- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- control process components

Results for

Control process components - Import export

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

Two modern AOI devices (automatic optical inspection) in 2D and 3D secure the manufacturing process during the SMT assembly. We use our X-ray inspection device to control the soldering process on components with connections under the housing. In addition to quality assurance, we also offer test and inspection procedures that are precisely tailored to your needs. In addition to circuit-specific in-circuit and burn-in tests, we can carry out application-related function tests in our test field. For specific tests, many customers send us the test procedures with the appropriate equipment directly. In this way we can check the functionality of your assembly without you having to tell us what exactly the tests are checking. Your advantages with A + B Electronic -Test procedures tailored to your needs -We are not just a service provider, we are a technology partner: A + B Electronic thinks your project with you and together we can successfully bring it into series production

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Absolute operating principle with magnetic signal sensing via two read heads. Extremely insensitive to oil, moisture and dust due to magnetic signal sensing. Large inner diameters of 96mm or 180mm. High accuracy and resolution. Perfectly suited for applications in CNC machine tools e.g. swivel heads or rotary tables.With various serial interfaces available

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Highly accurate absolute angle measuring system with flat design and integrated bearing. Magnetic operating principle therefore extremely insensitive Perfectly suited for applications in CNC machine tools such as rotary tables. With serial interfaces for Fanuc, Mitsubishi and Yaskawa CNC available.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

The BH25 is a high resolution exposed linear encoder with interferometric measurement signal generation. The BH25 scale has a graduation period of 1µm. The interferometric laser scale principle generates a sinusoidal measurement signal with a signal period of 250nm in the read head. The BH25 is characterized by its small size and high signal quality. It is suitable for resolutions of up to 3.8pm. Due to the reflective scanning and the small design it is perfectly suited for high accuracy X/Y stages with linear motor drive as well as for measurement applications

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High resolution magnetic absolute linear encoder system for CNC machine tools with robust design. The read head is guided contactless without ball bearing Measuring lengths: 70mm - 3.770mm Accuracy: 3+3ML/1.000 µm(p-p) Max. Resolution: 5nm Max. Response speed: 200m/min Extremely robust against vibration and shock Insensitive to contamination such as oil, water, moisture and dust due to the magnetic operating principle Same thermal expansion behavior as steel or cast iron machine bed Compatible with serial protocols from Fanuc, Mitsubishi and Siemens Siemens DriveCliQ version is Functional Safety certified

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAGNESCALE EUROPE GMBH

Germany

High precision magnetic absolute linear encoder for CNC machine tools in robust design Measuring lengths:140mm - 3.640mm Accuracy: 3+3ML/1.000 µm(p-p) or 5+5ML/1.000µm(p-p) Max. Resolution: 10nm Max. Response speed: 200m/min Extremely robust against vibration and shock Insensitive to contamination such as oil, water, moisture and dust due to the magnetic operating principle Same thermal expansion behavior as steel or cast iron machine bed Compatible with serial protocols from Fanuc, Mitsubishi and Siemens Siemens DriveCliQ version is Functional Safety certified

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Highly accurate magnetic absolute linear encoder with slim design for machine tools with Siemens, Fanuc, and Mitsubishi CNCs Easy integration in cramped installation conditions due to the slim design Insensitive to contamination such as oil, water, moisture and dust due to the magnetic operating principle Same thermal expansion behavior as steel or cast iron. Compatible with serial protocols from Fanuc, Mitsubishi and Siemens Siemens DRIVE-CLIQ version is Functional Safety certified

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High-precision absolute angle encoder with flat design with integral bearing Magnetic operating principle therefore extremely insensitive Perfectly suited for applications in CNC machine tools such as rotary tables Serial interfaces for Siemens and Fanuc. Siemens version with Functional Safety certification.

Request for a quote

MINEBEA INTEC GMBH

Germany

The software SPC@Enterprise combines classic filling quantity control with dynamic process control for a wide range of different systems, thereby efficiently supporting quality management of your production processes. Efficient networking of a diverse range of devices and systems from Minebea Intec and other vendors Fast process control due to powerful monitoring program Easily generate production or calibration statistics Displays the current status of checkweighers and metal detectors including daily history, logging of error messages, product changes and events Email dispatch of alarms Simple data backup will return a lower risk of data los

Request for a quote

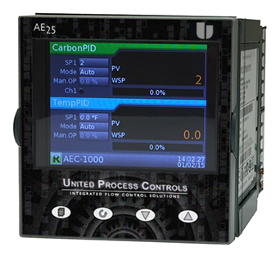

UNITED PROCESS CONTROLS GMBH

Germany

The AE25™ is a ¼ DIN multi-loop process controller provides easy operation and review of process variables and set-point information. FEATURES • controls carbon potential, dewpoint, temperature, and oxygen concentration • paperless chart recorder with USB port for data retrieval • Ethernet (Modbus-TPC) communication port for remote process monitoring and control. • simplified PID tuning with Auto-tune reduces startup configuration time and quickly gets your process up and running fast

Request for a quote

BÜCHI AG

Switzerland

Probes for process control Probes are available to measure the different process parameters. These values can be displayed on our monitoring instrument and recorded in our bls software, see measure & control. Frequently measured parameters are: temperature pressure stirrer speed torque pH IR probes, probes to control particle sizes etc. from other suppliers can be integrated into our pressure reactors or stirred autoclaves.

Request for a quoteResults for

Control process components - Import exportNumber of results

12 ProductsCountries

Company type