- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- continuous conveyors

Results for

Continuous conveyors - Import export

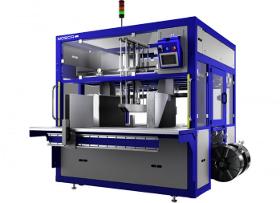

SYNERLINK

France

EL LOAD is an automated packing station for bulk products or packs. The products (cups, bottles and packs) can be: - Grouped, referenced and picked up when stationary - Synchronized / timed and picked-up in continuous movement (following the conveyor) Open boxes or boxes with flaps can be: - Loaded when stopped after referencing - Loaded in continuous movement (following the conveyor) EL LOAD is totally designed to be interfaced with any SYNERLINK machines.

Request for a quote

NOVELTY STEEL

Turkey

Belt conveyors used for handling bulk solids utilize rubber-covered belts, where the inner carcass of the belt provides the necessary strength to pull and support the conveyed load. The carcass is shielded from damage by layers of rubber, which may vary in thickness depending on the specific application. Belt conveyors exhibit the capability to transport materials across a broad range of rates, spanning from just a few kilograms per minute to several thousand metric tons per hour. ndard troughing angles are commonly set at 0°, 20°, 35°, and 45°. The angle of surcharge is a material-specific property and can be compared to the dynamic angle of repose. The power requirements for belt conveyors hinge on various variables, including the conveyor’s profile, the type of drive-pulley arrangement, belt tensions, belt speed, and idler spacing.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Continuous sealers type SCV and SCH, to seal bags made of PE, PP, soft PVC, polyamide paper, aluminium or cardboard tabs as they pass through the sealer. - Adjustable speed from 0 to 12 m/minute - Temperature adjustable from 0°C to 400°C. - Width of the weld: 10 mm - Maximum weight on conveyor belt: 10 kg - Optional: bag counter - hot stamping on the weld seam

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Extreme-temperature grease on the basis of perfluorinated polyether oils (PFPE) for use in food processing technology at maximum loads and temperatures. Grease lubrication of friction and rolling bearings in the high-temperature range Application, for example at tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals/fuel Advantages and benefits Maximum water and steam resistance Extraordinary resistance to chemicals, for example to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, such as sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Excellent plastic and elastomer compatibility For long-term lubrication of lubrication points subjected to high pressure up to 300°C

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of friction and rolling bearings in the high-temperature range up to 300°C Lubrication of tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals Lubrication of bearings under influence of fuel Advantages and benefits Absolutely resistant to water and steam Resistant to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, for example sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Broad range of applications above the temperature limits of other lubricating greases Excellent wear protection Reduced maintenance and lubricant costs due to possible lifetime lubrication Excellent plastic and elastomer compatibility

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Load-out systems with shuttle conveyor maximizes scrap removal. The PRAB shuttle conveyor load-out systems automate final load-out of stamping scrap, die scrap and machining scrap into large trailers or railcars to maximum container fill. Open frame construction provides personnel quick and safe access to carry over. This scrap material conveyor features a traversing, bidirectional steel belt designed for final load-out of stamping and die scrap, as well as chip processing, into large trailers or railcars. The infeed conveyor and continuous back and forth operation provide even distribution into larger scrap containers where swivel chute systems would be inadequate

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Eliminate misting and plant air quality issues. Ideal for air cooling of hot die castings. Eliminates misting and air quality issues associated with water quench conveyors. Run continuously or indexing. The application of a casting cooler can help meet operational needs while eliminating misting and improving plant air quality. Extended lengths are available with single and/or multiple fan designs for this specific kind of scrap metal equipment. Coolers can run continuously or indexing.

Request for a quote

REP INTERNATIONAL

France

Rotocure Conveyor, compression machine from our partner Tung Yu. Rotocure is a continuous curing conveyor used to produce rubber sheets of specific dimensions and shapes.

Request for a quote

LANTECH

Netherlands

Profit Pack Machine Bypass Mode This option allows the Profit Pack product conveyor to continue to run, while bypassing the Sealer. Access through HMI. Profit Pack Complete Detection Beacons This option provides a complete detection four color LED beacon on the Erector that alerts operator. Top to bottom; Red burning - general failure, Orange blinking - low tape, Orange burning - out of tape or broken tape, Blue blinking - low blanks in magazine, Blue burning - magazine empty, Green burning - machine in standby. Detection on the Sealer; Orange blinking - low tape, Orange burning - out of tape or broken tape, Green burning - machine running or standby. Profit Pack Product Conveyor Height Adjustment Hydraulic height adjustment on Profit Pack product infeed conveyor between 39.36" - 47.25" (1000-1200mm). Infeed Product Conveyor Width 7.87" (200mm) Smooth Surface Belt Standard smooth surface belt with width of 7.87" (200mm). Infeed Product Conveyor Width 13.77" (350mm) Smooth Surface...

Request for a quote

LANTECH

Netherlands

Profit Pack Machine Bypass Mode This option allows the Profit Pack product conveyor to continue to run, while bypassing the Sealer. Access through HMI. Profit Pack Complete Detection Beacons This option provides a complete detection four color LED beacon on the Erector that alerts operator. Top to bottom; Red burning - general failure, Orange blinking - low tape, Orange burning - out of tape or broken tape, Blue blinking - low blanks in magazine, Blue burning - magazine empty, Green burning - machine in standby. Detection on the Sealer; Orange blinking - low tape, Orange burning - out of tape or broken tape, Green burning - machine running or standby. Profit Pack Product Conveyor Height Adjustment Hydraulic height adjustment on Profit Pack product infeed conveyor between 39.36" - 47.25" (1000-1200mm). Infeed Product Conveyor Width 7.87" (200mm) Smooth Surface Belt Standard smooth surface belt with width of 7.87" (200mm). Infeed Product Conveyor Width 13.77" (350mm) Smooth Surface...

Request for a quote

POLIFILM

Belarus

provides a connection point with a rough and fleecy surface, preventing displacement of the glued ones; has high flexibility and elasticity for fixing rough surfaces; is easy to use, environmentally friendly and easy to dispose of; connects elements together, keeping their fragile parts intact. for gluing materials that are subject to heavy loads; for laying floor coverings; for temporary restoration work; for decoration of exhibition premises; for installation of materials that must remain motionless even under mechanical influence; for gluing various rolled materials during their production, including on continuous conveyors. Quantity pcs. 64

Request for a quote

EUROLINIA

Belarus

EUROLINIA infrared industrial tunnel ovens are designed to rapidly and uniformly heat the surface of cables, wires, polymer pipes and tubes, dry fiber optics and etc. in batch or continuous conveyor production using targeted high-intensity infrared radiation. High efficiency is achieved by concentrating high-intensity infrared radiation and by using a circular reflector that efficiently distributes radiant energy inside the heating chamber. Additional efficiency is gained by installing three-level thermal protection. EUROLINIA tunnels have modular structure: one heating section is 2 meters long, you can connect up to 8 sections in one production line. Maxumum temperarature in the tunnel can reach up to 700C. Tunnels can have multiple separate heating zones and can be equiped with a conveyor. To ensure high-quality, high-precision surface heating, industrial tunnel ovens are also equipped with an automatic heating control system (APCS).

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Side Sealer Shrink Wrap Machine is a fully automatic unmanned operation of an economic side sealing packaging machine, that is widely used in the assembly line of mass production and packaging. It uses an electronic eye to detect products as they pass through on the conveyor. After products pass, a single-sealing arm running perpendicular to the film closes behind the product. As the product continues to pass to the conveyor, a side sealing wheel makes the final seal enclose the product. The advantage of the side seal machine comes from the ability to wrap longer products. The width of the product is limited to the verticle sealing bar, but the length can be as long as needed. A perfect option for shrink wrapping molding, pipes, wood, and other elongated items. The horizontal knife in the sealing part adopts a vertical drive, and the vertical knife adopts a constant temperature side sealer. The sealing line is straight and firm to achieve a beautiful sealing effect.

MOSCA GMBH

Germany

Ultrasonic sealing system with electronic self-calibration High-end Standard 6 sealing unit Dispenser variably mountable Intuitive user guidance via colored touch panel Electromechanically driven aluminum rollers ensure an optimal product transport Continuously adjustable conveyor speed from 0.2to 1.0m/s Bundle positioning via increments by metrical input of the strapping positions Open design without protective coverings - CE marking inclusive conformity declaration Infeed side guidance Extremely low energy consumption

Request for a quote

MOSCA GMBH

Germany

• SoniXs Utrasonic sealing unit in standard-6 version • High availability due to controlled frame • 5-sided electromechanical package alignment • Continuously adjustable conveyor speed • Laterally driven transport belts • Driven top belts • Electro-mechanical package stop and hold-down device • Intuitive user guidance via colored touch panel with ergonomic positioning options • ATR – Automatic cycle rate regulation • Easy maintenance due to automatic removable strapping unit • Automatic machine adaptation to package dimensions via adjustable recipes • CE marking inclusive conformity declaration

Request for a quote

MOSCA GMBH

Germany

• SoniXs Utrasonic sealing unit in standard-6 version • Easy accessibility and tool-free dismantling of strap path components • Stepless turnable operation panel (0° - 180°) for many-sided operation • Adjustable strap tension via potentiometer • Programmable strap tension value • Strap coil changeable from the front and the side • Automatic strap coil change and threading system • Strap end detection with ejection of remaining strap • Automatic strap loop ejection • Extremely low energy consumption • Stand-by mode • 4 castors, 2 of them lockable • CE marking inclusive conformity declaration • Soft strapping selectable for sensitive packages • Easy operation over digital display in the control panel • Potential-free contacts to upstream and downstream machines • Continuously adjustable conveyor speed from 0.1 to 1.0 m/s • Parameter control panel for setting strapping parameters • Selector switch for single, double or multiple strapping

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Roller transports, if required with workpiece transposition from one to two lanes, accumulation and disc roller conveyors or bar transport units complement our portfolio of continuous conveyor systems. VEN TRANS system techniques enable tailor-made workpiece conveying and handling concepts. We create Our solutions take into account

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

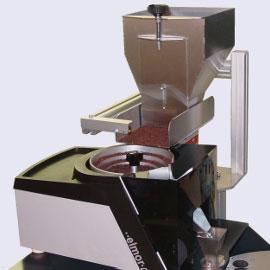

ELMOR

Switzerland

The feeding conveyor elmor 610 serves to refill the counting machines elmor C1, C3 or CX continuously and unattended. The feeding conveyor elmor 610 consists of a hopper, a feeding unit and a level sensor. Once the filling level in the conveyor bowl of the counting machine elmor C1, C3 or CX falls below a minimum value, it is automatically refilled through the feeding conveyor elmor 610. For small and light parts such as seeds, a linear vibratory conveying device is used. The hopper has 4 liters of storage volume. For large or heavy items refilling is done via a belt conveyor. The storage volume in this case is 10 liters or more. With the feeding conveyor elmor 610 a long operating autonomy is achieved, especially when the couning machine runs in combination with a filling or packaging machine. Technical data Suited for parts larger than 2 mm in diameter Type of conveyor: linear vibratory conveyor or belt conveyor Storage volume: 4 litres (vibratory conveyor) or 10 litres (belt conveyor) Level sensor: a precise sensor switches the conveyor on and off depending on the level to be regulated elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Continuous lubrication systems. Movements, roller chains, rollers of the roller bearings, cams operating in ovens or stoves. Glass manufacturing machines. Conveyor chains for continuous hot-pressing machines.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Continous lubrication system. Movements, roller chains, rollers of the roller bearings, cams operating in ovens or stoves. Chains and bars in continuous wood panel production lines. Glass manufacturing machines. Conveyor chains for continuous hot-pressing machines.

Request for a quote

FÖRDERTEC GMBH

Germany

The trough chain conveyor is an important piece of transport equipment for bulk goods in the field of continuous conveyors. Our trough chain conveyor can be operated up to an installation angle of 90°. The discharging and dosing is carried out in completely closed system and can also be designed to be dust-tight and pressure-tight. Each system is planned and designed individually and is tailored to the customer requirements.

Request for a quote

CORFIN LUBRICATION

Turkey

Calcium sulfonate greases are commonly used in automotive, agriculture, construction, mining, paper production, iron and steel mills and the food industry. Specific automotive applications include chassis, ball joints, universal joints and wheel bearings. Industrial applications include continuous casters, conveyors, ball mills, crushers, offshore and underwater applications. Calcium sulfonate greases are also used in motorized steam valves to control high pressure steam. These steam valves are typically found in nuclear power plants and thermal manufacturing stations. It is also known that the calcite particles found in calcium sulfonate greases make them a good choice for high temperature applications. Calcium sulfonate greases are generally beneficial in rust-inhibiting performance and oxidation stability is considered good or excellent. Rust inhibitors are surfactants that neutralize acids on the metal surface.

Request for a quoteResults for

Continuous conveyors - Import exportNumber of results

23 ProductsCountries

Company type