- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- counter knives

Results for

Counter knives - Import export

MONGIN

France

TYPE OF MACHINES : PERINI, PCMC,FUTURA, ... For your rewinder machine, we produce precutting and counter knives, cutting blades, ..

Request for a quote

MONGIN

France

Pack cutting N°12 - Blade N°13 - Counter blade Toothed knives N°14/15 - Toothed knives

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Only the best for our forests Nowadays, forestry bears responsibility for numerous important tasks and is increasing not only in its commercial, but also in its environmental and social significance. In addition to continuous production of renewable raw materials (mainly wood) it is assuming the task of forest conservation, not least as a protected and recreational space for mankind and the animal kingdom. The predominantly municipal forestry operations are directed for the performance of these tasks at mobile woodcutters and robust wood chipping machines. We have supported the forestry industry for many years with our longlasting choppers and counterknives, as well as with shredder knives.

Request for a quote

COMERC SP. Z O.O.

Poland

Skorpion 650 EB is a stationary drum chipper designed for chipping flat edgings, round timber, various types of furniture and sawmill waste of a width to 650 mm. The drive section of Skorpion 500 EB chipper is a 90 or 110 kW slow-running electric motor. In contrast to high-speed motors, this motor is features more stable operation and higher torque. A slow-speed motor with the same power achieves greater energy transmission, and by increasing the diameter of the pulley on this motor, the service life of the V-belts is extended. The cutting system of the chipper includes a drum with 2, 3 or optionally 4 cutting knives and 1 counter-knife. Screen used in the construction of this chipper ensures high regularity in size of the product. The required size of chips can be obtained by adequate configuration of suitable number of knives on the drum and the diameter of holes in the screen.

Request for a quote

COMERC SP. Z O.O.

Poland

Skorpion 500 EBis a stationary drum chipper designed for chipping flat edgings, round timber, various types of furniture and sawmill waste of a width to 500 mm. The drive section of Skorpion 500 EB chipper is a45 or 55 kW slow-running electric motor. In contrast to high-speed motors, this motor is features more stable operation and higher torque. A slow-speed motor with the same power achieves greater energy transmission, and by increasing the diameter of the pulley on this motor, the service life of the V-belts is extended. The cutting system of the chipperincludes a drum with 2, 3 or optionally 4 cutting knives and 1 counter-knife. Screen used in the construction of this chipper ensures high regularity in size of the product. The required size of chips can be obtained by adequate configuration of suitable number of knives on the drum and the diameter of holes in the screen. The control system of the chipper consists of a control cabinet with functions of switching on, work control

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

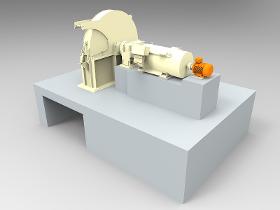

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Disc chippers are especially suitable for processing straightly grown round wood into high quality wood chips. The raw material is fed into the chipper via a slanted horizontal feeding conveyor. The disc inside the housing is equipped with knives. The logs are processed to chips between the vertical rotor knives and the counter knives. The chips are discharged below via a discharge chute, with lling level control, to a subsequent conveyor. Advantages High, consistent chip quality Quick, ergonomic knife changes Cutting force supports material infeed Features, Function Chip length 20-25 mm Chip width 4-10 mm Options Adjusting devices for rotor and stator Knives

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Disc chippers are especially suitable for processing straightly grown round wood into high quality wood chips. The raw material is fed into the chipper via a slanted horizontal feeding conveyor. The disc inside the housing is equipped with knives. The logs are processed to chips between the vertical rotor knives and the counter knives. The chips are discharged below via a discharge chute, with filling level control, to a subsequent conveyor. Features, Function Chip length 20-25 mm Chip width 4-10 mm Chipping disc with large flywheel effect Robust, double-sided disc bearing Electro-mechanical locking during knife change Quick knife changes Re-grindable knives Advantages High, consistent chip quality Quick, ergonomic knife changes Cutting force supports material infeed Options Adjusting devices for rotor and stator knives

Request for a quoteResults for

Counter knives - Import exportNumber of results

8 ProductsCountries

Company type