- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyor system design

Results for

Conveyor system design - Import export

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Steel construction, metal, etc. with a high production capacity. It is the type of sandblasting machine preferred by companies in the production sector. The conveyor system is designed as trolleys carrying hanger hooks on a linear line. Different conveyor types are preferred according to light and heavy materials.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

Open conveyor systems are susceptible to contamination from foreign objects or small components, which can lead to potential belt failures or damage to the items being transported. Transfer chains designed for conveyor systems act as a preventative measure, preventing costly breakdowns before they occur. These Transfer (TF) chains are completely sealed on three sides thanks to wear-resistant, durable snap-on plastic attachments. These attachments maintain coverage even when the chains pass over the sprockets.

Request for a quote

ILK IHRACAT AS.

Turkey

Our conveyor systems are designed to be the heart of Industry 4.0, the fourth industrial revolution that is transforming the manufacturing landscape. Industry 4.0 is characterized by the integration of digital technologies and automation into the manufacturing process, resulting in increased efficiency, improved productivity, and reduced costs. Our conveyor systems are at the forefront of this revolution, incorporating advanced technologies such as Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML). These technologies enable our conveyor systems to collect and analyze real-time data, optimize production processes, and make intelligent decisions. With IoT capabilities, our conveyor systems can communicate with other machines and systems in the production line, creating a seamless and interconnected network. This allows for real-time monitoring and control, ensuring that any issues or bottlenecks are quickly identified and addressed.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A cement and filler elevator is an integral part of a vertical conveyor system, specially designed for the movement of cement, fillers, and other powder materials in a number of industrial contexts. These elevators find application in many industries where the bulk materials need to be moved vertically, like in cement plants and concrete batching plants at construction job sites. Using a number of attached buckets or compartments to a belt or self-supported chain, the elevator efficiently raises the materials from one level to another within the production or storage area, streamlining the process and improving overall workflow. A cement and filler elevator is designed considering such aspects as durability and efficiency. The system has been structured to hold heavy loads that are characteristic of cement and filler materials; this ensures that materials are delivered to their destinations with success and without any disruption.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Skipper Conveyor is probably the most novel and technological advancement attributed to conveyor systems meant to streamline handling and distribution exhaustively used across a wide array of industries. Unlike the traditional style of conveyor systems, Skipper Conveyors are designed with diverter chutes or gates along the conveyor line. These chutes can be actuated to selectively direct materials to diverse discharge points or processing areas based on stipulated criteria such as size, weight, or destination. The capability of selectively distributing therefore makes Skipper Conveyors very useful; for instance, the separation and the direction of materials to many various stages of the production process are needed. An automated control system can also be integrated into the design of a Skipper Conveyor, which can control a diverter chute based on real-time data or according to an instruction that has already been programmed.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Skipper Conveyor is probably the most novel and technological advancement attributed to conveyor systems meant to streamline handling and distribution exhaustively used across a wide array of industries. Unlike the traditional style of conveyor systems, Skipper Conveyors are designed with diverter chutes or gates along the conveyor line. These chutes can be actuated to selectively direct materials to diverse discharge points or processing areas based on stipulated criteria such as size, weight, or destination. The capability of selectively distributing therefore makes Skipper Conveyors very useful; for instance, the separation and the direction of materials to many various stages of the production process are needed. An automated control system can also be integrated into the design of a Skipper Conveyor, which can control a diverter chute based on real-time data or according to an instruction that has already been programmed.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Cement and Filler Elevator? A cement and filler elevator is an integral part of a vertical conveyor system, specially designed for the movement of cement, fillers, and other powder materials in a number of industrial contexts. These elevators find application in many industries where the bulk materials need to be moved vertically, like in cement plants and concrete batching plants at construction job sites. Using a number of attached buckets or compartments to a belt or self-supported chain, the elevator efficiently raises the materials from one level to another within the production or storage area, streamlining the process and improving overall workflow. A cement and filler elevator is designed considering such aspects as durability and efficiency. The system has been structured to hold heavy loads that are characteristic of cement and filler materials; this ensures that materials are delivered to their destinations with success and without any disruption.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

What is a Twin Bucket Chain Elevator? A twin bucket chain elevator can be described as a specially designed vertical conveyor system whereby it can transport bulk materials, such as grains, sand, ore, coal, and others that are granular or in powdered states. Consider this kind of elevator with two parallel chains or belts fitted with a series of buckets running in a continuous loop. In operation, the elevator scoops up material at the lower end with its buckets and transports it to the top for discharge. This mechanism ensures an effective and controlled way of moving large quantities of bulk materials vertically. These elevators find wide applications in industries where bulk material handling is a crucial aspect of the operation, like in agriculture, mining, construction, and manufacturing. This system comes into its own in applications that involve dependable, continuous material flow between various levels in a facility.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

The screw conveyor is system designed to transportation of loose bulk product from one place to another,alternatively used for waste treatment(shells,peels)loading and unloading the transportation vehicles or silos. The product moves up forward by means of spiral wings in the pipe; When the product reaches to the exit point, products discharged down from the spiral eject point.Using multiple discharge points,screw conveyors efficiently distribute bulk materials to different areas.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Volumetric filling system SCADA and HMI with a touch screen system 2 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system UV sterilizer system Servo conveyor system Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 1 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 2 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system UV sterilizer system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 1 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

RIGA WOOD GMBH

Germany

Machinery production and metal processing Services: Production of large size components CNC machining Designing, production and installation of non standard technological devices Log feeding and sorting line design, production and installation Wooden by-products and biomass feeding conveyor system design and production Additional information: www.iekarturupnica.lv

Request for a quote

BENG ROBOT TEKNOLOJILERI A.S.

Turkey

We can design special conveyor systems for your needs with / without a robot inside.

Request for a quote

GSW SCHWABE AG

Germany

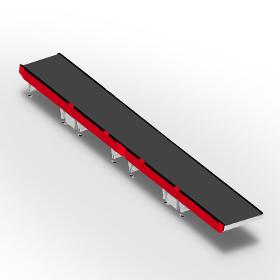

with its compact design using a structural aluminum profile, conveyor system is ideally suited for continuous duty applications in multiple shift environments. using the benefits of modular construction, this conveyor can be readily integrated into new or existing equipment or be used as a freestanding conveyor for bulk handling and loading aplpications. inclination smoothly adjustable steplessly fourwheel drive, 2 steering wheels with parking brake 13 collector rollers, height 20 mm transport cover PUeven, 2 layers, to be used at temperatures from 30 120°C, oiland grease resistant, antistatic funnel (attachment), aluminium anodized drop area pivotable clip/aluminiumclosed bar system suitable for materials to be conveyed from a thickness of 2 mm on for lower thicknesses of materials to be conveyed, allaround corrugated material edges made from celloflex. This reduces the usable width of the material by approx. 70 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HO-MA GMBH

Germany

Its flexible design makes the flush-grid belt conveyor particularly compact and its curve radius can be adjusted.

Request for a quote

TOMECH SOLUTIONS

Romania

Conveyors are mechanical devices used to transport materials from one place to another within a facility or between different locations. They are integral to numerous industries, including manufacturing, logistics, and transportation. Types of conveyors include: belt conveyors, roller conveyors, screw conveyors, chain conveyors, gravity conveyors, bucket conveyors. We specialize in conveyor design services, tailoring solutions to meet the unique needs of our clients. Our expertise covers the design, optimization, and implementation of conveyor systems to enhance efficiency, productivity, and safety in diverse industrial settings.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt offers a range of straight conveyors designed to ensure efficient operation, improved belt life and maximum cleaning ability. Our straight conveyors feature an open construction with the belt being supported on food grade high density blue polyethylene wear strips clipped to the stainless steel framework. All of our conveyors are suitable for use in hygiene-sensitive environments common to the food and pharmaceutical industries.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

The necessity to spread/separate or converge products while they are moving on a process belt conveyor is a major requirement for a wide range of food, confectionery and industrial applications. In many cases this allows processors to run narrower conveyors saving factory floor space. Coating processes also benefit by separating product and reducing rejection rates.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Motion06 Manual Sorting Belt Conveyor is used in those places where bulky luggage is collected centrally from the various luggage lines and prepared for inspection. As a special solution, it can be adjusted to a huge range of conditions, such as conveyor height, positioning of the control system, belt lengths, conveying direction or conveying speed. The heart of the sorting belt is formed by two plastic link conveyors, which are characterised by a very smooth and wearresistant surface and have a far longer life span than roller tables that have been used in the past. The individual pieces of luggage are transported to a certain position by the electronic link conveyor and then manually pushed off in the direction of the conveyor. This procedure makes the work of airport personnel considerably easier.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

With a capacity of up to 2500 pieces of baggage per hour, strength and resilience are fundamental. The Motion06 Vertical Sorting Unit Belt Conveyor is used for the distribution and merging of baggage and general cargo between two or three levels. The belt conveyor incorporated into the Vertical Sorting Unit is height adjusting using a top of the line lifting system with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. It is also possible to use it in flight baggage systems with a container system. The belt conveyor is replaced by an appropriate conveyor element for this purpose. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

An innovative new design to allow you to easily sort packages and parcels during your manual sortation process. The unit can also be supplied with an integrated weight scale unit with a digital display. Adjustable Height Telescopic leg sections to raise or lower the conveyor bed height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. Castors with Brakes 127mm x 38mm Swivel Castors allow easy movement. Castor brakes lock both wheels and swivel simultaneously while the conveyor is in use.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestConnect system is designed to provide rapid assembly of conveyor solutions for changing workplaces. Systems can be easily configured and reconfigured as required to suit your immediate requirements. With a simple 240v power supply and latching connections, the engineering requirement is minimal. Continuous Duty Multiple Drive Motors 20 to 120 Vdc geared motors. Adjustable speed is from 2 to 36 metres per minute. Start/ Stop controls at both ends. Adjustable Height Telescopic legs to raise or lower the conveyor height. Square Tubing Legs Heavyduty square tubing legs offer longer service life and stability. 50mm Roller Heavyduty precision bearing rollers on 12mm axles for greater durability.

Request for a quote

TIKIR MACHINE INDUSTRY

Turkey

200 meters metal scrap conveyor. It was designed, manufactured and assembled by Tıkır Makina by the world-famous oven manufacturer company, together with 10 pant chutes and one rotary chute. It was commissioned in 2021. The scrap conveyor, which allows the scraps coming out of the presses to flow to the line through pant chutes, fill the baskets at certain points beforehand through the rotary chute. While the scrap conveyor works effectively in this way, it provides efficiency, time savings and safety. The scrap conveyor occupies a very important place especially in the metal processing industry. However, it is possible to design suitable for all sectors. Apart from scrap conveyor, we can produce belt conveyors, pallet conveyors, chain conveyors and roller conveyors. We are waiting for you. Contact us.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The MaxxReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction MaxxReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction BestReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quoteResults for

Conveyor system design - Import exportNumber of results

60 ProductsCountries

Company type

Category

- Conveyor systems (41)

- Conveyor belts (7)

- Concrete preparing - machinery and equipment (3)

- Food industry - machinery and equipment (3)

- Tar and asphalt - construction materials (2)

- Bottling and filling - machinery and equipment (1)

- Engineering - industrial consultants (1)

- Erection and dismantling of industrial plants (1)

- Food canning and preserving - machinery and equipment (1)

- Grids, gratings and wire mesh (1)

- Machine tools, cutting - parts and accessories (1)

- Machine tools, metal shaping - parts and accessories (1)

- Plastics - machines and material for industry (1)

- Sandblasting equipment (1)