.D.(Gauge) No. No. No. No. 0.5µl ss* 0.47(26s) 2200051 2200058 - - 0.5µl ss* 0.64(23) 2200062 2200056 2200061 - 1µl ss* 0.47(26s) 2200101 2200102 - 2200103 1µl ss* 0.64(23) - - 2200113 2200303 2µl ss* 0.72(22s) 2200201 2200202 - - 5µl ss* 0.55(24) 2200301 2200302 - 2200203 10µl ss* 0.72(22s) 2200401 2200402 - 2200403 25µl ss* 1.10(19) 2200501 2200502 - 2200503

ILS INNOVATIVE LABOR SYSTEME GMBH

Germany

0.5µl - 25µl - Zero dead volume - Positive displacement - Sample contained only in the needle - Removable syringe parts Zero Dead Volume Syringes plunger runs inside the needle

ILS INNOVATIVE LABOR SYSTEME GMBH

Germany

Series H - PTFE Seal for dispensing Gas and Liquids gas tight plunger replaceable Series SH - Extended Handle / PTFE Seal for gas chromatography and HPLC valves prevents heat transfer from hand to content protects plunger from bending Series G - Static PTFE Seal Topping the Glass Barrel for gas chromatography HPLC valves dosage under counter-pressure Series P - Adjustable PTFE Seal for gas chromatography and HPLC valves dosage under pressure regulation of seal pressure by screws Headspace Analysis gas tight plunger replacable Peek Tubing Connector direct connection reduced dead volume totally inert, no metal contact Adjustable Internal Stopper excellent for routine dosages internal index stop is adjustable to any volume for faster work and better reproducibility

ILS INNOVATIVE LABOR SYSTEME GMBH

Germany

Glass Barrel: Borosilicate 3.3 Precision: < ±1 % of the volume Zero dead volume(plunger in needle)= T Removable Needle (RN) autoclavable stainless steel= ss* Needle Tip LC 12/20/32(Siemens) Tip Style c (RN) Length 70mm Plunger Part Volume Series Tip O.D.(Gauge) No. 1µl T ss* 0.64(23) 2200115 PE-1000 ,RA-342(Nippon Corp.) Tip Style d (FN) Length 55mm Plunger Part Volume Series Tip O.D(Gauge) No. 50µl A PTFE-black 0.72(G22) 2600642 100µl A PTFE-black 0.72(G22) 2600742

ILS INNOVATIVE LABOR SYSTEME GMBH

Germany

Glass Barrel: Borosilicate 3.3 Precision: < ±1 % of the volume Advantage: - direct connection - reduced dead volume - totally inert, no metal contact - fits any tube from 0.8 to 3.2 mm Ø - chemically resistant Plunger Part Volume Series Tip Connector No. 10µl H PTFE M6 2624414 25µl H PTFE M6 2624514 50µl H PTFE M6 2624614 100µl H PTFE M6 2624714 250µl H PTFE M6 2624814 500µl H PTFE M6 2624914 1.0ml H PTFE M6 2624015 2.5ml H PTFE M6 2624035 5.0ml H PTFE M6 2624055 10.0ml H PTFE M6 2624075 25.0ml H PTFE M6 2624095 50.0ml H PTFE M6 2624105 100.0ml H PTFE M6 2624116 10µl H PTFE 1/4"x 28 2624415 25µl H PTFE 1/4"x 28 2624515 50µl H PTFE 1/4"x 28 2624615 100µl H PTFE 1/4"x 28 2624715 250µl H PTFE 1/4"x 28 2624815 500µl H PTFE 1/4"x 28 2624915 1.0ml H PTFE 1/4"x 28 2624016 2.5ml H PTFE 1/4"x 28 2624036 5.0ml H PTFE 1/4"x 28 2624056 10.0ml H PTFE 1/4"x 28 2624076 25.0ml H PTFE 1/4"x 28 2624096 50.0ml H PTFE 1/4"x 28 2624106 100.0ml H PTFE 1/4"x 28 2624115

Results for

Dead volume - Import exportNumber of results

32 ProductsCompany type