- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cyclone separators

Results for

Cyclone separators - Import export

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

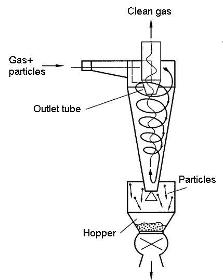

Centrifugal force separator for powder recovery. Cyclone separator A cyclone is a centrifugal force separator and essentially consists of three parts: The intake cylinder, the cone and the immersion tube. In the intake cylinder, the air/particle mixture is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air current and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube.

Request for a quote

SUVIS GMBH

Germany

The gas cyclone belongs to the mostly applied technical separators, because it has applicationwise some fundamental advantages. One of them is certainly the fact that its construction does not show any movable components. For the large variety of different kinds of dispersed (particulate) phases (for example dust particles, metal chips, wooden waste, liquid droplets) and different gas conditions (pressure, temperature) the lay out and computation of a cyclone is still a complex task. Suvis has specialised in the development and lay out of cyclone separators and can offer professional solutions and consulting in the area of gas cyclones. Many years of experience gained through numerous cyclone development projects results in optimal solutions for our customers. A cyclone separator applies centrifugal forces and represents an effective apparatus for separating gas, liquid or solid particles from a continuous phase in chemical, process or environmental engineering.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

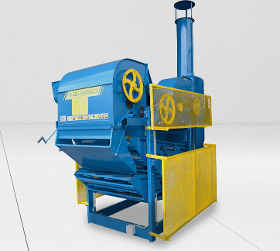

The universal seed separator with cyclone OBC-355C is the most multifunctional drum separator for cleaning any grain and seeds. The number of applications for this separator exceeds 50. This is achieved through an innovative block design with a large number of reversible valves and an additional auger at the bottom of the cleaning unit. The main parts of the OBC-355C are the OBC-355 seed separator and the aspiration system, to the outlet of which a cyclone with 3 supports is connected through an air duct. Grain separators OBC-355C have the following main advantages: Maximum versatility in application. Greater cleaning efficiency. High accuracy of grain calibration by aerodynamic properties, width and thickness. Minimal vibration during operation. Fast replacement of sieves. Gentle handling of seeds and grain. Adjustable performance. The presence of a cyclone that traps dust and light impurities. For more information about the advantages of OBC-355C, see the plant’s website.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The OBC-25SC grain cleaner cleans any grain using 8 sieves and an aspiration system with a built-in cyclone. The installation of a cyclone at OBC-25SC made it possible to solve the problem of cleaning the air emitted by the OBC-25SC fan from dust and light impurities (small parts of leaves, grains, insects, sand, etc.). Previously, this was solved by installing a separate cyclone near the OBC-25S, conducting an air duct from the OBC-25S fan to it, and installing a clean air exhaust system from the cyclone. This led to significant additional costs and required a large free space. Now OBC-25SC with an integrated cyclone that successfully copes with cleaning a heap of grain, saves space and money. Additional advantages of the grain cleaning machine OBC-25SC: - high productivity with small sizes; - simple, durable design; - quick sieve change; - automatic cleaning of sieves with built-in brushes; - can be equipped with lifts, cyclone pipe and wheels.

Request for a quote

OMEGA AIR

Slovenia

CS condensate separators are designed for high efficient removal of bulk liquids and large impurities from compressed air systems. The insert inside the housing creates controlled rotation of the air flow. Centrifugal flow of liquids (water, oil) and large particles is forced to the housing wall, slowed down and accumulated at the bottom of separator housing as condensate. The turbulent free zone in the lower part of the cyclone housing prevents condensate from being picked up and “carried over” into the airstream. To discharge condensate from the CS cyclone separator it is essential to install automatic or electronic condensate drain. CS cyclone separators are also available in stainless steel version CS-SS.

Request for a quote

OMEGA AIR

Slovenia

SFH condensate separators are designed for high efficient removal of bulk liquids and large impurities from compressed air systems. The insert inside the housing creates controlled rotation of the air flow. Centrifugal flow of liquids (water, oil) and large particles is forced to the housing wall, slowed down and accumulated at the bottom of separator housing as condensate. The turbulent free zone in the lower part of the cyclone housing prevents condensate from being picked up and “carried over” into the airstream. To discharge condensate from the SFH cyclone separator it is essential to install automatic or electronic condensate drain. SFH cyclone separators are also available in stainless steel version SFH-SS.

Request for a quote

SAMES KREMLIN

France

Automatic Cleaning System for the applicator spray head Description Automatic cleaning of the contamination on the atomizer. It is specially designed for atomizers like ACCUBELL® and PPH models (equipped with all the existing types of bells : ø35 mm, ø50 mm, ø65 mm or ø80mm). Performance Air shroud cleaning device for a steady application Air/material cyclonic separator Productivity Increase your working time by reducing production stops Automatic process managed by paint automation Sustainability Reclaiming all cleaning material Operators spend less time cleaning with solvent

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Force-of-gravity separators, which are used as pre-filters or for the separation of large quantities of dust and swarf. Cyclone separator Cyclones are force-of-gravity separators. The separation principle is based on centrifugal force, which is produced by the tangential injection of the raw air. Cyclones are used as pre-filters or for the separation of large quantities of dust and swarf. The degree of separation of a cyclone is not normally sufficient to meet the usual environmental protection requirements. The cyclone exhaust air must be post-filtered in most cases. Product description A cyclone essentially consists of three parts: the intake cylinder, the cone and the immersion tube. In the intake cylinder, the raw air is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air stream and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube. Cyclones are usually welded sheet steel structures. Cellular wheel sluices or, in individual cases, double-gate sluices are used for the pressureless discharge of the material. In order to increase the cyclone effect, or the degree of separation, counter-spirals with a pipe connection can be placed on top of the immersion tube. Further options are, for example, wearing devices, explosion pressure relief devices, control flaps, level monitoring devices and manufacturing in stainless steel or galvanised sheet steel.

Request for a quote

OMEGA AIR

Slovenia

WOSm water oil separators have been developed to separate lubricant oil from condensate generated in compressed air systems. Due to patented technology regular service can be done in 30 seconds without any cleaning. Separation begins in “cyclonic depressurization chamber” and continues in “filter cartridge”. When the “filter cartridge” is fully saturated you just simply unscrew complete cartridge and replace it with new one. All the condensate stays in old cartridge which can also be sealed with plastic cover and disposed according to local directives and laws.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Separation of paint powder from powder coating booths. Options: Rippert powder filter This type of filter is particularly suitable for the separation of paint powder from powder coating booths and is also often used together with an upstream Rippert cyclone for powder recovery. Separation chamber with dust collecting container, filter cartridges, compressed air cleaning and sound-insulated fan are housed in a compact design. The filter cartridges are arranged vertically in order to ensure optimum cleaning behaviour and energy-efficient operation. The fan, which also comes from our own production, is characterised by smooth running and high efficiency. Standard advantages:

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The Grain Impurity Screen is used for cleaning different size of the impurities in the materials, such as seeds, wheat, nuts, corn, etc. Raw materials after fed into machine by elevator, light impurities and dust were sucked out through double direction of gravity catcher; The left materials enter into vibratory sieving trunk, there are two layers of sieves and the first layer can separate coarse impurities (large pieces of wood, strings and straw) bigger than the grain, while the second layer can separate fine impurities (sand and broken grain) smaller than the grain. The sieves has vibration mechanism to ensure better cleaning process by adjustable angle of engine, and rubber balls inside for the self-cleaning. This product is widely used in agricultural product processing industry of various materials, and it has become the preferred choice for a grain cleaning machine. It can be applied to the assembly line to achieve the automatic work with cyclone dust separator or pulse

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Various heater types available, eciency and robustness characterise directly heated drum dryers by Büttner. They are used for drying wood particles, strands, sugar beet pulp and all free-owing types of wood, biomasses and bulk solids Features Water evaporation capacity of up to 80 t/h depending on the product Direct heating system with multi-fuel burners in combustion chambers Direct heating system using ue gases from energy plants Direct heating system using waste gases from turbines or engines All combinations of these types of heaters are possible. A ash tube may be used for pre-drying and oversize separation of material that is quite moist. Material separation via cyclones or drop boxes Function The material to be dried is admitted through an air-tight rotary air lock into a rotating single-pass drum dryer. The dryer drum can be tted with specic internal ights to suit the material to be dried. This results in an increase in surface area and thus an increase in eciency

Request for a quote

SUVIS GMBH

Germany

Hydro cyclone units are applied in order to separate coarse and fine solid particles from liquids . These type of separators are particularly capable of separating sand, starch, and other finely distributed materials. With hydro cyclones it is possible to separate fine particles online during the process. Hydro cyclone units are used to separate, classify, and to thicken suspensions. Also, these units are used to purify ores and minerals. Also, in fibre technique and paper industry they are applied in purification processes to separate dirt. Hydro cyclones are frequently run in parallel mode. The lay out and design of hydro cyclones are performed empirically similar to the duct cyclones. In the lower flow region of a hydro cyclone an air swirl forms during the separation process, which is not substantially influencing the cyclone flow. Because of the large dimension of the cyclone, wall friction has much more influence on the flow.

Request for a quote

SUVIS GMBH

Germany

The Suvis GmbH also deals with the application of modern numerical methods for the lay out and optimisation of various separator types like cyclones. A typical application of these computation methods is the computer aided investigation of particle separation from gases in cyclones. The prediction of the separation efficiency allows the reliable optimisation of conventional cyclones and the development of completely novel high efficiency cyclones. With that, very often expensive filter units, wet cleaner, or costly electro filters can be replaced or completed. When applying numerical methods (CFD simulations) to cyclones one encounters the problem of strong curvature of the stream lines because of the resulting strong swirl flow and the abrupt change of flow direction towards the outlet tube. This means that the assumption of isotropic turbulence is not useful anymore.

Request for a quote

SUVIS GMBH

Germany

A further area of activity of Suvis is the development and application of modern numerical methods for the calculation (prediction) of flows using CFD in industry, science etc. Our employees are especially trained in view of technical applications of numerical flow simulations. Within the recent years we conducted several projects in the area of multiphase flows. We dealt with applications in the optimisation of processes in chemical engineering, the transport of particles, gas cleaning and particle separation from gases and liquids, and the calculation and optimisation of cyclone separators. We apply powerful commercial software tools like grid generators in order to generate numerical grids using CADdata in a short time for even complex applications. Also, for flow calculations and the evaluation of 3D flow fields we apply powerful software solutions. Furthermore, for certain individual problems we apply codes we have developed our selves.

Request for a quote

CASTSERVICE GMBH

Germany

Special heat resisting and wear resisting materials are needed in the limestone and cement production. Already since many years we develop and supply high quality casting parts that fulfill these requirements and extend the service time of your production facilities. In order to achieve this, we produce tailored products in close collaboration with our customers that are designed to meet the special demands. We also consult you in questions regarding the choice of the materials and the design. In addition to that, CS-specific-materials and CS-design-developments show our capability.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OFFICINE CONTERNO SRL

Italy

Officine Conterno supplies various machines for sand washing and recovery, including cyclonic separation units. Sand Classification Units with hydrocyclones are systems composed of a sand + water receiving tank (turbid), a suction head or immersion launch pump, a hydrocyclone for concentration of the sands and a vibro-dryer for drainage and drying. The sizes of the various components will vary depending on the quantity and concentration of the turbid matter.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Officine Conterno designs and manufactures crushing, screening and aggregate washing plants for the production of concrete, bituminous conglomerates, road foundations or railway ballast. Jaw crushers, primary, secondary and tertiary mills, feeders, rotating screens, vibrating screens, vane or barrel scrubbers, and cyclonic separation groups ... These are just some of the machines in our product range.

Request for a quoteResults for

Cyclone separators - Import exportNumber of results

20 Products