- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- crushing and screening

Results for

Crushing and screening - Import export

ECSMT MACHINERY EQUIPMENTS

Turkey

ECMT RUROMIX EMI130 Crawler Mobile Counterattack Crusher Station Strong and stable, Best quality, Long service life and low operating cost, Effectiveness and efficiency.

Request for a quote

ILK IHRACAT AS.

Turkey

At steeling.net, we manufacture high-performance screens for stone crushing and recycling machines, designed to meet the rigorous demands of these applications. Utilizing advanced laser cutting, CNC bending, and precise welding techniques, our screens ensure superior durability and efficiency. Perfect for various crushing and recycling operations, these screens are engineered to provide optimal material separation and sizing. Each screen is custom-made to fit specific machine types and requirements, ensuring seamless integration and maximum productivity. Constructed from robust materials, our screens are built to withstand the harshest conditions, offering long-lasting performance and reliability. Trust steeling.net for durable and efficient screens that enhance the effectiveness of your stone crushing and recycling processes.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

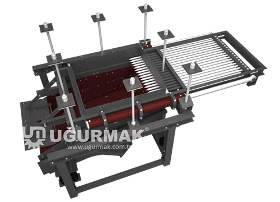

UMHS series Horizontal Screens show the innovative aspect of UĞURMAK. It provides high performance, even in the most demanding applications, and demonstrates its quality and reliability. It shows high efficiency compared to traditional horizontal screens making linear motion. With this design, the timing system eliminates the need for difficult maintenance equipment such as the gear system.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK UMB Series sand bunkers are used in the crushing and screening processes to make intermediate stocks in the stages after the primary crushing stage and to ensure the continuous feeding of the machines in the subsequent stages.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK CDK Series Primary Impact Crushers have a design that allows the rotor, two pendulum systems and wear plates to work in harmony. Thanks to this compatibility, it offers high performance and low operating costs. It can provide very high size reduction ratios in breaking not very hard and non-abrasive materials. Thanks to these advantages, they are preferred in primary crushing stage in crushing and screening plants. According to the design of the facility, they can be manufactured as mobile, with fixed steel legs, with fixed concrete legs, with fixed skid chassis.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK brand SMK Series Secondary Impact Crushers can crush medium and high hardness materials such as limestone, dolomite, granite and basalt to the size of asphalt and concrete aggregate. Large size material from the primary crusher can be fed directly. High reduction rate is provided. It is the most preferred secondary crusher type in crushing and screening plants since the initial investment and operating costs are lower than other crusher types. According to the design of the facility, they can be manufactured as mobile, with fixed steel feet, with fixed concrete feet, with fixed skid chassis, pre-screened or pre-fed.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK UDK Series Vertical Shaft Impact Crushers are preferred at the last stage of the crushing and screening process. They have a high production capacity. It successfully performs to break wet, moisty and sticky materials. Moreover, such fed materials get rid of some of the water in the body with the kinetic energy that emerges when it collides with the rotor rotating at high speed. Therefore, the end material is relatively drier. Thanks to these advantages, it is highly demanded for use in the production of sand and gravel necessary for concrete and asphalt production. Depending on the design of the facility, it can be manufactured as mobile, with fixed steel legs, with fixed skid chassis or with front feed.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

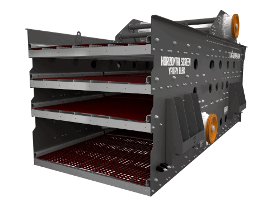

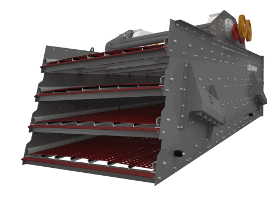

UĞURMAK UME series Inclined Screens provide separation of crushed material. It can be used in all the stages of a crushing and screening process, where it is necessary to classify the products by size. The main task is to receive the end product. Therefore, the screen determines the actual capacity of the process. UME series inclined screens have a more reliable body structure against the negative effects of vibration movement with its unique body design.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UGURMAK UMG Series Vibratory Grizzly Feeders are the main feeder type used in crushing and screening plants. They take place for feeding jaw or impact crushers used in primary stage. Offering high performance even in the harshest conditions, UMG Series feeders can be used for any size of material, from oversized material to small size stream materials. Thanks to the adjustable grill distance, the product size that cannot be included in the primary stage can be changed. It has a very solid chassis. Feeder body is seated on it with helical springs in sufficient number and strength. On this feeder body, there is a large volume bunker in the structure offering high strength. It can be used in all mobile and stationary primary units.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

In some crushing and screening processes, there may be a need to divide the process in half. In such cases, tunnel type intermediate stock center is frequently preferred. It is positioned in the middle of the stock center. Their main field of use is to ensure that the stocked material is fed to the second stage of the process. This vibrating feeder type UTF series Tunnel Feeder provides high performance in heavy conditions

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK UMBB Series Vibrating Feeders are positioned in the intermediate stock points, at the exit of the silo or bunker where the material is stocked, in order to ensure continuous feeding of the machines at all stages after the primary crushing stage in crushing and screening processes.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK USB Series stock bunkers are used for the stockpiling of materials that turn into the final product in the crushing and screening process. The materials classified according to their size in the product screens used in the final stage of the process are collected either in the stock bunkers or directly through the screen via a belt conveyor.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

As a crushing and screening company, we should consider our crawler crusher as both a crushing plant and the wonderful collaboration of all it’s components. Its easy movement and breaking of all natural rocks, Concrete and asphalt wastes are the determining roles in its selection.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

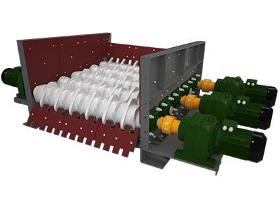

UĞURMAK UWB Series Wobbler Feeder is a necessary equipment of the crushing and screening process in case the blasted material has high moisture and sticky. The monolithic rollers, which are produced as steel cast, with discs arranged in a triangular form and offset from each other, are the main elements of the wobbler feeder. Shaft is in square form and is connected to the gearmotor by coupling. It transfers this motion to the roller thanks to its square form that receives the movement from the engine. The consecutive rollers move synchronously with one another. Thanks to this movement the compression and friction force formed between the advancing material and the disk parts of the rollers, the mud and sticky particles, thin and / or waste particles, are separated from the material and transmitted to the lower groove of the wobbler. Unwanted material is removed from the process before it reaches the main crusher.

Request for a quote

DUTCH SCRAP RECYCLING B.V.

Netherlands

Carbon Anode Butt Carbon Anode Scrap/ graphite scrap 1.for copper smelting 2 replace foundry coke as fuel 3 well cleaned Features: 1.Anode scrap is high in calorific value and low in moisture; 2.Anode scrap can be divided into different sizes by crushing and screening, including 10cm, 20cm above and powder. 3. It can also be used as the smelting fuel.

Request for a quote

TURKISH MANUFACTURERS UNION

Turkey

Our company started to operate in machinery manufacturing sector in 2007 in addition to consultancy, project and feasibility studies made to companies in mining sector. Thus, it is aimed to improve the efficiency of the machines manufactured as well as the projects. The selection of Crushing-Screening-Enrichment technologies and processes applied in the recovery of various mines and minerals is very important. The effect of enrichment machines selected for this purpose on production is just as important. Lack of the number of R & D companies in the workshop and production area on the efficiency of ore enrichment machines has been one of the most important factors in our activity in this sector.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KMC GLOBAL EUROPE SP. Z O. O.

Poland

VPH type Vibrating Hybrid Screeners in their unique design combine the features of the VPI type screener with the classic screener. The VPH Hybrid Vibrating Screener is a device designed to use a high-performance screening process for materials with properties that make it difficult to screen, such as: High humidity Caking The tendency for the sieves to grow together with the material Low installation height Thanks to the unique design of the device, in which two types of drives operating at different frequencies are used, this screener simultaneously performs the process of crushing and screening of the fed material. This technological solution allows the use of this type of screeners for such works as the process of regeneration of molding sands or screening of fine coal fine fractions.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pattern with uniform distribution throughout pattern area. Even spray impact across the entire spray area. Applications Cleaning: Automotive, containers, films, felts, filters, screens, bottles, crushed stones, earth and sand, metal parts, machines, steel plates and pieces Spraying: Etchants, oils, lubricants, glues, solutions, insecticides, herbicides Cooling: Gas, smokes, heat exchangers, tanks, steels, roofs Water screen: Fire protection, heat protection, dust suppression, deodorization

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pattern with a mountain-shaped spray distribution having gradually tapered edges. Tapered edges overlap to provide uniformity of spray distribution in multiple-nozzle arrangements. Applications Cleaning: Automotive, containers, films, felts, filters, screens, bottles, crushed stones, earth and sand, metal parts, machines, steel plates and pieces Spraying: Etchants, oils, lubricants, glues, solutions, insecticides, herbicides Cooling: Gas, smokes, heat exchangers, tanks, steels, roofs Water screen: Fire protection, heat protection, dust suppression, deodorization

Request for a quote

ECSMT MACHINERY EQUIPMENTS

Turkey

ECMT RUROMIX EM130 CRAWLER MOBILE COUNTERATTACK CRUSHER STATION Strong and stable, Best quality, Long service life and low operating cost, Effectiveness and efficiency.

Request for a quote

PI MAKINA

Turkey

Pi Makina, which has produced the largest Crushing and Screening Facilities in Turkey and the world, produces solutions suitable for every project and need. Pi Makina has installed hundreds of crushing and screening plants around the world and uses its experience in this sector in every new project to offer superior performance facilities tailored to customers' wishes. Pi Makina, which produces any equipment that may be necessary for a crushing and screening plant through its own designs, has a wide range of products such as cone crusher, vertical shaft impact crusher, hammer crusher, jaw crusher, screen sand washer and mobile crushing plant.

Request for a quote

SEDA MAKINA IMALAT TIC LTD STI

Turkey

USED CRUSHING AND SCREENING PLANT FOR SALE PRIMARY IMPACT CRUSHER (160 t/h) SECONDARY IMPACT CRUSHERS (16/18 and 12/12) SCREENS (150/4000, 220/6000 and 120/3000) STOCK PILE (100 t) CONTROL PANEL DUST COLLECTOR

Request for a quote

TEKNO MILLING MACHINES CO. LTD

Turkey

As Tekno Milling Machines Co. Ltd that founded in Mersin Turkey, we offer turnkey completed seed,pulses,cereals,nuts,spices processing screening crushing and cleaning plants also following agricultural machines and spare parts. Seed Cleaning and Processing Machines : Pre-Cleaning Machines,Classical Screening Machines,Excel Cleaners,Destoners,Gravity Separators,Indent Cylinders,Brushing Machine,Liquid Treatment Machines,Color Sorting Machines,Bagging Machines,Dehullers,Millers Packaging machines: Vertical packaging machines,Rotary Type Packaging Machines,Filling Machines,Seed Counting Machines,Bailing Machine Post Packaging Systems: Carton Packing Machines, Streching Machines ,Shrinking Machines,Vacuum Machines,Metal Dedectors,Printers,Carton Coding Machines,Sticking Machines Silo Systems : Elevators,Conveyor Belts,Screw Conveyors,Silo Systems Please visit our website for all.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Officine Conterno designs and constructs machines and mobile plants attached to wheels, tracks, roll-offs or sleds. These plants do not come in a standard model but are studied and designed to suit individual customer requirements. Precisely for this reason we are able to provide the most diverse range of mobile machines, from single conveyor belts on tracks to roll-off crushers up to complete crushing and screening plants.

Request for a quote

OFFICINE CONTERNO SRL

Italy

Officine Conterno designs and manufactures crushing, screening and aggregate washing plants for the production of concrete, bituminous conglomerates, road foundations or railway ballast. Jaw crushers, primary, secondary and tertiary mills, feeders, rotating screens, vibrating screens, vane or barrel scrubbers, and cyclonic separation groups ... These are just some of the machines in our product range.

Request for a quote

OFFICINE CONTERNO SRL

Italy

The major and growing concern for the environment and the reduction of raw material consumption has led to the design of waste recycling plants with a high technological value and low environmental impact. Officine Conterno is able to manufacture complete plants for the recycling and exploitation of aggregates of various kinds such as: BUILDING DEMOLITION RUBBLE BRICK PROCESSING SCRAPS STEEL AND FOUNDRY SLAG UNBURNED ASHES FROM MSW INCINERATORS FLAT AND HOLLOW GLASS SCRAP After undergoing a crushing process, iron removal, screening and separation of non-ferrous metals, all these materials are placed back on the market and are used in building and industry.

Request for a quote

OPT MAKINE

Turkey

Jaw crushers are the type of crushers used to reduce big-size rocks by compression, i.e. by mechanical pressure applied by two jaws of the crusher. These crushers are used as primary and secondary crushers in crushing plants. Jaw crushers are mostly preferred crushers because of their ability to crush all kinds of materials of any hardness. Our jaw crushers assures low and easy operation & maintenance cost. Our range of jaw crushers includes 6 different types of Primary and Secondary jaw crushers from 610 x 380 mm type to 1300 x 1100 mm mouth opening. The high performance, reliability, durability and user-friendly adjustment mechanisms of our jaw crushers due to their high flywheel speeds, jaw grabbing angles, special geometries of their pits with safety plates and rear blocks provide unique operating advantages to its users.

Request for a quote

OPT MAKINE

Turkey

Mobile Solutions PORTABLE CRUSHING AND SCREENING UNITS Mobile units are right solutions when temporary aggregate production is required for short-term projects, like road and dam construction. As most of the time the equipment is moved out of the temporary quarry, disassembly, transportation and installation expenses add extra costs that can be just as significant as the start-up investment itself. In such cases, despite higher initial investment costs, mobile crushing and screening solutions are better options than stationary ones because of the time-saving disassembly, transportation and installation advantages they provide. Advantages: -Compact, -Easy to setup, -Less space required, than stationary units. Mobile jaw crusher Mobile vibrating grizzly feeder Mobile impact crusher

Request for a quoteResults for

Crushing and screening - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Crushing and grinding machinery (20)

- Mining and quarrying - machinery and equipment (3)

- Building materials, manufacture - machinery and equipment (2)

- Nozzles - ferrous metal (2)

- Agriculture - Machines & Equipment (1)

- Carbon and graphite - electrical components (1)

- Concrete constructions (1)

- Excavation - works (1)

- Goods handling systems, continuous (1)

- Metal packaging machine (1)

- Metal screens for reinforced concrete (1)

- Minerals (1)

- Turning - steels and metals (1)