- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coolant pumps

Results for

Coolant pumps - Import export

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Immersion pumps series TH and FH use closed impellers in order to minimize power consumption and to optimize hydraulic pump efficiencies.In addition, the TH series offers high pressures at short immersion depths. Inline pumps of the series FH can be used as boostingpumps if provided with positive inlet pressure. This inlet pressure can be provided by the central coolant supply or a feed pump. In such a setup, pumps of the series FH can raise the incoming pressure by up to 26 bar. Extended length is possible. See mechanical/hydraulic features within the technical information section. Volumetric delivery: up to 640 l/min Delivery head: up to 520 m Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Immersion Pumps are plain centrifugal pumps with the impeller fitted on the driving shaft extension. They are mounted on top of the container, the pump extension being immersed in the coolant. The maximum coolant level must stay a few mm/inches below the mounting flange. The STA serie offers a (SAE) flange with pressure gauge connection port. The flange can be rotated for either horizontal or vertical pipe connections. Volumetric delivery: up to 5000 l/min Delivery head: up to 120 m Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Pressure Boosting Pumps series TH and FH use closed impellers in order to minimize power consumption and to optimize hydraulic pump efficiencies. In addition, the TH series offers high pressures at short immersion depths. Inline pumps of the series FH can be used as boosting pumps if provided with positive inlet pressure. This inlet pressure can be provided by the central coolant supply or a feed pump. In such a setup, pumps of the series FH can raise the incoming pressure by up to 26 bar. A frequency converter can be supplied for special applications or for matching the pump characteristic to a specific duty point. See page "Control/Regulation" in the Technical Information Volumetric delivery: up to 640 l/min Delivery head: up to 520 m Horizontal cutter pumps

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Quick Suctioning Immersion Pumpsseries TGL/SGL equipped with the patented "BRINKMANN`s Suction De-aeration System" are excellently suited to pumping extremely inflated fluids (grinding oils) as they occur in high-speed grinding. The quick suctioning immersion pumps reach stable working conditions as soon as the liquid level reaches the suction inlet. The SGL serie offers a flange with pressure gauge connection port. The flange can be rotated for either horizontal or vertical pipe connections. Volumetric delivery: up to 2600 l/min Delivery head: up to 88 m Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are self-priming after initial filling. All pumps are equipped with a single mechanical seal. SBM Pumps are mounted next to or on top of the tank and they are suitable for pumping air entrained coolant fluids, such as water-soluble coolants or cutting oils, as they occur in high speed turning, milling or grinding applications. Volumetric delivery: up to 440 l/min Delivery head: up to 20 m Please contact us for delivery quantity.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are not self-priming and must be gravity fed. All pumps are equipped with a single mechanical seal. Upon request a second mechanical seal is available to allow for dry-running (-GD). This pump series is designed for horizontal installations next to a tank and for pumping air entrained coolant fluids, such as water-soluble coolants or cutting oils, as they occur in high speed turning, milling or grinding applications. The SBA pumps are equipped with the user-friendly (SAE) flange connection which allows for either vertical or horizontal pipe connection and the connection of a pressure gauge with G 1/4. Volumetric delivery: up to 2200 l/min Delivery head: up to 62 m Please contact us for delivery quantity.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Quick suctioning immersion pumps series SFL equipped with the patented "BRINKMANN's Suction De-aeration System" are excellently suited to pumping extremely inflated fluids (emulsions) with heavy chip loads as they occur in heavy cutting when turning, milling or grinding. The quick suctioning immersion pumps reach stable working conditions as soon as the liquid level reaches the suction inlet. The SFL serie offers a flange with pressure gauge connection port. The flange can be rotated for either horizontal or vertical pipe connections. Volumetric delivery: up to 2500 l/min Delivery head: up to 46 m Please contact us for delivery quantity

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

PRESSTA EISELE GMBH

Germany

A double head mitre saw with disappearing blades specifically studied for the tubular steel shapes. Automatic positioning of the movable unit. Electronic positioning of the cutting units on any angle within 45° and 135°. It is equipped with the system TS 690. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Speed of rotation of the blades, variable by means of a frequency converter (inverter). Automatic shifting of the support plates of the profile once over the cutting cycle. Dynamic protection guards for a total covering of the cutting area. Blade lubrication cooling system with electric pump. Coolant liquid vat with extractable pump for vat cleaning. Cutting deepth stop device. Intermediate workpiece support automatically operating Mobile roller conveyor with pneumatic clamp for section support Compressed air treatment unit (filter/reducer/lubricator)

Request for a quote

APD MAQMASTER

Spain

1. The T 250-S reinforcement saw is equipped with a head that can rotate both to the right and to the left; 2. Oil bath gearbox with membrane coolant pump; 3. Filter for coolant and vise complete with anti-drip device; 4. Equipped with a 24 Volt low voltage system with control directly on the handle.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures.Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Free Flow-Immersion Pumps series SFT are designed to lift coolant for filtering. Coarse shreds can be transported together with liquids. The SFT serie offers a flange with pressure gauge connection port. The flange can be rotated for either horizontal or vertical pipe connections. Impellers: semi-open Fluids: coolants, emulsions, oils Volumetric delivery: up to 2350 l/min Delivery head: up to 28 m Examples of applications: — Water based coolant and chips — Pump back system — Pump back for various chip materials Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Free Flow-Immersion Pumps series FT/FTA are provided to lift coolant for filtering. Middle shreds can be transported together with liquids. Impellers: semi-open Fluids: coolants, emulsions, oils Volumetric delivery: up to 200 l/min Delivery head: up to 6,5 m Examples of applications: — Water based coolant and chips — Pump back system — Pump back for various chip materials Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Immersion Pumps Models TS12 to TS24 are suitable for CNC machine tools featuring coolant supply through the tool holder or driving spindle or equipped with internally cooled tool. These pumps are equipped with a peripheral impeller to achieve a compact high pressure unit. Series TS are suitable for filtered coolant only. To reduce pump pressure, models TS22 to TS24 are also available with an optional Y/YY (Dahlander) motor configuration for 4 pole operation at half speed. Volumetric delivery: up to 70 l/min Delivery head: up to 95 m Please contact us for delivery quantity

Request for a quote

PROSAW LIMITED

United Kingdom

Bomar Ergonomic 275.230DG Standard Details: Heavy duty one-piece cast bow Precision control hydraulic downfeed Substantial vices, quick set lever operation Bow rotates 45-90-60° Easy to read mitre scale Carbide blade guide pads and rollers Heavy duty blade tensioning unit Heavy duty, 3 phase motor Re-circulating coolant pump Adjustable guide arm Heavy duty gear train Blade speed: 35 & 70 m/min 500mm length stop included

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PHILLIPS & TEMRO INDUSTRIES EUROPE

Belgium

The Aqualine v2 is a heating and circulating unit for stall drinking bowls. It ensures the supply of temperate drinking water in winter time and prevents the water from freezing in the bowls. Water temperature is a determining factor for the transformation of food into energy. Cattle always prefer warm water. For example, to heat 50 liters of water of 0°C to 39°C, the animal will spend 1950 calories, which is approximately the third of its daily needs. It can be connected to any drinking bowl line for cows, calves, sheep, pigs, horses, etc. The Aqualine v2 can be supplied in 3 versions : without control box, with control box or with digital control box. Advantages: Very strong heating body made in aluminium with coating Abcite , 100% recyclable Low watt density heating element made of Incoloy 800 (7,5W / cm²) what increases its lifetime and those of the coolant Integrated circulation pump into the heating body allowing a fast and homogenous preheating. ...

Request for a quote

PHILLIPS & TEMRO INDUSTRIES EUROPE

Belgium

(With or without control box) The TopStart H 4-12 kW is an electric coolant heater big size water-cooled engines. The heater can be put into service a few hours before starting the engine or work continuously in order to keep the engine permanently at the required temperature. This ensures an easy full power start whatever the ambient temperature and avoids cold start mechanical damage. The system has the following advantages: fuel savings, decreasing pollution, reduced engine wear, no more difficult cold starts. It is universal, reliable, easy-to-install and maintenance free. Download the technical sheet Download the technical sheet Advantages: Strong die-casted aluminium body, 100% recyclable Low watt density heating element made of Incoloy 800 (7,5W / cm²) what increases its lifetime and those of the coolant Integrated circulation pump into the heating body allowing a fast and homogenous preheating. Very compact product suitable for many different places Adjustable thermostat 0-

Request for a quote

PHILLIPS & TEMRO INDUSTRIES EUROPE

Belgium

The TopStart 0.5 – 4Kw is an electric coolant heater for all types of water-cooled engines. The heater can be put into service a few hours before starting the engine or work continuously in order to keep the engine permanently at the required temperatur. This ensures an easy full power start whatever the ambient temperature and avoids cold start mechanical damage. The system has the following advantages: fuel savings, decreasing pollution, reduced engine wear, no more difficult cold starts. It is universal, reliable, easy-to-install and maintenance free. The TopStart heaters are suited for all industrial applications, either stationary (generator sets) or mobile (emergency vehicles, trucks, vans, etc.). Download the technical sheet Advantages: Strong die-casted aluminium body, 100% recyclable Low watt density heating element made of Incoloy 800 (7,5W / cm²) what increases its lifetime and those of the coolant Integrated circulation pump into the heating body allowing a fast and homo

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

Up to 50% Coolant Saving Up to 90% Saving in Disposal Improved price for swarf without coolant Improved Housekeeping The Wogaard Coolant Saver collects the cutting-fluid that is normally wasted through the machine tools automatic chip conveyor. The cutting fluid is reclaimed from the chip-container and returned to the machine tool's main tank for re-use. Wogaard can help reduce consumption of cutting fluid and water, reduce the amount of waste fluid collected and disposed of and end fluid leaks that create potential health and safety issues. The Wogaard Coolant Saver is easy to install and is virtually maintenance free. It is driven by the machine tool's onboard coolant pump, so no external energy source is required. Building on the success of the Coolant Saver, Wogaard now also produce an Oil Saver for liquids up to 32 centistokes viscosity. This is recommended for sliding head machines and can be used in any application where neat oil is used.

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Chucker Lathe; 1" (25 mm) bar, 4.95" (126 mm) swing over table, 12" x 8" (305 x 203 mm) travels (xz), 5 hp (3.7 kW) 6000 rpm, 5C collet spindle, auto air collet closer, spindle orientation, coolant pump, 15" color LCD monitor, USB port, memory lock keyswitch, and rigid tapping. Shipping Dimensions

Request for a quote

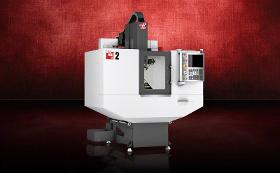

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 20" x 16" x 14" (508 x 406 x 356 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, 20-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, 15" color LCD monitor, memory lock keyswitch, USB port and work light. MINIMILL2 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

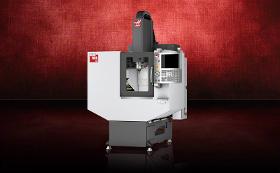

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, 10-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port. MINIMILL Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center for Education; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 4000 rpm, 300 ipm rapids, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor, and USB port. Does not include a tool changer or coolant pump. Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

CNC Toolroom Lathe; 16" x 30" (406 x 762 mm) max capacity, chip enclosure, 20" (508 mm) swing, 10 hp (7,5 kW) vector drive, 1800 rpm, A2-6 spindle, Visual Programming System, coolant pump, 1 GB program memory, memory lock keyswitch, air blow gun, 15" color LCD monitor and USB port. No workholding, toolpost, or toolholders included. TL-1 Dimensions Shipping Dimensions

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Compact Mill; 12" x 10" x 12" (305 x 254 x 305 mm), ISO 20 taper, 5 hp (3.7 kW) vector drive, 30,000 rpm, 20-station automatic tool changer, coolant pump, high-speed machining, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor, and USB port CM-1 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 15 hp (11.2 kW) vector drive, 10,000 rpm, 1200 ipm (30.5 m/min) rapids, high-speed 10-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, and rigid tapping. Three-phase power only. SMINIMILL Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure for vibration-free performance. Adjustable slideways for wheelhead infeed and workhead traverse. Wheelhead Box type monobloc noted for its excellent vibration dampening characteristics. The precision motor grinding spindle is permanently sealed and lubricated. Workhead Located on a swivel plate which can be set to the required angular position by means of a wide-spaced scale. Collets for perfect valve alignment. Dressing Attachment The dressing attachment is permanently mounted on the worktable for rapid wheel dressing. Wet Grinding Coolant is delivered by an industrial type flood pump. The baffled coolant tank is easily removed from the machine base for cleaning. Electrical System Individual grinding spindle motor, work spindle motor and coolant pump motor all controlled by switches grouped in front of the wheelhead for ease of operation.

Request for a quoteResults for

Coolant pumps - Import exportNumber of results

35 ProductsCompany type

Category

- Pumps (13)

- Cooling and lubrication pumps (8)

- Paint mixers and grinding machines (4)

- Submersible pumps (3)

- Centrifugal pumps (1)

- Forming - steels and metals (1)

- Machine tools - metal machining (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Oil filters (1)

- Sawing machine tools (1)