- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- co-extrusion

Results for

Co-extrusion - Import export

LOUISON INDUSTRIES

France

Discover coextruded tape, used in the building and public works and agriculture sectors as reinforcement in a construction operation (e.g. reinforced earth, tutoring...). A combination of textile and plastic, coextrusion is a process that involves melting thermoplastic resins which then cover the textile in the form of threads (high-tenacity polyester threads, for example). Each material brings its own properties to the product. So, according to the specifications we receive, we will incorporate all the characteristics you need: resistance, texture, etc... Note: the plastic residues generated can be transformed into reusable beads, reducing the overall waste produced during the extrusion process.

Request for a quote

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

we can safeguard a very high level of process control in our extrusion production lines because our vulcanization process is done in a salt bath. This means the temperature of vulcanization is stable and independent of external conditions. This way, we can produce rubber profiles of a very consistent and high quality. Co-extrusion: we can produce 2 rubber types (eg hard and soft) into 1 final product High geometrical accuracy High surface quality Can be tailored to customers' needs Possibility to apply different types of coatings (our patented PPC coating, graphite coating or chlorinated).

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a Chinese plastic extrusion products manufacturer custom making PVC soft and hard co-extrusion profiles according to customer’s design or sample. we can co-extrude profiles by Soft and Hard Co-extruding, 2/3(double or three) colors Co-extruding, 2 materials Co-extruding. We are focus on plastic extrusion custom services for worldwide customers, and have produced more than Thousands of plastic profiles & pipes for foreign clients in the past 15 years. At the same time, we have gained a wealth of experience, and the requirements for product quality have further deepened our understanding. Plastic extrusion products mainly use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services.

Request for a quote

COLORSLED

China

6mm wide luminous surface, slim and delicate. Adopt silcone co-extrusion process, featured in strong bending and flexing resistance, can achieve various top bending styles. Small cutting unit, more precise size, more free design. Great protective performance with resistance against water, fire, aging and chemical corrosion. Innovative outlet solution, suitable for outline decoration of furniture and other installation applications

Request for a quote

COLORSLED

China

11mm wide large luminous surface, 120°beam angle. Adopt silcone co-extrusion process, featured in strong bending and flexing resistance, can achieve various top bending styles. Built-in COF LED strip, displays brilliant colors. Small cutting unit, more precise size, meet the requirements of dimension accuracy in project customization. Suitable for laminate furniture or display racks in shopping malls as display lighting

Request for a quote

COLORSLED

China

Ultimate slim, three side lighting. Anti-tensile, Strong bending resistance, Various top-bending stylings can be molded, Achieve your creativity worry-free and easily. Multiple voltages and colors optional,(White light, R/G/B options ) Silicone co-extrusion process, Up to IP65 protection level. Multiple accessories for widely applications.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Extrusion Coating EC Thermal Imaging System from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes.The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field

Request for a quote

KHARKIV HIMPROM LTD

Ukraine

The new range of COEX plastic bottles BP.0025 (250 ml), BP.005 (500 ml), BP.01 (1000 ml) is resistant to chemically aggressive substances and is suitable for agrochemicals (herbicides, pesticides, insecticides, etc.), auto chemicals, household chemicals and other substances based on organic solvents. The use of high density polyethylene with the polyamide protective layer manufactured by co-extrusion blow molding COEX allows to use of the canisters for liquids which cannot be filled into polyethylene bottles due to the rapid destruction of the container or due to diffusion of products through the packaging walls. We offer you to expand the range group and core audience for your product. The bottles supply around Ukraine, Europe, CIS and Russia is conducted by the qualified transportation companies. The bottles customer pick-up is possible from Vasishchevo, Kharkov region, Ukraine or from the warehouse in Belgorod, Russia.

Request for a quote

SCHAAF TECHNOLOGIE GMBH

Germany

Sweet creamy fillings in a moulded, crisp extrudate shell The latest in sophisticated products from direct extrusion are the co-extruded, centre filled products. In these products a soft filling with a pumpable viscosity is metered continuously, using a suitable pump, into an extruded pipe, simultaneously while it is being extruded. A special design co-extrusion die is used for this purpose. The result is an extruded pipe filled with a creamy mass. This pipe can then be moulded into various shapes continuously with the help of special moulding rollers. Raw-materials: It is important to choose a proper combination of the extrudate raw-materials and the filling mass in these kinds of products to ensure that they combine harmoniously in the final product to give a compatible eating experience to the consumer.

Request for a quote

KHARKIV HIMPROM LTD

Ukraine

The new range of COEX plastic bottles BP.0025 (250 ml), BP.005 (500 ml), BP.01 (1000 ml) is resistant to chemically aggressive substances and is suitable for agrochemicals (herbicides, pesticides, insecticides, etc.), auto chemicals, household chemicals and other substances based on organic solvents. The use of high density polyethylene with the polyamide protective layer manufactured by co-extrusion blow molding COEX allows to use of the canisters for liquids which cannot be filled into polyethylene bottles due to the rapid destruction of the container or due to diffusion of products through the packaging walls. We offer you to expand the range group and core audience for your product. The bottles supply around Ukraine, Europe, CIS and Russia is conducted by the qualified transportation companies. The bottles customer pick-up is possible from Vasishchevo, Kharkov region, Ukraine or from the warehouse in Belgorod, Russia.

Request for a quote

KHARKIV HIMPROM LTD

Ukraine

The new range of COEX plastic bottles BP.0025 (250 ml), BP.005 (500 ml), BP.01 (1000 ml) is resistant to chemically aggressive substances and is suitable for agrochemicals (herbicides, pesticides, insecticides, etc.), auto chemicals, household chemicals and other substances based on organic solvents. The use of high density polyethylene with the polyamide protective layer manufactured by co-extrusion blow molding COEX allows to use of the canisters for liquids which cannot be filled into polyethylene bottles due to the rapid destruction of the container or due to diffusion of products through the packaging walls. We offer you to expand the range group and core audience for your product. The bottles supply around Ukraine, Europe, CIS and Russia is conducted by the qualified transportation companies. The bottles customer pick-up is possible from Vasishchevo, Kharkov region, Ukraine or from the warehouse in Belgorod, Russia.

Request for a quote

KUZEY GLOBAL

Turkey

Kuzey has been successfully producing and developing sheet extrusion lines for many years, aligning with the latest technological developments. These lines include mono-layer, co-extrusion, and multi-layer systems, all of which are compatible with PP, PS, and PET raw materials.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

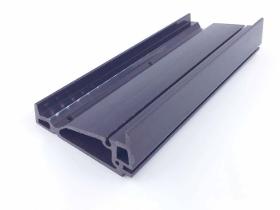

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. We provide a variety of extrusion process processing, cold extrusion, hot extrusion, two-color co-extrusion, three-color co-extrusion, soft and hard co-extrusion,can meet customer requirements of different products processing needs! If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. We provide a variety of extrusion process processing, cold extrusion, hot extrusion, two-color co-extrusion, three-color co-extrusion, soft and hard co-extrusion,can meet customer requirements of different products processing needs! If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. We provide a variety of extrusion process processing, cold extrusion, hot extrusion,Embossing Extruding, two-color co-extrusion, three-color co-extrusion, soft and hard co-extrusion,can meet customer requirements of different products processing needs! If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

TECHNIC MACHINES

Turkey

We produce our Co Extruder machines for different plastic extrusion solutions. Such as with different extrusion screw design, screw length and diameter range according to final product of our customers and requested capacity. Our co extrusion machine can work with different raw material such as PVC, PP, PE, TPO, TPE, TPU, EVA, PET, PS, WPC, ABS, HDPE, PC, TPR, PEX, PA, etc. We provide for our customers the optimum solutions according to their final product on our Coex extruder, according to requested raw material and capacity demand.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RHIMEX.COM

Netherlands

RENOVATION SEALS FOR WINDOWS AND DOORS Brush seals - Window seals - Sash rebate seals - Edge protection seals - Adhesive seals - Foam rubber seals - Steel frame seals - Door seals - U-profiles More than 2.000 profiles from EU stock. New tooling starting at EUR 95.- Delivery time 2/4 weeks. Several standard colours available. From 35 / 85 shore

Request for a quote

RHIMEX.COM

Netherlands

Profiles for Industrial Applications. In the large group of industrial applications (refrigeration and air-conditioning technology, machines, production lines, switchgear housings, wind power, tracked crane systems, containers, etc.) we produce individual sealing systems tailored to our customers’ needs. Special designs made on short notice--even in small series--made of diverse plastic or elastomer qualities, or combinations of both materials or assemblies lets us be your technical problem solver. Our huge stock of standard profiles makes us a reliable partner for a wide-range of applications. Sealing Profiles Through application-specific production of rings, frames or fixed lengths, the product is precisely tailored to any purpose. The function of the profile is optimally executed even in the radiuses or corners. We manufacture ready-made profiles in various processes, from cold bonding, film bonding, injection molding to sealing.

Request for a quote

FATRA A.S.

Czech Rep.

PVC granulate is a semi-product designed for further industrial processing (extrusion / co-extrusion, injection, moulding, coating). It is made from mixtures of plasticized / non-plasticized polyvinylchloride and respective admixtures according to final use requirements.

Request for a quote

PROEX PACK SP. Z O.O.

Poland

Shrink film is characterised by low sealing temperature, high tensile strength and very high transparency. Production range from 50 to 2500 mm in width. Thickness from 0.020 to 0.300 mm, made in three- layer co-extrusion technology. The hoods perform insulating functions. It is an ideal solution for the protection of materials, susceptible to all weather conditions such as moisture, dust or mud. Standard hoods – two side folds “Y” type hoods – one upper fold

Request for a quote

HEXPOL TPE GMBH

Germany

Thermoplastic elastomers are bonded to engineering plastics by melt adhesion to the most widely used structural plastics. Since the materials are bonded together at the production stage, no separate adhesive is needed, which makes the process faster and more cost effective than if the two parts were assembled together after each had been produced separately. There are two main processing procedures used to achieve bonding, overmoulding and co-extrusion. When overmoulding with soft components, the surface of the hard component softens and a diffusion of the molecules in the outer layer takes place. A prerequisite for this is that the two materials, i.e. the TPE Compound and the engineering plastic, must be compatible with one another, meaning that they must not reject one another’s molecules. As the molecule mobility increases, the molecules of the two materials will diffuse and this gives rise to so called melt adhesion. The molecules of the two materials form a network at the surfac

Request for a quote

HEXPOL TPE GMBH

Germany

Due to their efficient processing, high performance and recyclability, Dryflex TPE compounds have proved themselves as a quality replacement for vulcanised rubber in window and door sealing applications. Colour and co-extrusion have further enhanced the design possibilities. We develop custom formulated materials which deal with the design, performance and environmental needs of the future. Dryflex TPEs are totally recyclable and can be reprocessed and regenerated to produce functional gasket products. We have developed trade standard grades, including compounds developed to meet the requirements of BS 7412:2002 Class A or B standard and are suitable for ‘static’ (Class A) or ‘dynamic’ (Class B) applications. As well as grades that meet the requirements of RAL GZ 716/1, Class IV (and Class V) standard. Our Dryflex Extrusion range also includes translucent, foamable, rigid and semi-rigid compounds. Download the Dryflex Extrusion Profiles Product Guide

Request for a quote

STAMIXCO AG

Switzerland

StaMixCo manufacturers all three commercially proven static mixer designs used for high viscous melt flow mixing of polymers in extrusion service. As with most process equipment, each static mixer design has specific advantages and disadvantages that make it more or less suitable for a specific application and installation. Each type of motionless mixer is discussed below: Process Improvements: Temperature gradients are virtually eliminated. Viscosity gradients are virtually eliminated. Composition gradients of colorant, chemical additives, fillers and regrind are virtually eliminated. Stagnant polymer wall-creep material is incorporated into the bulk polymer stream. Extrusion Applications Static Mixers are used in most extrusion applications including the following: Sheet Blown Film Foam sheet Profile extrusion Co-extrusion Pipe Extrusion Blow Molding Rod & Tubing Wire & Cable Coatings Fiber extrusion & monofilaments Benefits Reduction of color additives with comparable extrudate color density. Even thickness across the entire extrudate width. Streak-free product. Improved quality when using regrind material. Foam cell size and cell distribution uniformity. Improved surface quality Improved mechanical characteristics. Rapid color change-over SMB-R Static Mixer SMB-GXS Static Mixer Mixing of blue and white epoxy resin with the SMB-GXS Static Melt Blender. It improves the melt homogeneity by factor 5-6. SMB-R Static Mixer The SMB-R static mixer for extrusion service (licensee of Bayer AG, Leverkusen, Germany) contains eight (8) very efficient motionless mixing elements that homogenize the polymer melt as it enters the extruder die. The SMB-R mixing elements are considered as high performance design where they create a very high degree of mixing in a short length. The SMB-R mixing elements are virtually indestructible due to their monolithic cast construction where the mixing bars are jointed to each other and to the ring wall via a single molten metal pour. Mixing of blue and white epoxy resins. Empty tube (top)provides no mixing. Eight (8) mixing elements (bottom) provide an excellent mix quality in a short length. SMB-GX Static Mixer Melt Blender The SMB-GX motionless mixer is a design that has been used in melt flow mixing extrusion service for over 25 years. The SMB-GX mixing elements are considered as high performance design where they create homogeneous mix in a short length. It has the same fundamental X-Grid crossing-bar structure as the StaMixCo SMB-R static mixer (Figure #8), but without the support ring around the mixing blade structure which gives the SMB-R its remarkable strength. Since the SMB-GX is manufactured from metal plates that are welded together, virtually any custom static mixer plate thickness, material and diameter can be fabricated to meet process and installation requirements. SMB-H Static Mixer Melt Blender The SMB-H Helical static mixer design pioneered the static mixing industry and has been used as a viscous static mixer on extruders for over 37 years. The Helical design is considered a low mixing performance-long length-low pressure drop motionless mixer as compared to the later developments of high performance static mixers such as the SMB-R and SMB-GX which have become the technology standards in the industry. StaMixCo manufactures SMB-H static mixers by advanced proprietary manufacturing technique where the entire unit is machined from a solid rod of bar stock material without welding. This machining process allows for custom static mixer fabrication in virtually any L/D twist, in very small sizes, with very high strength, straight and true dimensioning and with a RMS 12 mirror polish surface finish which is a much improved surface finish as compared to the traditional 32 RMS finish for the twisted and welded design.

Request for a quote

POLIFILM GMBH

Germany

In addition to adhesive coated protection films, POLIFILM is also offering coextruded, uncoated yet self-adhesive films since more than 12 years. These protection film solutions combine the film manufacturing process (film extrusion) and the adhesive extrusion in one process. The traditional process requires typically at least 2 steps. This co-extrusion process presents a clear productivity gain also for our customers. We develop co-extruded protection films together with our partner, who has a long time experience in the development and production of cast films. Our joint technological experience presents an ideal platform for the development of ever more demanding requirements of our customers now and in the future.

Request for a quote

WUXI KAIJINHUA PLASTIC INDUSTRY CO.,LTD

Belgium

The scraps of TPE/TPV vacuum forming carmats can be 100% directly reused after being crushed, and the cost of vacuum forming processed mats is cheaper than injection molding. As people's requirements for environmental protection are getting higher and higher, TPE/TPV car floor mats have gradually replaced traditional rubber, PVC or EVA floor mats, occupying the mainstream market. In order to save costs, our company has developed an ABA three-layer co-extrusion sheet extruder. Among them, layer A is TPE/TPV surface layer material that is easy to process and demoulding, and the middle layer of layer B is TPE/TPV material with low cost.

Request for a quote

WUXI KAIJINHUA PLASTIC INDUSTRY CO.,LTD

Belgium

We have produced POP display profile extrusion machine for more than 10 years. And our machine occupied the majority of market share in Changshu and Jiashan city. Besides, we also export to Russia, India,Vietnam, South Africa, Thailand etc. Our company have experience of producing 2 extruders and 3 extruders co-extrusion display profile machine. Till now , we produced many kinds of display profile including card holder,display clip,data strip,shelf barker,corner gripper etc. Compare with other manufacturer, our machine advantage is High production speed, and low input.

Request for a quote

FLEXPLAS

Turkey

Cutting-edge FLEXT Series Extruders Flexplas proudly offer a wide range of FLEXT Series Single-Screw Extruders, either as a stand-alone extrusion machine or as part of a complete extrusion-system. All Flexplas extruders are characterized by an open, robust, and proven construction and high-quality craftsmanship. Screw diameters from 20 to 120 mm and process lengths of 25D to 30D combined with the appropriate screw geometry guarantee excellent plasticizing and maximum output for all popular thermoplastics. Digital, self-optimizing PID temperature control and a blower cooling system ensure outstanding process stability. Other features include Sliding hopper, ceramic heaters, screw designed for every type of material, energy-saving system, digital extruder control with touch screen. Flexplas FLEXT-series extruders boast many a feature as standard. We also present various customized options for our customers to meet their production requirements.

Request for a quote

PIRLANT RUBBER PROFILE

Turkey

EPDM Solid 70 Shore EPDM Sponge 0,55 gr / cm3

Request for a quoteResults for

Co-extrusion - Import exportNumber of results

31 ProductsCountries