- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- continuous motion

Results for

Continuous motion - Import export

MISSAGLIA SPA

Italy

HEFLOMI is a panel made of a special fabric with an antibacterial and antiviral function that purifies the air from harmful substances and allergens and absorbs bad odors emanating from cleaning products and food, eliminating them. By exploiting the continuous motion of the air, it removes polluting molecules in a process of continuous exchange between the air and its surface.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD2 is designed to reface valve seats of the engines of trucks. heavy construction vehicles and small ships. Features The VD2 refaces the valve seat in a lathe-type facing action. The tool head includes two inclined slideways for refacing 30° and 45° valve seats. A single point turning tool is clamped to tool slide guided in the respective slideway. When the VD2 is rotated around the pilot by hand, the turning tool travels in a circle around the valve seat with continuous outward transverse feed motion under the correct seat angle. A steady rest which is mounted on the cylinder head stabilizes the VD2 below the crank handle. The steady rest eliminates runout when rotating the VD2 around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Working Principle: The counterbore is machined to the preset depth by the simultaneous application of both a rotary and vertical or horizontal feed motion to the carbide cutting insert. While the cutting insert rotates in a circle around the counterbore, a feed gear mechanism ensures a continuous feed motion. The lathe-type refacing action provides smooth and closely fitting contact surfaces for oversize valve seat rings. Features: The motor drive unit of the VD4HD-ADM is identical with the motor drive unit of the VD4HD Valve Seat Refacing Machine and, therefore, is only required, if no VD4HD is at hand. Two types of exchangeable boring gear heads are available. The standard AV boring head is provided with a vertical slide for counterboring. The optional AVH boring and facing head is provided with a vertical and a horizontal slide for counterboring and facing the bottom of the bore.

Request for a quote

OPTIMA LIFE SCIENCE GMBH

Germany

- Modularity: Quick change and addition of modules - Scalability: Machine can be extended from an entry level machine to a fully-automated production line - Intermittent motion: Lab machine - Continuous motion: Pilot plant production - Continuous motion, multiple lanes: Large volume production Applications - Product development - Manufacturing of product samples - Clinical tests - Market launch - Production Perfect for new products and business areas - Covers small and medium production needs

ZUMBACH ELECTRONIC AG

Switzerland

The pivoting support DVW 1 is a simple accessory for some ODAC® laser head models used for such applications. With the continuously pivoting motion of the laser heads combined with the electronic "minimal value detection" of the relevant dimension, the height (or thickness) will be measured very accurately in most cases. The device needs no additional electronics. It is, together with the laser measuring head, directly powered and controlled by the respective processor unit. Properties Ability to measure minimum and maximum product dimensions Adjustable oscillation speed for optimal measurement Individual adjustment of oscillation angle by means of DVO 2. Fixed oscillation angle with DVW 1 (+/- 10 degrees) Solutions for single-axis, dual-axis and triple-axis ODAC measuring devices. Benefits Robust & durable design Measurement independent of product orientation Best measuring results by means of adjustable holder for optimal positioning of the unit

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

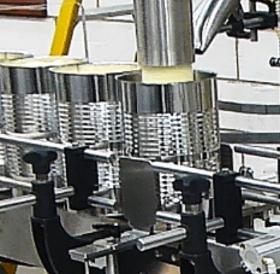

SAPLI SOLUTIONS

Spain

Continuous or Intermittent motion highly Accurate Rotary Powder Filler is a suitable solution for a wide range of powdered and granule products to be filled with medium and high production rates. One or more filling stations options, depending on product flow characteristics and a packaging formats. Rotary machines are available with over turrets of 12 to 48 pockets, with outputs up to 400 containers per minute. These can be integrated with gross or tare and gross check-weigher feed-back systems.

Request for a quoteResults for

Continuous motion - Import exportNumber of results

7 ProductsCountries

Company type