- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- corrosion-resistant metals

Results for

Corrosion-resistant metals - Import export

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

We offer a comprehensive range of super mirror marine polished stainless steel tube in grade 316 (1.4401). The size range covers tubes from ½” (12.70mm) – 2.1/2” (63.50mm) with a 16 gauge (1.6mm) wall thickness. Suitable for marine environments and high-chloride exposure.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

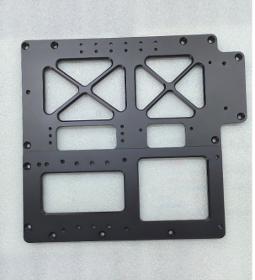

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

[Easy to use] The lergth of hose is 19", come with clear gauge for viewing. R-134a quick coupler can oe easily connected to the R-12 / R-22 1/4" SAE port side. Perfectly fit for R-134a, R-12, and R-22 refrigerant. [Applicaoility] BPV-31 Pullet piercing valve compatiPle with 3 different sizes of tuDing: 1/4", 5/16', 3/8* (outside diameter pipes). The gauge with 3 type scale readings for R134, R12 and R22. [High Quality] Made of corrosion-resistant metal and the hose adopted quality ruooer material, high pressure resistance and sturdy [Repalcement Part] AP4502525, BPV31D, MPV31, GPV14, GPV31, GPV38. GPV56 [Package including] 1 x charging hose with gauge. 1 x r134a low skje quick coupler, and 3PV-31 piercinq tap valve kits (1 x piercinq valve, 1 x hex key and 2

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

BN is a material with non-wet feature. So molten metal won’t be sticked onto the nozzle. Additionally, Boron Nitride ceramic is a kind of refractory ceramic with low expansion and high thermal conductivity. These features make it to be an ideal choice as atomizing nozzles. It's very easy to be machined to custom design with precision and tight tolerance because of its machinability. Boron Nitride Ceramic BN Nozzles Performance: 1.The optimized formula and unigque process make it highly resistant to thermal shock and high-temperature creep.Maximum using temperature 1700°C. 2.Low thermal expansion coefficient,no cracking or deformation during use. 3.Strong erosion resistance,wear resistance and metal corrosion resitance.Long service life. 4.Good raw materials,process control,product stability. 5. It is used in Amorphous Ribbon Making and amorphous nozzles.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The protective tube of silicon nitride material has high thermal conductivity, high temperature resistance, corrosion resistance,non-wetting with molten metal, and electrical insulation, making it the best choice for heating body protection tubes. The advantage of the immersion holding furnace is very obvious, and in order to achieve the immersion of the heating element into the molten metal, it is necessary to have a protective tube which can protect the heating element well. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Cu-Ni 715 is a copper-nickel alloy that is resistant to corrosion in sea water. The alloy has good fatigue strength and relatively high thermal conductivity. This alloy is used mainly for flexible metal foil heaters. The alloy is readily formed in the annealed temper, and can be joined by the standard welding, brazing and soldering processes. Available Sizes: Cu-Ni 715 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.010” (0.0127 mm to 0.254 mm) in widths up to 12” (304.8 mm). The material conforms to ASTM B122 and UNS C71500.

Request for a quote

A & C DUSTBINS & WASTE BINS WEBER GMBH & CO.KG

Germany

Nominal volume: 660 L Nominal loading capacity: 270 Kg + manufactured by compact injection moulding process from high molecular weight, high-density polyethylene (HDPE) in accordance with the test + regulations of DIN EN 840 and RAL GZ 951/1 + resistant to frost, heat and chemicals; stabilised against UV radiation + standard emptying options of either DIN or comb-lifting device; optionally with Ochsner handles of zinc-plated steel + quiet-running, full rubber heavy-duty castors of 200 mm diameter, 360° swivel range + wheel stop brake system (dual stop) as standard feature; alternatively available with central braking system + zinc-plated, corrosion-resistant metal parts + frontal comb is equipped with a chipnest to accommodate data carriers in accordance with DIN 30745 and RAL GZ 951/1 + optimised for high stacking with strong stacking ribs + drain plug in the bottom facilitates cleaning + available colours: grey, blue, brown and green

Request for a quote

A & C DUSTBINS & WASTE BINS WEBER GMBH & CO.KG

Germany

Nominal volume 1100 L Nominal loading capacity 144 Kg + manufactured in accordance with the regulations of DIN EN 840 (Parts 3, 5 and 6) and RAL GZ 951/1 + are suitable for both DIN and comb-lifting devices (form A in accordance with EN 840-3) + easy-to-move, spring-supported sliding lid, lockable in three positions + high-quality high-density polyethylene (HDPE) + UV stabilised, resistant to frost, heat and chemicals + 200 mm diameter quiet-running, solid rubber heavy-duty castors, 360° swivel range + available with wheel stop/double stop or central braking system + corrosion-resistant metal parts + the lid is attached to the body with high-strength polyamide hinges. Corrosion-protected metal springs keep the lid closed + can be easily moved from all sides by using the four lateral handles on the body + the waste bin features a standard water drain (2 inch water drainage hole) + available in all usual colours and combinations (e.g. grey, blue, brown or green)

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Nickel alloys display high strength and excellent corrosion resistance, making it a great metal for use in highly corrosive environments and high temperature environments. Hamilton Precision Metals offers an array of high-performance nickel alloys that are engineered to withstand a variety of severe operating conditions.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Material and design in compliance with section 7.3 (Tubing Installation) of the Norwegian offshore standard Norsok Z-010 (Revision 3, published in October 2000 ), API RP 552 and NACE SP 0108-2008 (section 13) Clamp body made of flame-retardant PP-V0 plastic material (tested and V0 classified according to UL 94) Integrated anti-corrosion elastomer strips avoid the accumulation of seawater between clamp body and pipe Drainage channels aid the dispersal of seawater (self-draining) ACT Mounting Hardware is made of Stainless Steel V4A (Material Code: W55) with enhanced corrosion resistance by practically excluding metallic and non-metallic impurities during production, processing and handling ▪ Suitable for continuous exposure to temperatures from -25 °C to +80 °C (from -13 °F to +176 °F) ▪ High UV stability of the clamp body material; resistant against seawater, rain and oil ▪ To be used in sub-sea and top-side environments; alleviating the requirement for two different...

Request for a quote

A & C DUSTBINS & WASTE BINS WEBER GMBH & CO.KG

Germany

Nominal volume: 770 L Nominal loading capacity: 310 Kg + from high-quality, high-density polyethylene (HDPE), manufactured by compact injection moulding process + complies with the regulations of DIN EN 840 and RAL GZ 951/1 + tested, monitored and marked with the GS symbol (Tested Safety) in accordance with the German Product Safety Act. + resistant to UV rays, frost, heat and chemicals + fits all standard lifting devices (DIN and comb-lifting); available with Ochsner handles from zinc-plated steel + equipped with quiet-running, solid rubber heavy-duty castors, 200 mm diameter, 360° swivel range, wheel stop as standard feature; also available with central braking system + corrosion-resistant, zinc-plated metal parts + available colours: grey, blue, brown and green, additional colours upon request; all colour pigments used are colour-fast + with chipnest as standard, to accommodate transponders/data carriers in accordance with DIN 30745 and RAL GZ 951/1

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

AMETEK Specialty Metal Products has been a leader in developing roll bonding dissimilar metals for more than fifty years. The advantage of clad materials is the end product combines the superior properties of each metal: Strength, Corrosion Resistance, Lightweight, Cost, Thermal and Electrical Conductivity. As a result, clad products produce a material superior to any of the individual metals taken alone. Clad metals produced by our roll bond technology combine two or more metals into a single sheet or plate that can be cut, welded or formed into a finished part ranging from chemical processing chambers and pressure vessels to small applications and clad pipe. We specialize in cladding stainless steel or nickel alloys to carbon steel as well as triple layer clad plates bonding stainless steel to an aluminum core. Because of the properties offered by clad metals, and the wide variety of cladding and backing materials available today, these metals can be combined to make custom

Request for a quote

BÜCHI AG

Switzerland

Metal-free magnetic coupling bmd 250 i / cyclone 250 i ac Torque: 250 Ncm Temperature range: - 20 °C to +250 °C Pressure range: full vacuum - 60 bar / 1000 psi Stirrer speed: 0 - 2500 rpm Materials: ceramic Metal-free magnetic couplings (bmd 250 i) and stirrer drives (cyclone 250 i ac) feature inert behavior and full corrosion resistance, as no metal can get in contact with the process media. Built in our reactor systems versoclave, polyclave, kiloclave and in combination with pressure vessels in glass or glass-lined steel, we offer complete metal-free solutions.

Request for a quote

VILLINA LLC

Russia

One of the priority areas in the production of Villina pumping equipment was initially the development of a specialized line of pumps designed for pumping harsh chemical fluids. At present, we are ready to offer you Villina high-end lined centrifugal canned pumps having design life of 20 years for pumping mineral and organic acids, alkalis, salts, oxides and anhydrides, including chlorides, as well as alcohols, esters, aromatic hydrocarbons, ketones, aldehydes and other media which contain various concentrations of mordant substances. Modern technology makes rapid progress, and in place of pumps used earlier for transit of corrosive fluids made of chemically resistant yet expensive steels such as KhN65МV, N70MFV, 06KhN28MDT, lined pumps are widely used now. In accordance with para. 51 of the Safety Rules of chemically hazardous production facilities, corrosion-resistant non-metallic coatings (polyethylene, fluoroplastic) can be used to protect equipment and pipelines

Request for a quote

KUPA MOVABLE GLASS SYSTEMS

Turkey

• Patented design that enables long years durability and comfort in use especially suitable for glazing high balconies and threshold applicable spaces • Panel exit guide that closes automatically with panel movement makes easier usage with stores has Utility Model Award • Effective water discharge from bottom rail • Thanks to double latched lock mechanism both on top and bottom rail, enhanced security • Ability to mount on every kind of space with angular panel caps • Easy to mount wheel systems that has Utility Model Award • Profile aesthetic that appeal to modern tastes beside their robust structure • At bottom and on top 4 pieces of wheel systems at total • Totally integrated, elegantly designed wall side aluminium profiles • Enhanced insulation with extra wall side gaskets • Aesthetic, different angular, high quality polyamide panel caps • Corrosion resistant metal accessories

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic

Request for a quote

KELTEKS

Croatia

solidian REMATs are produced of our noncorrosive and extremely strong solidian REBARs. The rebars are attached to each other by durable and solid injection molded crossing points forming the rigid mat. As a result, solidian REMATs are combining the same unbelievable mechanical properties of our solidian REBARs with the efficient handling of a robust mat on site. You do not need to knot together with your rebars in your prefab plant or construction site saving time and money. The solid injection points are enabling that you can walk on solidian REMATs. So what is the argument to still use steel or stainless steel? corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer construction materials are required and the service life is increased

Request for a quote

KELTEKS

Croatia

solidian REMATs are produced of our noncorrosive and extremely strong solidian REBARs. The rebars are attached to each other by durable and solid injection molded crossing points forming the rigid mat. As a result, solidian REMATs are combining the same unbelievable mechanical properties of our solidian REBARs with the efficient handling of a robust mat on site. You do not need to knot together with your rebars in your prefab plant or construction site saving time and money. The solid injection points are enabling that you can walk on solidian REMATs. So what is the argument to still use steel or stainless steel? corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer construction materials are required and the service life is increased

Request for a quote

KELTEKS

Croatia

solidian REMATs are produced of our noncorrosive and extremely strong solidian REBARs. The rebars are attached to each other by durable and solid injection molded crossing points forming the rigid mat. As a result, solidian REMATs are combining the same unbelievable mechanical properties of our solidian REBARs with the efficient handling of a robust mat on site. You do not need to knot together with your rebars in your prefab plant or construction site saving time and money. The solid injection points are enabling that you can walk on solidian REMATs. So what is the argument to still use steel or stainless steel? corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer construction materials are required and the service life is increased

Request for a quote

KELTEKS

Croatia

solidian REMATs are produced of our noncorrosive and extremely strong solidian REBARs. The rebars are attached to each other by durable and solid injection molded crossing points forming the rigid mat. As a result, solidian REMATs are combining the same unbelievable mechanical properties of our solidian REBARs with the efficient handling of a robust mat on site. You do not need to knot together with your rebars in your prefab plant or construction site saving time and money. The solid injection points are enabling that you can walk on solidian REMATs. So what is the argument to still use steel or stainless steel? corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic

Request for a quote

KELTEKS

Croatia

solidian REBARs are combining highstrength fibers with extremely resistant resins in the production process named pultrusion. Here carbon or glass fibers are oriented extremely straight, impregnated by resin and hardened. solidian REBARs are realizing unbelievable high and durable loadbearing capacities up to most extreme demands. This is the result of the combination of the straightness of the fibers and the selectable big diameters of the crosssection. As such solidian REBARs are accessible onsite. So they are the ideal noncorrosive substitution for metallic reinforcements for everybody who is interested in economical and ecological sustainability. corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic

Request for a quote

KELTEKS

Croatia

solidian REMATs are produced of our noncorrosive and extremely strong solidian REBARs. The rebars are attached to each other by durable and solid injection molded crossing points forming the rigid mat. As a result, solidian REMATs are combining the same unbelievable mechanical properties of our solidian REBARs with the efficient handling of a robust mat on site. You do not need to knot together with your rebars in your prefab plant or construction site saving time and money. The solid injection points are enabling that you can walk on solidian REMATs. So what is the argument to still use steel or stainless steel? corrosionresistant thinner concrete cover, longer service life, lower refurbishment costs reduced weight with higher tensile strength high tensile strength lower overall construction costs electronically isolating and nonmagnetic sustainable and resourcesaving fewer construction materials are required and the service life is increased

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

For the majority of standard castors, either the tread or the steel bracket is not designed for frequent contact with water or high levels of air humidity or steam. Blickle stainless steel castors, on the other hand, provide corrosion protection in every area, including the high-quality chromium-nickel steel bracket, the synthetic wheel centre, a selection of treads made from rubber, thermoplastic polyurethane and nylon and the various bearings used. This is relevant for wet areas and environments with strict hygiene requirements, such as the food industry.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Various coating and material options play a critical role in ensuring the corrosion resistance of chains. Our product range includes roller chains made of stainless material with zinc plated, nickel plated and galvanized coating. Zinc plating is often used in outdoor environments and prevents the chain from being affected by oxidation and corrosion. Nickel plating is generally preferred in the food and packaging industries; It extends the service life of the chain by creating a protective layer against acid.

Request for a quoteResults for

Corrosion-resistant metals - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Frameworks, concrete (12)

- Domestic waste treatment (3)

- Dustbins, waste bins (3)

- Ceramics, industrial (2)

- Steel & Metals (2)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Doors, sliding and folding - house (1)

- Expanded metal plates (1)

- Machine tools, cutting - parts and accessories (1)

- Pipes and tubes - non-ferrous metal (1)

- Pipes and tubes, stainless steel (1)

- Pumps (1)

- Refrigerants (1)

- Rolling machines (1)

- Wheels, castors and rollers (1)

- Wires and cables - ferrous metal (1)