- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cold-rolled products

Results for

Cold-rolled products - Import export

BS STEELWORKS GMBH

Germany

Cold rolled steel is low carbon steel produced by a "cold rolling" process and processed at near normal room temperatures. Cold rolled steel offers superior strength and machinability. Cold rolled steel sheets are often used for engineering products where close tolerances, concentricity, surface smoothness and coated surfaces are required.

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

EVROMARKET

Russia

This product can be made of any laminated chipboard, solid wood or cold rolled steel. This product can be finished with any type of wood \ particleboard or engineered stone, branded with every brand and equipped with lighting.

Request for a quote

EVROMARKET

Russia

This product can be made of any laminated chipboard, solid wood or cold rolled steel. This product can be finished with any type of wood \ particleboard or engineered stone, branded with every brand and equipped with lighting.

Request for a quote

EVROMARKET

Russia

This product can be made of any laminated chipboard, solid wood or cold rolled steel This product can be finished with any type of wood \ particleboard or engineered stone, branded with every brand and equipped with lighting

Request for a quote

EVROMARKET

Russia

Metal parts of this product can be coated in various colors on demand Rails material: 0.8mm cold rolled steel Shelves and back panels material: 0.8 mm cold rolled steel Uprights and brackets material: 2.5 mm cold rolled steel This product can be equipped with risers and dividers, shelf lights, ticket inserts and inclined shelves with two-position brackets This product can be fabricated in any other sizes on demand This product can be painted or stained in various colors on demand.

Request for a quote

EVROMARKET

Russia

Rails material: 0.8mm cold rolled steel Shelves and back panels material: 0.8 mm cold rolled steel Uprights and brackets material: 2.5 mm cold rolled steel This product can be coated in various colors on demand This product can be equipped with risers and dividers, shelf lights, ticket inserts and inclined shelves with two-position brackets This product can be fabricated in any other sizes on demand

Request for a quote

EVROMARKET

Russia

Rails material: 0.8mm cold rolled steel Shelves and back panels material: 0.8 mm cold rolled steel Uprights and brackets material: 2.5 mm cold rolled steel The product can be equipped with ticket inserts. lighting, wooden shelves, pallets and baskets This product can be coated in various colors on demand This product can be fabricated in any other sizes on demand The price is given for the product of minimal height and width, with N shelves of nn-nn-nn cm depth and a base shelf of nn cm depth

Request for a quote

EVROMARKET

Russia

Rails material: 0.8mm cold rolled steel Shelves material: 0.8 mm cold rolled steel Uprights and brackets material: 2.5 mm cold rolled steel This product can be coated in various colors on demand This product can be equipped with risers and dividers, shelf lights, ticket inserts and inclined shelves with two-position brackets This product can be fabricated in any other sizes on demand The price is given for the product of minimal height and width, with 3 shelves of 30-30-30 cm depth and a base shelf of 40 cm depth

Request for a quote

SCHOCK GROUP

Germany

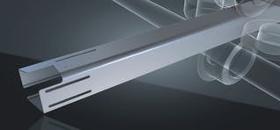

SCHOCK is the specialist in the production of cold-rolled profiles according to individual customer requirements. With a wide range of different technologies, we manufacture special profiles as customized functional elements up to complete assemblies.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK is your specialist in the production of cold-rolled profiles tailored to individual customer requirements. With a wide range of different technologies, we manufacture special profiles as customized functional elements up to complete assemblies. SCHOCK's roll forming technology operates economically and material-efficiently, offering significant advantages in product design: Unlimited range of shapes Highly precise functional dimensions Economical material utilization Energy-efficient manufacturing process SCHOCK special profiles are characterized by the highest precision and top-notch workmanship. With SCHOCK's roll forming technology, we produce profiles with extremely tight tolerances and excellent product properties. Thanks to creative tool solutions, we manufacture virtually burr-free profiles and process different materials with a tensile strength of up to 1000 MPa.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INOTEK MAKINA

Turkey

SCC type cement conveyors are designed for conveying material from silos in cement batching plant. They are supplied in standard sizes from Q114 to Q323 mm with direct drive unit standard reducer ratio available 140,200,240 rpm. Electric motor: IE2 efficiency class Reducer: Standard İNOTEK production Flight: Cold rolled Screw flight ( 4 mm thickness) Intermediate Hanger Bearing: High wear resistance End Bearing: Long-life Inlet and Outlet: Conical, square, rectangular as per customer demand. Inspection and Maintenance Cover: Easyly disasembled for hanger bearing greasing and regular inspection .

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: 1.4301 (X5CrNi18-10) Type of production: cold-rolled, 2G Surface finish: ground Grain: 240 Ground sides: both sides Standard: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 1.5 - 5 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500 Foliation: Foil 4228, laser protection foil

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: 1.4301 (X5CrNi18-10) Type of production: cold-rolled, 2J Surface finish: brushed Ground sides: one-sided Standard: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 0.8 - 6 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500 Foliation: Foil 4228, standard foil, laser protective foil

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: sheet Material: EN AW-5754 (AlMg3), 3.3535, H22 Type of production: cold-rolled Condition: work-hardened, annealed, 1/4 hard Surface finish: Mill-finish Standard: EN 573/EN 485 eClass 9.1: 35020501 UNSPSC 11.2: 30102506 Dimensions: Thickness (mm): 0.5 - 6 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000 Foliation: no foil, protection foil, no paper

Request for a quote

YCSMAKINE

Turkey

YCS MACHINE (YUCESAN) is manufacturing shutter door profile Cold roll forming machines using high technology in its facility in Turkey since 2004. We bring together the Turkish engineering discipline with our knowledge and experience of more than 18 years in the metal door profile forming machines and other related components, development, and production. We design and produce our profile-forming machines based on their efficiency, reliability, life-long-running tooling, and craftsmanship. We are exporting 80% of our machines abroad and our profile forming machines running in more than 30 countries. More about us; More than 18 years of Experience in Metal Shutter profile cold roll forming machines production. Precise tooling and production using Japanese and German, Korean CNC machines. nous sommes fabricant de Profilage, Profileuse pour volet roulant Profileuse, de profilage, Ligne de poinçonnage profilage

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

This material group comprises C-steel with low carbon content, good formability and fineblanking quality. Due to case hardening, the components have low-wear surface layers with high hardness and sufficient toughness in the core. They thus combine numerous properties and application possibilities in a wide variety of industries. To increase the wear resistance, you can also carburize or carbonitrate partial areas. C 10 E, C 15 E /➔ according to DIN EN 10132 - 2 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

State-of-the-art technology and extensive knowledge in the processing of steel characterise our location in Bad Salzungen, Germany. For us, performance means a wide range of cold-rolled steels of the highest quality at competitive prices, flexibility and a high degree of readiness to deliver while adhering precisely to the specified chemical and mechanical values. Surface finishing by electrolytic galvanizing and/or subsequent customisation of your goods are possible for us. We offer all our customers spooled materials with volumes of over 200,000 metres of metal strip per spool. This further development means a considerable advantage for our customers. Personnel-intensive set-up times and machine downtimes are avoided.

Request for a quote

ILK IHRACAT AS.

Turkey

Hot rolled and acid cleaned sheet is enriched by special processes. It reaches the desired thickness by reversible or tandem rolling. At this stage, the sheet is hardened, but becomes formable by continuous annealing or batch annealing. Tempering is applied to improve its mechanical properties. Quality control is ensured through tests and the tempered sheet is shipped in accordance with customer requirements. Cold Rolled Steel Sheet, which is obtained by re-rolling hot rolled and pickled products, has precise dimensions and high surface quality. Product Specifications: DC01, DC03, DC04, DC05, DC06 DC01EK, DC04EK, DC01ED, DC04ED HC260LA, HC320LA, HC380LA, HC420LA Application Areas: Automotive, White Goods, Machinery Manufacturing, Building Industry, Industrial Warehouse Solutions, Panel/Radiator, Fasteners. As Steeling.net, we bring together quality and diversity in cold rolled sheet and offer the highest level of value to our customers.

Request for a quote

MFO S.A.

Poland

Steel profiles and Mounting Rails applicable in central heating systems, ventilation system, fire protection systems and other light constructions. Hot rolled black steel complying with norm PN-EN 10025, PN-EN 10111(hot dip galvanization of ready elements according to norm PN-EN ISO 1461:2011) Cold rolled steel complying with norm PN-EN 10130 Galvanized steel for cold processing and construction galvanized steel complying with norm PN-EN 10346 steel resistant to corrosion complying with norm PN-EN 10088

Request for a quote

BRT GRUP ANADOLU METALURJI

Turkey

Rollers with maximum hardness depth and homogeneity through ultimately clean, classical or gradual hardening methods, and with high precision and advanced technology.

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quoteResults for

Cold-rolled products - Import exportNumber of results

30 ProductsCountries

Category

- Cold rolled steel strips (10)

- Copper sheets and bands (7)

- Display units for shops (4)

- Furniture and shelving, office (2)

- Rolling mills - machinery and installations (2)

- Steel, special (2)

- Aluminium sheets and bands (1)

- Cement-making - machinery and equipment (1)

- Cold rolled sections (1)

- Cutting - steels and metals (1)

- Foundries - copper, bronze and brass (1)

- Rails and sliding frames (1)

- Rolling machines (1)

- Shelving for shops (1)

- Shop fittings (1)

- Steel, carbon (1)