- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cnc pipe bending machine

Results for

Cnc pipe bending machine - Import export

TECHNIC MACHINES

Turkey

The main advantages of our CNC tube bending machine are the most advanced software and the perfect mechanical construction, which has been developed with over 30 years of experience. If you are an experienced user of tube bending machines, you definitely know the importance of the machine body construction and software in a CNC tube bending machine. General Details of the CNC Tube Bender: - PC-Based Control – Ethernet - CNC Bender Simulation Function - Automatic, Semi-Automatic, or Manual Control - Possibility of Mandrel-Free Bending - Production Quantity Parameters on the Screen - Error Messages on the Control Panel Screen - Maximum Diameter Range from 6 mm to 130 mm Ø - Spring Back Correction in the Software - Elongation Correction in the Software - 3D File Reading - Possibility of Manual Programming - Possibility of Automatic Programming - Warning Function in the Simulation

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Stable, flexible and economical. This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of highvalue components ensure the machine's durability.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most extreme geometries on tubes. With our clockwise/counterclockwise bending machines – also available with push bending function – the most complex bends become reality with great accuracy.

Request for a quote

TECHNIC MACHINES

Turkey

We designed our Semi-Automatic Pipe Bending Machines to have complex pipe bending results easily with servo rotation function during pipe bending process. We can say that our Semi Automatic Tube Bending Machine is economical option of 3 Axes CNC Pipe Bending Machines with lower investment than CNC Tube Bending Machine. General Details - Servo Rotation - NC Control - Direct Gear Transmission - Touch Screen - Hydraulic Clamp-Die/Pressure-Die - Automatic Mandrel Extraction - Adjustable Flip Stops - Quick Changeable Tooling - Automatic / Manual Mode - Warning Messages - Energy Saving Mode Technical Details Tube Bending Diameter Range from 6 mm to 130 mm Ø Pipe Bending Machine Center Line Radius According to Demand Max. Tube Bending Angle 190°

Request for a quote

AMOB UK

United Kingdom

Our CNC Pipe Bender CH series is the backbone of our tube and profile bending machines. Their rigidity, stability and untouchable precision in exceptional conditions such as humidity or harsh temperatures is what makes them stand out from the crowd. Ranging from 6mm up to 420mm OD these pipe bending machines are adapt for use in a wide range of pipe manufacturing sectors and industries. The range includes the fully CNC pipe bender version, for wich all three axis are automatic in a single stack machine. There’s also the option to add welding detection, punching/cutting mechanisms and integrated loading and unloading systems if necessary. The CH series tube bending machine come equipped with the AMOB NC touchscreen easy-to-operate controls, or in the CNC version, the latest user-friendly AMOB 3D bending software. So, this stores tooling configuration, allows spring-back compensation and boasts anti-collision technology, amongst other features.

Request for a quote

FHM METAL ISLEME

Turkey

We produce up to 25 diameters for our valued customers with CNC Pipe Bending Machine.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Multidimensional and automated bending of tubes. Highly efficient CNC bending technology for small and big bending tasks with the greatest precision. Our fully automated solutions mean optimum cycle times and large production volumes. The outstanding flexibility of our advanced CNC tube bending machines gives you economical bending process and meets the most demanding requirements. The solution for the future: highly dynamic and flexible, thanks to the 100 % servo-electric technology. For tubes with diameters from 1/4" to 6". The DB CNC VE series are absolute powerhouses of machines. They can bend tubes in round, oval, square, rectangular, and other special profile shapes. In addition, they are known for outstanding rigidity and power which is unmatched in the market for this size of machines.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

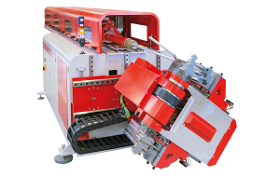

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quoteResults for

Cnc pipe bending machine - Import exportNumber of results

40 ProductsCompany type