- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- contract cutting

Results for

Contract cutting - Import export

TEPROSA GMBH

Germany

Select the material, the quantity and the sheet thickness. If you already have a technical drawing, you can upload it to our server. Wwe only need your contact details to send you an individual offer for laser cutting contract manufacturing! If you need several lamellas, you can simply send off the order form several times.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Tool making & construction: The key to success We know the different industry-specific requirements for stamped parts and parts suppliers. Therefore, our day-to-day work includes very demanding tasks, which we overcome speedily and process reliably. Our spectrum of services for tool construction includes: 3D-CAD/CAM construction and programming (solid works, Peps, HSMworks) Wire-cut EDM (also contract manufacture) with workpiece sizes up to max. 600x400x350 mm Drilling erosion (start hole shooting) with workpiece sizes up to max. 250x350x300 mm Milling technology with workpiece sizes up to max. 650x500x500 mm Turning technology with workpiece sizes up to max. dm 210 x 1000 mm Flat grinding with workpiece sizes up to max. 600x300x375 mm and more…. Even complicated customer requirements are never a problem for us, but are instead a welcome challenge.

Request for a quote

SIMER SAC METAL SHEET PROCESSING & FORKLIFT

Turkey

contract manufacturing with tube profile cnc laser

Request for a quote

SIMER SAC METAL SHEET PROCESSING & FORKLIFT

Turkey

contract manufacturing with cnc laser cutting and cnc bending

Request for a quote

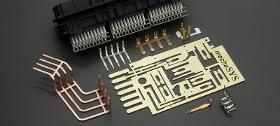

MECHASYS GMBH

Germany

Laser cutting or laser fine cutting of metal, we can precisely process all metallic, non-toxic materials in material thicknesses from 0.2 to 2.0 mm. With our high-precision 1kW fiber laser (Nd: YAG with a wavelength of 1064nm) in combination with highly dynamic linear drives, we can produce your laser cuts in copper and brass. Due to our extremely small focus of 0.05mm, we usually create a cutting cag/ clearance of 0.07mm, so that the most delicate contours (especially inner contours) can be realized without mechanical stress, as the processing takes place without contact. This enables high-quality and precise prototypes and small series in contract manufacturing using cutting lasers. Accuracies of +/- 0.01mm, which are required in the sealing area for plastic overmolding for complete plugs or housings. Dimensions: sheet thicknesses from 0.2 to 2.0mm, max. sheet metal of max. 1,250mm x 1,250mm.

Request for a quote

TEKNO KESIM

Turkey

FOAM CUSTOMIZATION METHODS Depending on the application, quantity and complexity of your equipment, we can use one of several different methods to deliver a customized case interior. Die-Cut Foam Die-cutting foam uses a custom form, or die, to cut the foam to the shape of your equipment. Die-cut foam can be very cost-effective at larger quantities, and we operate a wide range of die presses to give our customers a full range of customization options. ater jet foam cutter uses a high pressure stream of water to cut precise shapes in foam. This foam customization method is ideal for either large or complex foam pieces, which can be cut to precisely match 3D CAD/ CAM models of your equipment. we are located in Turkey istanbul and share us details of your products images and more to calculate price offer sales@teknokesim.com +905350649455 whatsapp

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Contract cutting - Import exportNumber of results

6 ProductsCountries

Company type