- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cylinder of motor

Results for

Cylinder of motor - Import export

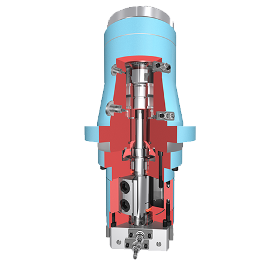

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

1. NBR shaft seals on hardened cylinder barrels Drum motors axles are usually manufactured from ST37. Commercially available seals rotate directly on the axles. The result, at some point in time, is grooves on the axle. In addition of course oil leaks. This is not the case with the FTK Förderband Technik Kilian pulley motors all drum motors are equipped with hardened and polished cylinder barrels made of stainless steel 316. 2. Oil loss is not a problem for us! Oil change after 50,000 hours of work. Today, for reasons of cost, fewer and fewer users concern themselves with plant maintenance. The maintenance of complex plants is mainly carried out by outside specialists. Simple prefabricated parts, however, are usually used till worn out. This is also the case with drum motors. We have made allowance for this behaviour. The FTK Förderband Technik Kilian drum motors only require an oil change after 50,000 hours of work. In the case of operation with 3 shifts for example

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

The completely equipped electrical cylinder unit includes the motor transmission unit, along with the motor brake, two-channel Hall-IC sensor and two end-limit switches. All connection lines run directly out of the unit to make configuration and initial start-up easier, particularly for PLC operation. The fixation of the electric cylinder connections is compatible with commercial pneumatic and hydraulic cylinders.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-EVF economy automatic horizontal piston filler is equipment with 2 or 4 filling heads,the driven system can be air cylinder or a servo motor. Feature 1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machi machines are made of high-quality stainless steel, making them durable and easy to clean.

Request for a quote

PACA GMBH

Germany

A special cleaner for throttles in fuel-injection systems and carburettors. When oil encrustations build up, throttles become misaligned. This is caused by the evaporation of oil and fuel, and can cause incorrect exhaust emissions to develop. Cleaning with Blast it! restores the default position of the throttles and gives you optimal exhaust control. Fields of application Suitable for throttles, intake manifolds and exhaust gas recycling ventilators of all petrol and diesel engines. Usage Remove the throttle, insert the extension tube into Blast it!’s spray nozzle and shake the can well. Then spray onto dirty areas. Allow about 5 minutes for it to take effect and then wash the residue out by spraying again. If necessary, wipe over with a cloth, then re-attach the throttle. In the case of 6-cylinder motors, firstly scratch out the incrustation on the intake manifold with a screwdriver, then clean with Blast it!. Batch quantity/Packaging units Batch quantity: 200ml spray...

Request for a quote

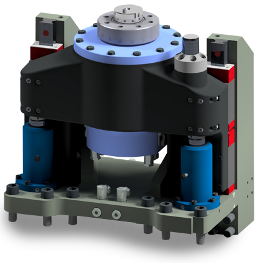

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

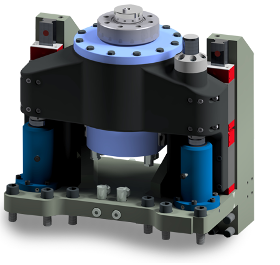

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

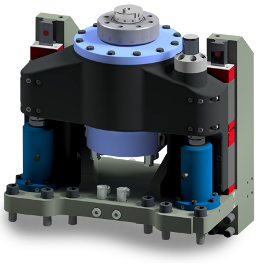

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

AIS HENSCH AUTOMATION-INDUSTRY- SOLUTIONS INH. IGOR HENSCH

Germany

Industrial hydraulics are an essential part of numerous industrial applications and play a crucial role in controlling machines and systems. At AIS Hensch Automation-Industry-Solution, we offer a comprehensive selection of high-quality industrial hydraulic components and systems designed for reliability, efficiency and performance. Precise Control and Performance: Our industrial hydraulic solutions provide precise control and performance for various applications, be it manufacturing, mining, construction or other industrial areas. By using high-quality components and state-of-the-art technologies, we ensure reliable and efficient performance. Versatility and adaptability: Our range includes a wide range of industrial hydraulic components, including hydraulic cylinders, valves, pumps, motors, hoses and much more. These components are suitable for a wide variety of applications and can be flexibly adapted to the specific requirements of our customers.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Micro Cylinder with only 14 mm Cross-section The ultra-compact RCD micro cylinder is a rod type with a length of only 52 to 72 mm and a width of only 12 mm. The motor-driven micro cylinder is designed for applications with low load and power requirements. It can be used for short strokes, press mounting, lifting and lowering and many other applications. The micro linear cylinder with 24 VDC miniature motor for a maximum payload of 0.7 kg is available for stroke lengths of 10, 20 and 30 mm. The small 2.5 W motor has a rated thrust of 4.2 N and a speed of up to 300 mm/s at an acceleration of up to 9.81 m/s.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

EleCylinder are electric cylinders with motor, encoder and integrated controller. These energy-saving actuators are extremely easy to use and operation via data input requires no complicated programming. Start and end points can be set to any position. Due to the high-speed movements, EleCylinders are ideally suited for short cycle times. Unlike pneumatic cylinders, they can also perform slow uniform speeds over the entire stroke. Even gentle starting or braking are no longer a problem. EleCylinder are repairable easily and have only a few maintenance parts.

Request for a quote

TITAN MACHINERY

United Kingdom

Hydraulic station manufacturing refers to the process of designing, assembling, and producing hydraulic power units or stations. These units are essential components of hydraulic systems used in various industrial applications, including manufacturing, construction, agriculture, and more. Hydraulic stations provide the necessary power and pressure to drive hydraulic machinery, such as cylinders, motors, and valves. The manufacturing process of hydraulic stations involves several key steps: Design and Engineering: The process begins with the design and engineering of the hydraulic station. This includes specifying the required flow rate, pressure, and functionality based on the application's needs. Engineers create detailed schematics and plans for the hydraulic station. Component Selection: Manufacturers carefully select hydraulic components such as pumps, motors, reservoirs, valves, filters, and hoses based on the system's specifications. The chosen components should be durable.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Overview of the main motor grab features for which we offer spare parts: Grab shells All bearings Hydraulic cylinders Control blocks Hydraulic pumps Motors Suspension

Request for a quote

ROTAKEM

Turkey

Technicial Specifications 1. Origin: Italy 2. Revision year: 2020 3.Machine cylinder quantity: 4 Pieces 4. Cylinder dimensions: 335x1000 mm 5. Bearings: Bronze 6.Cylinder on / off: Manual 7. Motor power: 45 kW 8.Cooling system: Watering, cooling from the core 9. Engine-gearbox transmission type: Direct coupled 10. Transmission between shaft transmission type: Flywheel gear 11. Arrangement of mills: L-type 12. Friction ratio: 1: 1: 1 13. Optional: - motor driver - Rubber feeding unit - Cloth feeding unit - Hooded cooler - Winder unit - Packaged nylon coating unit

Request for a quote

NORMIT

Slovakia

Drum coater provides easy operation and coating for snack. It’s used for seasoning, salting, adding sugar, adding various ingredients (cinnamon, vanilla, spice ...). Adjustable tilt frame assembly and design exposes each piece of product to the application of liquid and dry coatings. Depending on the application, the dosing of liquids may be through a dosing, perforated pipe and pump or hopper and conveyor system for dry materials. Depending on additional components, the system may be cyclical or continuous. Coating Drum Applications: •Different types of nuts •Chips •Pasta •Cereals •Meat Advantages •AISI 304 stainless steel cylinder. •Motor assembly with variable speed controller. •Variable tilt, stainless steel frame assembly. •Control panel. •Portable casters with brake assembly. •Equipped with paddles for even sprinkling •Drum rotation speed adjustment included •Adjusting the performance of the inclined installation •Possibility to change the height of the supporti

Request for a quoteResults for

Cylinder of motor - Import exportNumber of results

33 ProductsCompany type

Category

- Electric motors and parts (19)

- Automation - systems and equipment (2)

- Hydraulic equipment (2)

- Bottling and filling - machinery and equipment (1)

- Bulldozers and graders (1)

- Construction - Machines & Equipment (1)

- Construction machinery (1)

- Cylinders, pneumatic (1)

- Forming, rubber - machinery (1)

- Industrial sheet metal work (1)

- Mixers and grinders for the food processing industry (1)

- Plastic packaging (1)

- Pumps (1)