- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coil handling

Results for

Coil handling - Import export

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

GSW SCHWABE AG

Germany

If you need two Coil Reels to hold one coil, you need a Heavy-Duty Coil Feed Line above all. One that is designed extremely robust and knows to subdue even materials of highest bounce and largest cross-sections.To ensure this, we have taken no heed to cost savings but went by the maximum principle: 2 Coil Reels with high-performance arbors retain the coils from left and right. 2 x 2 hydraulic arms secure them from top and bottom – each with eight tons pressure force, each with hydraulically driven snubber roll. The loading is done with one central lifting gear built into a super-duty running frame for the V-nest. Hydraulic manipulators with pivoting and bending function support the threading of the material. On the receiving end, a Pre-Straightener with 200mm work rolls takes over, after hydraulic edge guides have ensured central entry. Now, if someone asks us our definition of “heavy-duty”: We find 36.000 kilogram coil weight and 2.

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

SCHNELL SPA

Italy

Coil Spider is a safe and small lifting device that, due to its uptodate features, can hook from the outside rolled and drawn coils (either rewinded or not). Coil Spider is equipped with an automatic release and hiding guns (patented) which combined with its reduced dimensions allow it to unload goods from trucks and payoffs quickly and safely also in case of very low cranes.

Request for a quote

KEDY

Turkey

Introducing the KEDY K4500 Coil Lifting Tongs, the ultimate solution for handling heavy coils with ease. Engineered to provide maximum strength and stability, our tongs are made of durable materials that can withstand heavy use, ensuring long-lasting performance and reliability. The unique jaw design securely grips the coil, preventing slippage and ensuring a secure hold. The tongs also have adjustable jaws to accommodate coils of different sizes, making it a versatile tool for various industrial applications. In addition, the ergonomic handle design provides a comfortable grip, reducing fatigue and increasing safety during extended use. Don't let heavy coils slow down your production process. Trust the KEDY K4500 Coil Lifting Tongs to handle the heavy lifting for you. Order yours today and experience the difference it makes in your operations.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

GSW SCHWABE AG

Germany

Safety for the workers, no damage to the coils Our practical hoists are easy to operate – for years at a time. On top of that suitable optional equipment is available.

Request for a quote

GSW SCHWABE AG

Germany

Thrust Chain Systems and Die Trucks für safe and quick handling of dies with up to 21t weight.

Request for a quote

GSW SCHWABE AG

Germany

Turn your forklift truck into a crane by simply attaching the load hook onto the fork arm. Coils can safely be pivoted in connection with a Coil Tilting Hook, series T. Coated version (RAL 2000, orangeyellow) or hotdip galvanised.

Request for a quote

GSW SCHWABE AG

Germany

crane forks easy to adjust to match all sizes of pallets all crane forks meet the requirements of the accident prevention regulation of the trade association quadruple safety against breaking The tines for carrying the load during the loading process tilt upwards if forks with autobalance are used. An unintentional slipout of the load can therefore be ruled out.

Request for a quote

GSW SCHWABE AG

Germany

individual or double post materialsaving hardwoodlayer security swords for thin materials easy to push and to swivel post placable without basement or bracing to the ground easy to shift with crane or stacker

Request for a quote

GSW SCHWABE AG

Germany

material sparing uptake and deposit of coils coil uptake in standing and lying position handover to vertical or horizontal coil reel It is possible to singularize coil stacks as well as to temporarily store them at the production machine in upright or horizontal position. suitable for material widths of up to 500 mm the automatic positioning of the tilt nose guarantees a straightford uptake of the coil. The edge of the material is also treated with more care. The largescale, rounded coil support in the tilt nose prevents the material at the coil eye to be damaged. secure handling with inbuild guide handle, tilt nose automatically slides below the coil coil can be lifted jerkfree because of its unrolling coil nib it is not possible for the coil to slip off during transportation

Request for a quote

GSW SCHWABE AG

Germany

Coil Cradles are made to help unwind coils in rough production environments. Mostly combined with a straightening unit, they work with narrow and thick materials. Built to last, Coil Cradles offer quite a few advantages Simple handling of even hightensile materials with strong clockspring, short setup times, an elaborate coil handling concept which gives a chance to rewind of unfinished coils. By using serial straightening units, type RMA and RMZ, everything is well fitting. To achieve short mounting times and easy accessibility, the complete machine body features a one piece tiebar design machined with most modern CNC equipment. Coil Cradles, CradleStraighteners and CradleFeederStraighteners thus are very efficient too. Consequently, their compactness, efficiency, safety and operator friendliness melt into a coil handling solution which underlines GSW’s lead in technology. Performance data Up to 8 t coil weight, 700 mm stock width and up to 13mm thickness

Request for a quote

GSW SCHWABE AG

Germany

Upenders are designed to safely tilt big and heavy coils – either from horizontal into vertical or reversed. This fast and easy coil handling solution gets rid of “adventurous” tilting methods that often will endanger the operator. Chains and other lifting aids which damage the coil rims become obsolete. Upenders allow 90 degrees tilting of coils; Combination machines will also rotate 180 degrees. Both can handle up to 25 tons.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The versatility and and capability of LAWECO products is most notably shown in coil processing systems. In the infeed and outfeed areas, coil lifting carriages primarily handle the coil. In conjunction with various rack systems even complete solutions can be realised. In the stack areas, stationary and movable scissor lift platforms provide the required handling. Here, it is also our goal to respond to the wishes and requirements of our customers and to provide individual solutions. Load bearing capacity up to 150 t Hydraulics with switching or proportional valve technology Movable or stationary With coupling facility With installed materials handling technolog With or without synchronous run control

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

Low-cost bellows version for zero-pressure handling of solid or liquid media for which Allflex is too expensive. Compressible to approx. 40% of overall length. Good axial and lateral movement. For information on temperature and media resistances please see our Simon resistances chart. Construction: Tube in special quality depending on the medium to be handled Coiled profile Fabric inlays Optional: Concealed steel spiral UV, ozone and weather-resistant cover Interior and exterior corrugated Couplings at both ends In fixed lengths with cuffed ends and/or widened hose endings. Other versions and dimensions on request.

Request for a quote

EC PLAZA

South Korea

TRIS supplies tubes of various specifications and steel grades for petrochemical plant construction. TRIS has supplied not only straight tubes but also Seamless Coiled tube with longer length. The seamless coiled tubes have many benefits with reducing welding pointsand minimized the leakage points and helping to reduce the construction period in dramatically. In 2013, TRIS developed the Seamless Coil Tube. Now, TRIS can handle various steel grades such as 904L, C-22, Incoloy825, Super Duplex etc. of Coiled Tube and Straight Tube. The longer length of Nickel alloy coiled tube is usedfor chemical injection, hydraulic control, gas detect line etc. in Oil & Gas industry. In addition to the heat exchanger tubes of TRIS of chemical plant used in severe environmentsprovide the most efficient operation conditions by stable quality control and various Ni alloys.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The versatility and and capability of LAWECO products is most notably shown in coil processing systems. In the infeed and outfeed areas, coil lifting carriages primarily handle the coil. In conjunction with various rack systems even complete solutions can be realised. In the stack areas, stationary and movable scissor lift platforms provide the required handling. Here, it is also our goal to respond to the wishes and requirements of our customers and to provide individual solutions. Coil weights up to 50 t With prism construction or support rollers With tilt-over protection tailor-made hydraulic group With materials handling technology, turntable / special construction With integrated weighing technology With special travelling gear With individual safety systems

Request for a quote

GSW SCHWABE AG

Germany

For onesided loading, GSW has five product series – and can thus answer basically any need in coil size, weight or width LHD, the light Coil Reel for up to 1 ton coil weight, with bevel gear expansion; LMHD, the light Coil Reel of our mid series for up to 1,5 ton, with lever arm expansion; MHD, the medium Coil Reel for up to 6 ton, with mechanical or hydraulic lever arm or key wedge expansion; SHD, the heavy Coil Reel for up to 25 ton, with hydraulic key edge expansion and SHZ, the twosided Coil Reel to handle heaviest and very wide coils. Performance data up to 30t coil weight and max 16mm material thickness max crosssection approx. 2000 x 5 mm max pulloff, decoiling or recoiling speed approx. 80 – 150 m/min

Request for a quote

HONSEL-GROUP

Germany

High-strength for design and repair Coil threaded inserts or “coils” are an outstanding solution for achieving highstrength joints in parts made from low-strength materials (e.g. aluminium lightweight constructions). At the same time, high wear resistance is guaranteed. Furthermore, the inserts are ideally suited for the repair of damaged threads. Very simple handling Coils consist of a specially formed and coiled wire with a driver pin that can be removed after installation and can be fitted quickly and easily in just a few steps. Choose the right threaded insert for your application from over 500 sizes. Do you need a special form? No problem! Together with you, we can develop the required coil threaded insert and produce it in the highest quality.

Request for a quote

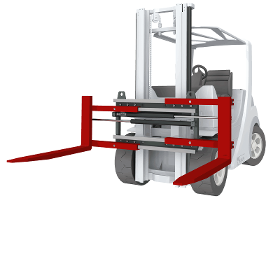

KAUP GMBH & CO KG

Germany

The KAUP hook-on Fork Positioner T411Z is a robust attachment for exceptionally heavy duty operation - ideal for uneven surfaces. Spreading forces induced, for example when handling coils (several) cable drums, rolls or wire coils, can readily be supported due to the large overlap of sectional profiles between fork guide and clamp body. Speedy working cycles and millimetre accurate positioning of the transport load is possible.

Request for a quote

SCHNELL SPA

Italy

Coil Flipper 3 is an efficient patented device for coil handling. Thanks to its innovative design, it can lift and rotate coils from the horizontal to the vertical position in one simple movement.

Request for a quote

SCHNELL SPA

Italy

Coil Mover is a safe and compact clamp for unloading trucks and handling coils in the factory. Thanks to its innovative shape, it allows the hooking of the rewinded coils from the inside.

Request for a quote

KEDY

Turkey

Lifting between 0-5 tons Hands-free operation Wide adjusting mechanism Safe and fast use with automatic lock mechanism No energy required CE certification The roll internal catching is inserted into the stocked roll horizontally, and the lifting process is performed with the "internal compression and bottom gripping method". The automatic locking mechanism is used while performing the transaction and can be used in a serial manner without the need for any outside intervention. It can be used to lift bobbins of any height with its height adjustment mechanism. It is used for transporting and stacking steel, sheet metal, paper and various round materials parallel to the ground. Stocking and shipping of sliced materials in sheet metal slitting plants always creates problems. Sliced roll materials are made horizontal by the tilting apparatus and placed on the pallets. Palletized horizontal rolls are made ready for shipment.As Per International Standard

Request for a quote

KEDY

Turkey

Introducing the K4300 C Hook for Lifting and Turning Coils from KEDY, the ultimate solution for handling large and heavy coils of materials in manufacturing and industrial settings. With a capacity of 3000 kg, this heavy-duty hook can easily lift and move large coils of materials with ease. The handle for the operator allows for safe and easy maneuvering of the hook and the material being handled. The K4300 C Hook for Lifting and Turning Coils is designed with a pivoting wedge feature that allows the operator to rotate the coil as it is being lifted. This makes it easy to handle and maneuver the material during the production process. The max. coil width of 300mm allows this hook to handle coils that are wider than standard sizes. Invest in the K4300 C Hook for Lifting and Turning Coils from KEDY and experience the efficiency and safety it brings to your material handling operations!

Request for a quote

KEDY

Turkey

The K4802 Manual Vertical Coil Lifter from KEDY is a manual handling device designed to lift and move large coils of steel, aluminum and other materials weighing up to 5 tons with an inner diameter range of 500mm to 600mm. It has two adjustable arms that are inserted into the center of the coil and locked in place for added safety. The operator simply moves the handle and the arms tracts onto the coil, allowing for easy lifting and movement with a crane. The K4802 is built to last with high-quality materials and construction, making it a durable and efficient tool for industrial settings. Contact KEDY to learn more about this product.

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band’s in-house slitting line offers the capability for slitting up to 1250mm wide coil x 0.20 - 1.50mm thickness in 304/316L/321 and 430/409. Other grades are available on request. Also offering material as PE or PVC coated/with foil. Coil sizes range from 200kgs to 3500kgs depending on final widths. This unique line means Stainless Band can handle coils up to 8.5 tonnes on-site made from stainless steel AISI 304/316. This will reduce pricing and also improve delivery times to clients for wide coil and also standard products that Stainless Band provide. They offer good formability, corrosion resistance, toughness and good mechanical properties. As a result they are widely used for insulation and engineering applications. These grades are non-magnetic in the annealed condition. The density of our wide coil is 8.03kg/cm3-0.29 Ibs/in3. The modus of elasticity is 200 Gpa.

Request for a quote

KEDY

Turkey

Introducing the K4201 Electric Coil Upender & Flipper & Tilter from KEDY - the ultimate solution for efficient and safe coil handling. With a weight capacity of 100 tons, this machine can upend coils in just 20 seconds and move them at the same time, which minimizes the process time for your customers. The polyamide pads ensure that the coils are not damaged during the handling process, and the limit switches provide added safety and automation capabilities. The K4201 Electric Coil Upender & Flipper & Tilter is a game changer in the industry, allowing you to move and upend coils at the same time, this means that it cuts the time required for the process in half. It's perfect for use in manufacturing and processing industries, and its automation capabilities make it a great choice for streamlining your operations. With its robust construction, reliable performance, and safety features, the K4201 is an excellent investment for any business looking looking to improve their coil handling!

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser is among the most experienced suppliers of presses and automation for sheet metal forming on the market. High precision, long lifetime of machine and tool, and low maintenance costs speak for the quality of our machines. ANDRITZ Kaiser produces customized solutions for every application – from the stand-alone press or roll feeder to complete production lines with coil handling equipment, finished part handling, scrap handling, and automation system. With over 8,000 automatic punching and metal forming presses worldwide, our customers produce high-quality formed and punched products. Our sheet metal forming solutions find applications in the automotive (OEMs and suppliers), white goods, electronics, electromotor lamination, construction, and consumer goods industries. Numerous well-known companies place their trust in our equipment. Our range of products Complete production lines for blank cutting, electromotor lamination, or conventional stamping Automatic...

Request for a quoteResults for

Coil handling - Import exportNumber of results

36 ProductsCountries

Category

- Lifting equipment (7)

- Machine tools, metal shaping - parts and accessories (6)

- Metal straightening machines (6)

- Industrial cutting machine tools (3)

- Coil winders (2)

- Stainless steels (2)

- Boilers, stainless steel (1)

- Buckets and grabs, crane (1)

- Building hand tools, non-power (1)

- Drums, barrels and kegs - metal (1)

- Forklift trucks (1)

- Nuts and bolts (1)

- Tanks, metal (1)

- Water purification - systems and equipment (1)

- Wine fermentation tanks (1)