- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- copper nickel alloys

Results for

Copper nickel alloys - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product Name: Copper Tin Nickel Alloy Width:10-630mm Material:Bronze Grade: Oxygen Free Copper Cu (Min): 75% Model Number:Copper Alloy Place of Origin: China Size: Customised Standard: JIS ASTM DIN EN ISO Certificate: SGS / ROHS / ISO9001:2008 Package: standard export packing Price Term: CIF CFR FOB Ex-Work etc. Usage: Electric Components Lead time:20 Days

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

CuNi3Si alloy with very good bendability, very good hot and cold forming properties, a high strength and a good corrosion resistance. Perfect material for Connectors, bent parts, relays.

Request for a quote

MAGMETT METALL INC.

Turkey

Introducing Master Alloys: The Epitome of Elemental Excellence Crafted with utmost precision and expertise, Master Alloys stand as a testament to the pinnacle of metallurgical innovation. Comprising a harmonious fusion of three fundamental elements - Aluminum, copper, or nickel - these alloys are meticulously blended with a remarkable concentration of other elements, resulting in an unparalleled composition. Master Alloys embody the perfect synergy between the base metals and their complementary counterparts. With a discerning eye for quality, our experts have curated a selection of alloys that showcase exceptional strength, durability, and versatility. Each alloy variant has been carefully engineered to meet the diverse needs of industries ranging from aerospace and automotive to electronics and construction.

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Electroplated metal surfaces are found in all areas of daily life and are used not only for technical purposes but also for decorative ones. For this, metallic coatings made of copper, nickel, nickel alloys, chrome, silver, and gold are used, which can offer both a matte and a high-gloss appearance. The most common application areas for decorative surfaces are found in the automotive industry, in sanitary areas for items such as fittings, but also in the consumer goods industry, thus combining functionality with appealing aesthetics.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

BDSENSORS GMBH

Germany

The pressure transmitter DMK 457 with ceramic sensor has been designed for typical applications in shipbuilding and offshore constructions as alternative to our pressure transmitter DMP 457 with piezoresistive stainless steel sensor. In combination with the copper-nickel-alloy the DMK 457 is suitable for seawater, e.g. level measurement in ballast tanks, etc. Features: — nominal pressure: 0 ... 400 mbar up to 0 ... 600 bar — accuracy: 0.5 % FSO — shipping approvals GL (Germanischer Lloyd), DNV (Det Norske Veritas), CCS (China Classification Society), ABS-certificate (American Bureau of Shipping), LR-certificate (Lloyd´s Register) — pressure port CuNiFe (sea water resistant) — oxygen application Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Q-KUT 170 is specially engineered for medium to heavy-duty machining, grinding, and threading operations that demand a superior level of lubrication. This versatile fluid is well-suited for use on all steel grades, with a particular emphasis on challenging materials like high nickel alloys and copper.

Request for a quote

AXON CABLE SAS

France

Vibraflame® is a range of cables designed to resist extreme temperatures ranging from -196°C to +1565°C.These fire resistant range of cables do not propagate flame and do not contain asbestos. They can be used as control, coaxial or power feed cables. Axon’ offer extension and compensating cables for thermocouples insulated with vibraflame® material and resistant to temperatures of up to 1050°C. These heat resistant cables can be made with nickel plated copper, nickel alloy, nickel chrome, iron, constantan, copper alloy, cupronickel for extension and compensating cable. They are insulated with a special combination of mica, organic polymers and fibre glass. Applications include power and control cables in steel works, oil refinery, electric furnace, blast furnace,etc

Request for a quote

AXON CABLE SAS

France

The range of cables has been designed to avoid propagation of fire and emission of toxic fumes in public places and industrial facilities in case of fire.These Low Smoke Zero Halogen (LSZH) cables and wires can be offered as single wires, shielded cables or multi-core cables jacketed with Axon' special compounds. They are designed to resist temperatures ranging from -50°C to +250°C. LSZH cables offered by axon' are made with tin plated copper, nickel plated copper, copper alloy, or silver plated copper conductor. They are insulated with special halogen free insulating material including Poliax™, Neutrax™, Polyimide, Axon Special Compound. This is an ideal solution for cabling of buildings, trains, subways, ships, industrial premises and all public places where security of people and material have to be assured

Request for a quote

AXON CABLE SAS

France

Axon' offers an extended range of equipment wires and cables for any applications requiring resistance to high temperatures. Different types of constructions can be proposed and delivered ex stock. They are designed to resist high temperatures ranging from -90°C to +260°C depending on the insulation material ; PTFE, ETFE, FEP or polyimide. They are made with silver plated or nickel plated conductor copper alloy, tin, silver or nickel plated copper. They can be used for various applications: aeronautics, automotive, space telecommunications, electronics, military equipment, general industry, ...

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A. S.p.A. has always stood out for its multitechnological capabilities and highperformance manufacturing, efficiently and flexibly carrying out the entire production cycle of each fitting, starting from forging through to the final testing phase and any relevant certifications. STANDARD FITTINGS and UNIONS are high quality products that can be supplied both threaded (according to ASME B1.20.1) and socketweld, as well as SWAGE NIPPLES that are available in all standardised variants threaded, BW, plainend, eccentric. This family of standard products is available in carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and others. The material can be certified NSF 61, NACE, PED, and Norsok.

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

Materials: Body: Copper-Nickel alloy, with 80% of Copper and 20% of Nickel - ISO429 Nail: Austenitic stainless steel (A2) - Aisi304 - X5CrNi18-10 (EN 1.4301).

Request for a quote

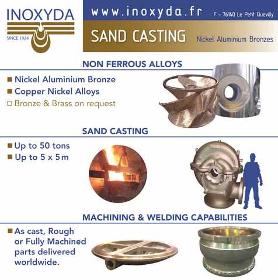

LBI

France

Sand casting of copper alloys, mainly nickel aluminium bronze Maximum weight: 50 tons. Staff: 50 employees. Turnover: approx. 8 M€ 4 et 8 rue Etienne Dolet F-76140 LE PETIT QUEVILLY Tél: +33 (0) 2 35 63 78 50 Fax: +33 (0) 2 35 72 99 99 Internet www.inoxyda.fr E-mail : contact@inoxyda.fr

Request for a quote

M.E.G.A. SPA

Italy

The SPECIAL PRODUCTS section includes all FITTINGS, NOZZLES and SPECIAL FLANGES made to specific customer requirements in the following materials carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and other metals. HEAVY WALL FITTINGS are manufactured from customer specifications, or from accurate design according to the requirements of international codes, including ASME B31.1, B31.3, B31.4, B31.8, ASME B&PV Code Section I, Section III, Section VIII Division 1 and Division 2, PED, RCCM, EN 13480, EN 10253 or others, and is supported by finite element analysis or calculation reports. In this product category, we have special tees (e.g. two, three or more branch outlets), special wyes (two, three or more ways, with piggability requirements), special caps, special flanges (e.g. swivel flanges, anchor flanges) and flanged fittings, and many other types of fittings designed and developed according to specific requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

Cu-Ni 715 is a copper-nickel alloy that is resistant to corrosion in sea water. The alloy has good fatigue strength and relatively high thermal conductivity. This alloy is used mainly for flexible metal foil heaters. The alloy is readily formed in the annealed temper, and can be joined by the standard welding, brazing and soldering processes. Available Sizes: Cu-Ni 715 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.010” (0.0127 mm to 0.254 mm) in widths up to 12” (304.8 mm). The material conforms to ASTM B122 and UNS C71500.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Constantan® is a copper-nickel alloy that contains specific minor amounts of additional elements to achieve precise values for the temperature coefficient of resistivity. Careful control of melting and conversion practices results in a very low level of pinholes at ultra-thin thicknesses. The alloy is used extensively for foil resistors and strain gauges. The TCR can be adjusted from the furnished cold rolled values by using a low temperature heat treatment to achieve compensation for all types of spring elements. The foil is normally supplied with 90% cold reduction and a smooth bright surface. The foil is reasonably flat at 4” wide and nearly free of pinholes. The cold rolled foil can be produced with a TCR between +10 to –35 PPM/°C. The heat treatment will shift the foil TCR to the desired value. A typical heat-treat curve for Constantan® shows decreasing resistivity but increasing TCR with increased heat-treating temperature.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® 400 is a Nickel-Copper alloy with excellent corrosion resistant characteristics in marine environments. The alloy is readily formed from the annealed temper. It is easy to fabricate by conventional welding techniques. Available Sizes: HPM® 400 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.050” (0.0127 mm to 1.27 mm) and widths up to 12.0” (304.8 mm). The material conforms to ASTM B127 and UNS N04400.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in development and production of technical high performance alloys components : copper alloys, nickel alloys, but also aluminium alloys, specialty steels, stainless steels, titanium and nickel supperalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Hamilton Precision Metals is the world leader of precision-rolled foil and ultra-light gauge strip in any alloy. This includes stainless steel foil, titanium foil, nickel foil, copper based foil, cobalt based foil, Constantan® foil, Evanohm® foil, and many other alloys. Metal foil is generally defined as strip 0.004” (0.1016 mm) and below. Cold rolling strip to these extremely thin gauges demands extensive rolling expertise to manufacture with precision and consistency. Foil in Any Alloy We offer the broadest portfolio of almost every high performance alloy made today. Additional alloys are available upon request, contact us today! Stainless Steels Nickel Based Alloys Copper Based Alloys Cobalt Based Alloys Commercially Pure Titaniums Strain Gage: Constantan®, Evanohm®, Tightest Tolerances and Thinnest Gauges in the Industry We custom roll metal foil in nearly any alloy and specialty metal to the tightest tolerances and thinnest gauges

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products.

Request for a quoteResults for

Copper nickel alloys - Import exportNumber of results

94 ProductsCountries

Category

- Copper and copper alloys (49)

- Steels, nickel (14)

- Foundries - copper, bronze and brass (10)

- Steel & Metals (9)

- Cold rolled steel strips (3)

- Electric cables (3)

- Nickel plating (3)

- Copper wires and cables (2)

- Pipe and tube fittings - ferrous metal (2)

- Stainless steels (2)

- Tools & Hardware (2)

- Aluminium and aluminium alloys (1)

- Brass (1)

- Brazing - equipment and supplies (1)

- Chemicals - Basic Products & Derivatives (1)

- Greases, industrial (1)

- Hand tools, non-power (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Pipes and tubes, copper (1)