- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coil lines

Results for

Coil lines - Import export

TECHNIC MACHINES

Turkey

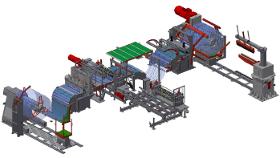

Our coil slitter machine has working thickness range from the coil is beginning from 0.2 mm and up to 20 mm and working width up to 2.100 mm As to requests or slitting work specifications of our customers we offer perfect combinations to our customers for their metal slitter machine researches. We offer different coil slitting line range options, for example heavy duty coil slitting machine, medium duty coil slitter machine or light duty metal slitter machine. We offer alternatives for matching exact metal slitting line machine parameters according to our customer’s demand. Also according to requested working raw material we offer different solutions for our customers for their metal slitting machine research. - Light Duty Metal Slitter Machine - Medium Duty Slitting Line Machine - Heavy Duty Coil Slitting Machine Line

Request for a quote

TECHNIC MACHINES

Turkey

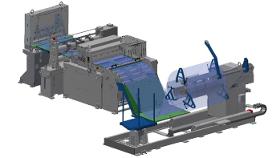

We provide for more economical solution our this Cut to Length Machine model We can consider that It is more feasible for small metal workshops, it requires smaller space and provide low production capacity is we compare with our other Coil Cut to Length Line models We provide with our this model Cut to Length Line Machine, compact system with single chassis straightener and feeder unit and also this model Metal Cut to Length Machine model is with no pit system. We have always optimum solution on our machine models for our customer's researches. Just contact with us for your Coil Cut to Length Line research.

Request for a quote

TECHNIC MACHINES

Turkey

This model cut to length machine line is more feasible for heavy duty work Also it has fast production speed if we compare with our compact model If you are searching coil cut to length machine with high speed and heavy work, our this model is best solution It is the professional, fast and feasible for heavy coil cut to length line work Cut to Length Line with pit system is preferred by professional steel working companies and trading companies Just contact with us for your Cut to Length Machine research, we will find the optimum solution for your need

Request for a quote

TECHNIC MACHINES

Turkey

Our cut to length machine has working thickness range from the coil is beginning from 0.2 mm and up to 20 mm and working width up to 2.100 mm As to requests or metal cut to length work specifications of our customers, we offer perfect combinations to our customers for their metal cut to length machine researches. We offer different coil cut to length line range options, for example heavy duty cut to length machine, medium duty metal cut to length machine or light duty metal cut to length line. We offer alternatives for matching exact cut to length line machine parameters according to our customer’s demand. Also according to requested working raw material we offer different solutions for our customers for their sheet metal CTL line machine research. - Light Duty Cut to Length Machine - Medium Duty Cut to Length Line Machine - Heavy Duty Coil Cut to Length Machine

Request for a quote

BOSPORAS

Turkey

Brand new Coil Slitting Line is on sale! 0.5 - 3 mm Thickness x 600 mm Width x 6 Ton Coil Weight The line is not used, in April 2024 production. Ideal line for production of Galvanized Grounding Strip production. Please contact for further details. #coil #slitting #coilslitting #slittingline #uncoiler #decoiler #slit #recoiler #tensioner #coilprocessing #earthing #grounding #grounding #GalvanizedGroundingStrip #GroundingStrip #Strip

Request for a quote

BOSPORAS

Turkey

BOSPORAS ADM Series Coil Slitting Line, allows sheet metal materials to slit easily, heavy tonnage work to be done and user operator to work faster, easier and productive thanks to our technical team developing it with high-end technologies.

Request for a quote

GSW SCHWABE AG

Germany

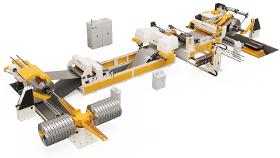

If you need two Coil Reels to hold one coil, you need a Heavy-Duty Coil Feed Line above all. One that is designed extremely robust and knows to subdue even materials of highest bounce and largest cross-sections.To ensure this, we have taken no heed to cost savings but went by the maximum principle: 2 Coil Reels with high-performance arbors retain the coils from left and right. 2 x 2 hydraulic arms secure them from top and bottom – each with eight tons pressure force, each with hydraulically driven snubber roll. The loading is done with one central lifting gear built into a super-duty running frame for the V-nest. Hydraulic manipulators with pivoting and bending function support the threading of the material. On the receiving end, a Pre-Straightener with 200mm work rolls takes over, after hydraulic edge guides have ensured central entry. Now, if someone asks us our definition of “heavy-duty”: We find 36.000 kilogram coil weight and 2.

Request for a quote

GSW SCHWABE AG

Germany

Slit metal often has camber. GSW builds Camber Straighteners, that help remove this defect. Coil Feed Lines that process small crosssections often only need minor straightening efforts. Here, we can help with pullthrough Straighteners also known as Flatteners. We usually mount them at the entrance of our Servo Roll Feeds or Air Feeds. Wire materials also often have a coil set – sometimes in two levels even. Single and dual Wire Straighteners help making such bent wires straight again.

Request for a quote

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

An innovation for decorative applications is the stripe coating on our narrow Coil Coating line at First American. This is a complete coil coating process in which we are able to leave tightly toleranced, unpainted stripes on the carrier strip. These give the decorative effect to the finished article, while the coated areas are coated with an adhesive system (e.g. automotive trim material or white coating with a defined black stripe, etc.). As always, all metal strips available on the market can be used as metal carriers; all coatings can also be used. This leads to a smart product, allowing you a multitude of new, innovative applications.

Request for a quote

GSW SCHWABE AG

Germany

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

SACFORM/AGMLINE

Turkey

Our Coil Slitting Lines are Turnkey Systems Design According to Special Demands and Needs of our Customers. With Our Continuously Renewing and Developing Design Studies of our R&D Team, By Increasing the Slitting Speed of Slitting Lines, High Capacity Works Can Be Done and It Enables the Operator to Work More Quickly and Efficiently. By Means of Custom-made Designs by R&D Team, SACFORM offers the Slitting Lines Produced in International Quality with Much More Affordable Costs.

Request for a quote

SACFORM/AGMLINE

Turkey

SACFORM Cut to Length Line consists of Decoiler, Servo Feeder with Straightener, Shear System and Stacking Units. With all these equipment, our Line is a feature-complete Turnkey Project for our Customers.

Request for a quote

GABELLA MACCHINE SPA

Italy

Cut-to-length lines for T-shaped panels Slitting and recoiling lines with automatic separators positioning Dedicated plants for pre-painted,? film-coated or other special materials (stucco-design, mesh, ground surfaces…) Special lines for panels production, with punching, shearing, roll-forming and bending Continuous punching lines Spool recoiling lines De-burring lines Combined lines with partial cut, where a part of the strip is recoiled for future use Machines for mass production or very flexible plants for small productions Cut-to-length and recoiling lines, with coils packaging stations. Customized and very enhanced productions, which integrate the sheet-metal processing with rotating turret punching (possibility of up to 24 different tools? a time, even in “multitools” solutions) or fiber laser cut.

Request for a quote

TECHNIC MACHINES

Turkey

If you are looking fast cut to length machine which can correct also damaged metal coils, our this combination is fit for your request. It is the most professional solution for cut to length machine line solution. Because it can correct also damaged coils, it is preferred by professional steel working companies and steel dealers. Also with the help of rotary shear, our this coil cut to length line model can reach pretty high speed. If you are looking for professional cut to length machine solution, just contact with us. We will provide for you optimum solution on your cut to length machine research.

Request for a quote

BOSPORAS

Turkey

BOSPORAS ADM-1600 coil slitting line, allows sheet metal materials to slit easily, heavy tonnage work to be done and user operator to work faster, easier and productive thanks to our technical team developing it with high-end technologies. BOSPORAS is always among the first ranks in its field with its technical team and many years of experience in coil slitting process while sharing all knowledge and high technologies with the iron-steel industry. Sturdy, effective and long-lasting slitting lines are manufactured with high costs but BOSPORAS investments, experiences and state-of-the-ark technologies offer the world-quality slitting lines for the lowest cost possible while prioritizing the customer satisfaction.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfill the need of cutting the sheet metals between 600 and 1600 mm of width and, 6000 and 30000 kilograms of weight

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfill the need of cutting the sheet metals between 600 and 1600 mm of width and, 6000 and 30000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfill the need of cutting the sheet metals between 600 and 1600 mm of width and, 6000 and 30000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 millimetres of width, 6.000 and 30.000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 millimetres of width, 6.000 and 30.000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfill the need of cutting the sheet metals between 600 and 1600 mm of width and, 6000 and 30000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 mm of width, 6000 and 30000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 millimetres of width, 6.000 and 30.000 kilograms of weight.

Request for a quote

BOSPORAS

Turkey

Our coil cut to length line machines have capacity to fulfil the need of cutting the sheet metals between 600 and 1600 millimetres of width, 6.000 and 30.000 kilograms of weight.

Request for a quote

ANDRITZ KAISER GMBH

Germany

The lines are equipped for such processes as trimming, recoiling, precision leveling, and cutting-to-length. ANDRITZ Sundwig manufactures cut-to-length lines for steel, stainless steel, aluminum, and all types of non-ferrous metals in strip widths from 600 to 3,200 mm and strip thicknesses from 0.1 to 25.0 mm. Our references include steel plants, steel service centers, the automotive industry, and metal processors of various kinds. Individual customer solutions distinguish our innovatively designed, frequently proven, and highly productive lines ANDRITZ METALS cut-to-length lines cut aluminum sheet and strip for industrial applications and for the aeronautical industry to the desired precise dimensions. These lines can process coils and sheets of up to 2,850 mm in width, up to 15 m in length, and at strip thicknesses between 2 and 15 mm.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

* Closed Loop Siemens CNC Servo Control System * Multi kW high speed & efficient Fiber and Disk laser * High Accuracy Cutting * Cut to line feature without shearing * Custom Size Cutting Bed * Rolling Cutting Table * Class I Enclosure Sheet Edge Detection Sensor IEC60825 & FDA & CE approval Coil Fed Laser Cutting Line Equipments * Loading Car capacity up to 30 tons * Coil Outer Diameter up to 2200 mm * Remote Control * Adjustable Drum Rotary Speed * Operation Controlled by Laser Sensor We have manufactured and sold 200+ laser cutting systems worldwide We have produced laser cutting systems which are generated by Fiber ,CO2 and Disk Lasers We have installed systems for global brands We provide project-based automation solutions

Request for a quote

LASER ISSE LASER TECHNOLOGIES

Turkey

ONE Line TWO Methods Coil Fed Shear Blanking & Laser Cutting Line The Blanking Line cuts all your custom blanks direct from the coil with our turnkey solutions, utilising automation for feeding levelling cutting and stacking of all cut parts. Shear Cutting provides rapid cutting of blanks at any size Laser Cutting offers high speed cutting straight lines, trapezoid and any shape blanks for your production requirements

Request for a quoteResults for

Coil lines - Import exportNumber of results

31 ProductsCountries

Company type

Category

- Cutting - machine tools (12)

- Metallurgy - machinery and installations (4)

- Metal straightening machines (3)

- Laser - cutting and welding machines (2)

- Mechanical surface treatment - machinery (2)

- Boilers, domestic (1)

- Cutters (1)

- Industrial cutting machine tools (1)

- Machine tools, metal shaping - parts and accessories (1)

- Metals - Machines & Equipment (1)

- Shearing - steels and metals (1)

- Steels and metals - surface treatment and coating (1)

- Water-heaters, domestic (1)