- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- covers for conveyors

Results for

Covers for conveyors - Import export

POR METAL URUNLERI INSAAT TURIZM VE SANAYI TICARET LIMITED SIRKETI

Turkey

These are special solutions applied for secondary areas. Conveyor bottom covers are a good example of such applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Skipper Conveyor is probably the most novel and technological advancement attributed to conveyor systems meant to streamline handling and distribution exhaustively used across a wide array of industries. Unlike the traditional style of conveyor systems, Skipper Conveyors are designed with diverter chutes or gates along the conveyor line. These chutes can be actuated to selectively direct materials to diverse discharge points or processing areas based on stipulated criteria such as size, weight, or destination. The capability of selectively distributing therefore makes Skipper Conveyors very useful; for instance, the separation and the direction of materials to many various stages of the production process are needed. An automated control system can also be integrated into the design of a Skipper Conveyor, which can control a diverter chute based on real-time data or according to an instruction that has already been programmed.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A track stacker is versatile, mobile equipment mainly utilized in the bulk material handling industry. With their tracked ability to move, these stackers are designed to move and stack materials such as soil, sand, aggregates, and other bulk goods. They find their most important applications in operations that call for efficient stockpiling and accurate placement in large quantities. Their tracked mobility enables them to operate in areas that might not be accessible for conventional wheeled stackers; hence, they become ideal for mining, construction, and recycling sites. These machines can deal not only with huge volumes of materials at higher speeds but the precision with which they work makes them very critical in the workflow in order to optimize storage and processing space.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Apron conveyor is widely used in industry because it works steadily and it is easily cleanable and portable. Covers on both sides of the conveyor ensure there is no material exposure. The overall sizes and angles of the machine are adjustable to suit the designs desired by the customers. Materials in flake or powder form, such as food or chemicals, are best suited for this type of conveyor. Wheels attached to the bottom of the frame provide convenient mobility.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

The screw conveyor conveys the material using the rotation of the screw blade and controls the discharge volume through the size and speed of the screw blade. There are two types of screw conveyor: U-shaped screw conveyor with top cover and tube screw conveyor. The advantage of the screw is that it avoids the dust problems specific to the outlet connected by a closed circuit. It is suitable for conveying various powders. The power end comes with different storage drum options.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Original Wire Belt dragmats offer you the highest quality with a long service life. Our weatherproof design is ideal for the uncomplicated introduction of fertilizers, granulates, seeds and sand as well as for removing and roughening plazas. The movable links adapt perfectly to unevenness and the ground. A double-sided use is possible without any problems, as is pulling by hand or by machine. They are used in the maintenance of golf, football and rugby fields, in horse stables and riding facilities and are indispensable on tennis, beach volleyball and grand courts. Optimal, particularly thorough and uncomplicated processing of your floor covering with Wire Belt dragmats.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Original Wire Belt dragmats offer you the highest quality with a long service life. Our weatherproof design is ideal for the uncomplicated introduction of fertilizers, granulates, seeds and sand as well as for removing and roughening plazas. The movable links adapt perfectly to unevenness and the ground. A double-sided use is possible without any problems, as is pulling by hand or by machine. They are used in the maintenance of golf, football and rugby fields, in horse stables and riding facilities and are indispensable on tennis, beach volleyball and grand courts. Optimal, particularly thorough and uncomplicated processing of your floor covering with Wire Belt dragmats.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

BEHRINGER vertical bandsaws are the perfect answer when it comes producing cuts in all plate dimensions and thicknesses with optimized contours and machining allowances. LPS bandsaws can be ideally tailored to meet your specific needs. The material table is structured using platform technology and can be variably equipped in 250 mm graduations with cover plates, liftable roller conveyor segments, recesses for crane loading on chains or measurement and clamping devices. Every machine is unique to its owner. The LPS vertical bandsaws are able to cut even materials with different machining properties with the utmost precision without compromising on speed. This is made possible by a durable design in combination with vibration-damping grey cast iron components. Saw feed is performed here by a ball screw with servo drive and the sensitive BEHRINGER cutting pressure control system.

Request for a quote

CL MACHINERY GMBH

Germany

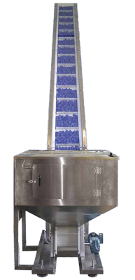

Closure Systems International's closure elevator pre-feeders are designed to feed closures to sorters from the ground level. Via a cleated belt, closures are fed from a bulk storage bin at ground level to a sorter mounted on a capping machine. CSI Closure Pre-Feeder Features & Benefits Stainless steel construction Bin sizes available: ✓ 10 cubic feet ✓ 25 cubic feet ✓ 50 cubic feet ✓ 100 cubic feet Can be custom designed to meet any delivery rate Can be custom designed for any closure size and type Clean-out door for quick changeover Lexan bin cover for clear visibility Lexan conveyor cover to keep dust out High and low level photo sensors Self-contained stainless steel control panel Controls can be integrated with capper controls Best to be combined with a rotary sorter and placed next to the capper Markets Served: Beverages, Food, Pharmaceutical, Automotive Fluids, Personal Care, Home Care, and Custom Applications Unmatched Technical Support / Application Expertise!

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK Förderband Technik Kilian GmbH has enjoyed renown for belt conveyor hooded covers made of metal for many years. We have decisively extended our product range with the sale and distribution of plastic cover hoods. Due to statutory requirements, different sectors of industry require alternatives to the metal systems. In particular, the industries of food, sugar, chemicals, potash and salt are reliant on hooded covers made of Organit plastic. The corrosion resistant hoods reliably protect conveyor belt, roller bearings and the material conveyed against the weather. They can be easily removed at any location so that the conveyor belt can be inspected and then replaced. Organit conveyor belt hooded covers made of rigid PVC, transparent and natural, in sheeting pile 70/18 have the following features hardly inflammable DIN standard 4102 impact resistant DIN standard 7748 chemically stable DIN standard 16929 maintenance free low weight easy handling

Request for a quote

PACTUR

Italy

Products from Pactur are available in different sizes (TL/30, TL/70 and TL/80) obviously depending on the size of the products, around which the bag must be heat-shrinked, which is wrapped by the various packaging machines. Within the range of heat-shrinking tunnels, there are three types, available for each model: Teflon mesh conveyor tunnel; tunnel with metal rod conveyor belt, covered with silicone rubber; wire mesh conveyor belt. These variants allow the shrink oven to be adapted to the shape of the product, the type of film used to bag it and the desired shrink result. For example, for light and irregularly shaped products, Teflon mesh carpet is suitable. On the other hand, if the products must present a remarkable aesthetic result, with an excellent retraction effect also on the underside, the optimal solution is the tunnel with silicone bar belt. On the other hand, when the film used is polyethylene, when the products are heavy and the

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanBelt® chevron conveyor belts are used to transport material at steep angles of more than 20o. In contrast to smooth fabric belts, chevron conveyor belts are equipped with cleat profiles with heights of 17 mm and 35 mm that enable the belts to meet the specific requirements of steep angle transport. Divers cover qualities and a variety of profile heights provide a wide range of application. Transport of sand, gravel or stones/rocks; Transport of oil-containing or hot material as, for instance, in the recycling industry. germanBelt® chevron conveyor belts offer significant cost benefits and ensure highly reliable transport. In the following, you are provided with an overview of the most frequently requested germanBelt® chevron conveyor belt configurations. If you have special requirements as to profile height or cover quality of chevron conveyor belts we also offer tailor made individual solutions and give you advice on how to deal with your specific transport problem.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

Structure of germanBelt® steel cord conveyor belts Steel cord reinforcement: The standard steel cords have been hot-dip galvanised and have diameters from 2.6 to 12.8 mm. They are manufactured in 7x7 or 7x19 designs (other designs are possible). Their design allows good rubber saturation and distribution. Skim layers: A special chemical process provides excellent rubber/metal adhesion in the steel cord conveyor belt. The design of the steel cords leads to outstanding adhesion that surpasses any standards. Good rubber saturation and high adhesion on each cord provide germanBelt® steel cord conveyor belts with extraordinarily high longevity. Covers: The covers’ abrasion resistance, tensile strength and elongation value depend on the quality of the chosen combination of covers of the steel cord conveyor belt. Lateral reinforcements: The steel cord conveyor belts’ reinforcements consist of lateral steel cords with very high elasticity, or of textile fabric. The lateral reinforcements are worked into the carcass or the cover.

Request for a quoteResults for

Covers for conveyors - Import exportNumber of results

14 ProductsCountries