- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyor stop

Results for

Conveyor stop - Import export

AVM AUTOMATION

France

This retractable stop is drived by a double-acting pneumatic cylinder. It is retracted by a 90° rotation of the finger in the direction of movement of the pallet or the object to be stopped. When it is engaged to stop the moving element, it is mechanically locked by a toggle joint action which ensures high repeatability of this stop (<0.05 mm with mechanical stop). There are 3 common applications for this retractable stop: • Create a conveyor stop, a stop pallet, a separating stop, a stopper cylinder • Create an intermediate position for a manipulator or a linear pneumatic gantry • Referencing a product on a workstation

Request for a quote

BIZERBA SE & CO. KG

Germany

Quick and reliable detection of all ferrous and non-ferrous metals in packaged and unpackaged piece goods. The compact metal detection system offers you safe performance and highest detection sensitivity. With its robust stainless steel conveyor belt construction the VARICON+ inspects piece goods of up to 50 kg. A very short metal-free zone (MZ) ensures interference-resistant, reliable inline metal detection. To suit the area of installation the system is available with a modular belt (wet area) or a flat belt (dry area). The conveyor belts are available with variable belt widths. The motor controller is fitted either with a conveyor stop in case of metal detection or an application-specific rejection system. For easy and thorough cleaning the VARICON+ series has a hygienic design. Quality which is reflected in BRC, IFS and HACCP certifications. The VARICON+ comes with IP65 protection. Higher IP ratings are optionally available.

Request for a quote

PRESSTA EISELE GMBH

Germany

Helping hand: Lifter for placing profiles on roller tracks or loading magazines. Pneumatic lifting and feeding of profile bars by conveyor belt Adjustable stops to place the bar to correct position. Function: The bar is pushed against a contact surface – the bar lift up automatically and feed to load. Automatic lowering when position is reached. Belt speed: 9m/min Belt dimension: width 50mm, length 1400mm Lifting stroke: 250 – 1350mm adjustable Max. Profile weight: 90 kg

Request for a quote

FERPLAST SNC

Italy

PNEUMATIC TURNING DEVICE WITH FREE ROLLERS 90F MODEL. DIVERT BOXES BY 90°. Pneumatic turning device with free rollers conveyor, complete of stop barrier including sensor and pneumatic pusher with cylinder of 50 mm for expulsion of boxes at 90°. The metal structure is painted while the other components is provided with galvanized finish. The pneumatic pusher is activated by a box hitting the stop barrier, changing its direction of 90°. Usually it used in cascading lines.

Request for a quote

FERPLAST SNC

Italy

PNEUMATIC CENTERING DEVICE WITH MOTORIZED ROLLERS (MOD. CP-FM) MANUFACTURERS VERSION Feeder - centering device useful for centering boxes max width mm. 650 and max weight kg. 50. Can be combined with automatic taping and labeling machines. The box centering machine mod. CP-FM consists of a motorized roller conveyor and two pneumatically operated side guides. The metal parts are painted with epoxy powder while the other components are galvanized. The pneumatic centering device with motorized rollers is a module for builders to be completed and adapted to an automatic line. It is available in two versions: Manufacturers version and "plug and play" version: In the "manufacturers" version, the centering device is supplied complete with: - Motorized roller conveyor with start and stop button and emergency mushroom, at a fixed speed of 15 meters / minute - Pneumatic tail lifts and compressed air system up to the gate movement management valve.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Your Solution for Efficient Material Handling The Tubular Drag Conveyor ensures that materials are transported gently, with en masse movement limiting turbulence, reducing wear and tear. Operating with high torque at low speeds, means it is remarkably energy-efficient while delivering the robust, dependable performance you need. As such, a minimal fraction of the product grazes the pipe walls, diminishing the chance of abrasive degradation. Robust and versatile, our conveyor is capable of stopping and restarting even when fully loaded. Such a feature saves time and prevents wastage, allowing for a seamless operation during unexpected halts or necessary pauses in the workflow. While the completely enclosed, dust-tight design is crafted for industries challenged by the management of dusty, smelly, toxic, or hazardous materials.

Request for a quote

AVM AUTOMATION

France

Pneumatic retractable stop Locking by toggle joint action Adjustable stop screw Operating principle of the retractable stop This retractable stop is drived by a doubleacting pneumatic cylinder. It is retracted by a 90 ° rotation of the finger. When it is engaged to stop the moving element, it is mechanically locked by a toggle joint action. The retractable finger supports an impact force of 2250 N or less, it is generally necessary to provide damping at the point of contact (elastic or hydraulic depending on the application). Detection by 2 inductive Ø8 detectors is optional. Using of the retractable pneumatic stop There are 3 common applications for this retractable stop • Create an intermediate position for a manipulator or a linear pneumatic gantry • Create a conveyor stop • Referencing a product on a workstation For an intermediate position of the pneumatic manipulator, a hydraulic shock absorber must be placed opposite the stop screw.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

The logic functions provide a secured and controlled flow of goods on the conveyor line by starting and stopping at defined segments with in a conveyorline. The logic functions control the accumulation roller convenyor with precise insertion and removal of goods during distribution

Request for a quote

NANOSYSTEC GMBH

Germany

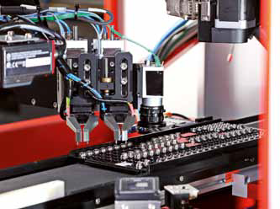

The fully automated assembly station VersaGlue takes components, such as lenses or dies from a loading area and mounts them by epoxy gluing with UV or thermal curing. The large work area of up to 1000 mm x 1000 mm provides space for the positioning of device trays and support systems. The parts are presented manually or fully automated. Feeders or stop-motion conveyor belts bring the parts to the working area and collect the finished product. The VersaGlue processes optoelectronic elements like VCSELs, photo diodes, laser dies and micro optics with highest precision while the passive placement of fiber ribbon cables is another major application.Thorough design and continuous optimization of all functional groups lead to superior mechanical stability. Mechanical references with tight tolerances provide a repeatable manufacturing operation from device to device.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION It is computerized conveyor which helps to cut the glazing bead profiles specially in the required measurements precisely Self- positioning of the conveyor stop according to the values entered on the digital screen It is ideal for cutting glazing bead profiles precisely 5.5 touch screen control panel Preparation of cutting lists on the control panel Possibility of manual or automatic operation Easy assembly on sawing and copy router machine without conveyor Digital measuring rod :1.5 m (SKN 301) - 2 m(SKN 451)- 3 m (SKN 601) Obtains data from wireless measurement reader Pieces are cut in the order according to the measurement data that is sent from the digital measuring rod OPTIONAL ACCESSORIES Sizes could be customize according to requirements. Videolar TECHNICAL SPECIFICATIONS 250 W 230V AC 50~60 Hz 3000 RPM 58x315x56 cm 157 kg. 97 kg.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION CK 412 is an automatic saw blade machine which is ideal for cutting operations of the PVC glazing beads at 45°. Adjustable saw blade feeding speed Pneumatic saw feed by pushing button Equipped with 2x pneumatic vertical clamps Automatic return to start point of the process Twin blade design 8 glazing beads can be cut simultaneously using single mold without problems STANDARD ACCESSORIES 1x Ø 200 and 1x Ø 103 mm saw blades KN 152 roller conveyor Air gun OPTIONAL ACCESSORIES Clamping device for special glazing beads Additional saw blades Digital Roller Conveyor with Automatic Stop (SKN 301) SKN 300, SKN 450,SKN 600 conveyor SKN 301, SKN 451, SKN 601 conveyor Videolar TECHNICAL SPECIFICATIONS 1200 W x2 400V AC 50~60 Hz 3.000 D/dak. RPM D1:103 mm D2:200 mm d:30-32 mm 6~8 Bar 35 Lt. / dak. 54x113x124 cm 168 kg 134 kg

Request for a quote

TAMPOPRINT GMBH

Germany

Die ROTOPRINT ist zur Verschlusskappenbedruckung die wirtschaftlichste Lösung mit höchsten Qualitätsmerkmalen bei maximaler Leistung. The ROTOPRINT can be equipped for printed images with between one and three colors. Depending on equipment, the concept enables an output of max. 3000 printed bottle caps/min. (28 mm diameter). With all variants, products are supplied using the tried and tested ascending conveyor. This prevents unnecessary machine stops caused by incorrectly oriented caps. All 3-lane ROTOPRINT machines are supplied with a water-cooled wheel in their basic equipment. Outstanding register accuracy is attained by the constant temperature of the jig carrier. Together with the H-RTI 21-150 printing unit, sophisticated motifs with precise print images for years to come and consistent quality are attained. Rapid color, cliché and motif changes and simple and tool-free operation reduce the ROTOPRINT‘s tooling times.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The MaxxReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction MaxxReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction BestReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The Mobile Loader is designed specifically for use in premises without a raised loading dock, which makes it ideal for loading vans and other smaller vehicles. Using this unit makes your vehicle loading/unloading operation faster, safer and more efficient, and helps you comply with manual handling regulations. Construction Heavyduty construction and supporting framework make Mobile Loaders one of the most robust units of its type on the market. Shrouded Buttons To limit the damage to emergency stops, FMH Conveyors add fabricated steel shrouds to the exposed emergency stop buttons. Fully Guarded All moving or rotating parts are fully guarded to prevent entrapment and injury. Mobile Mobile Loader units are fully mobile utilising 200mm heavy duty castors.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

SV Loader units are designed to load small vehicles from either level access or dock levellers. Ideally suited for the parcel, postal and 3PL markets, this unit is easy to use and can be combined with our BestFlex, PowerFlex or BestConnect to create a total loading solution. Construction Heavyduty construction and supporting framework make Mobile Loaders one of the most robust units of its type on the market. Shrouded Buttons To limit the damage to emergency stops, FMH Conveyors add fabricated steel shrouds to the exposed emergency stop buttons. Fully Guarded All moving or rotating parts are fully guarded to prevent entrapment and injury. Mobile Mobile Loader units are fully mobile utilising 200mm heavy duty castors. Power Mobile Loaders are normally powered via a simple 240Vac plug connection. 110Vac and 415Vac versions are available. Each unit comes with ancillary sockets to power adjoining flexible conveyors.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Pull cords are used as actuators for operating pull rope emergency stop switches along conveyor belt systems. The pull cord and the accessories required for installation are functionally matched to the pull rope emergency stop switch, taking normative requirements into account. We therefore constantly carry out Pull cord, steel cable, 3mm or 5mm red PVC sheathed Various types of tension springs Anchor hook M10 Anchor hook M12 Anchor hook M8 Turnbuckle M6; 2 eyelets Turnbuckle M6; 1 hook / 1 eye Chain link 6 Eye bolt M12x60 * Eye bolt M12x200 * Eye bolt M12x60 * Clamp bracket, size. 3 5 Clamp egg shaped, size. 3 Clamp egg shaped, size. 5 Thimble Gr. 3 Thimble Gr. 5 Marking plate for rip cord Deflection pulley M10x60, pulley And much more

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Conveyor stop - Import exportNumber of results

17 ProductsCountries

Company type

Category

- Conveyor systems (6)

- Automation - systems and equipment (1)

- Bearings - ball, needle and roller (1)

- Conveyor belts (1)

- Goods handling systems, continuous (1)

- Import-export - electrical and electronic equipment (1)

- Metal detectors (1)

- Pad printing (1)

- Pneumatic conveyor equipment (1)

- Pneumatic systems and tools (1)