- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cnc milling centres

Results for

Cnc milling centres - Import export

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

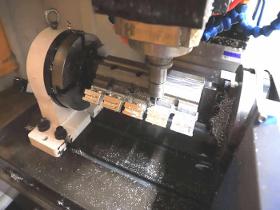

Aluminum Milling Components by CNC machining centre Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Brass Parts by CNC Turning & Milling on machining centre Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Aluminium Components by CNC Milling on Machining centre Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

Aluminium Parts milled on CNC machining centre Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

5-axis/5-sided machining means the C 42 lends itself to be used in every application area. With traverse paths adapted to the workpiece size and perfectly designed for 5-axis applications, the C 42 is ideal wherever complex, close-tolerance components are required. This includes various applications in the tool and mould making, medical, aerospace, motorsport, machine sectors and other industries: The C 42 machining centre is at home in every area. The space-saving circular tool magazine integrated into the base body of the machine works according to the pick-up principle - thus enabling quick tool changes. In the standard version, the C 42 can hold 42 tools and can be extended to 192 pockets. The control panel can be easily adjusted to the respective user. Milling and turning in one clamping with the C 42 U MT dynamic model. Fully integrated rotary table that does not interfere with demanding milling processes and 5 axes simultaneously.

Request for a quote

OFFICINE BELLUCCI SRLS

Italy

DENVER ADVANCE PLUS – Year 2019 Vertical CNC Work Centre Edging, Drilling, Milling Min. Dimensions 550 x 170 mm Max Dimensions 3500 x 1500 mm Max Weight Sheet 150 Kg Thickness 4-21 mm Power 15 kW Spindle Working Hours 4837

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -For horizontal & vertical usage-suitable for CNC controlled milling machines & large machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely -Gripper studs suitable for materials with a strength of up toapprox. 1000N/mm² Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -Fully compatible with the accessories of the LC/TC 160 series, for example gripper studs, universal gripper set & pull down sets -Grounded sides so that all sides can be used High-pressure spindle with mech. force amplifier for the safe clamping of raw parts in combination with gripping & pull down spring function -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Milling black anodized aluminum enclosure

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC machining stainless steel 304 part

Request for a quote

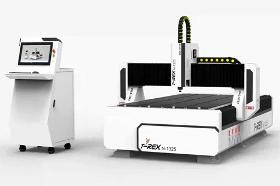

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Milling black POM Part

Request for a quote

TARHAN AUTOMATION AND MACHINE

Turkey

Cutting and Drilling : We produce cutting and punching machines that can perform product-specific cutting and punching of rubber, plastic, aluminum and steel materials, either simultaneously or separately.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours.

Request for a quote

VIRMER

Netherlands

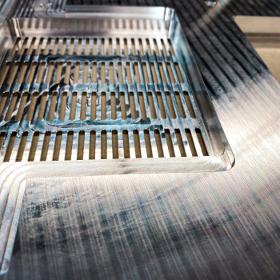

WATTSAN M1 2030 wide-format machine has a large working area of 2000×3000 mm with a slatted table top. The design includes a spindle with an ER-25 collet chuck and a power of 6 kW. An air cooling system and a built-in vacuum cleaner for collecting wood chips and dust are also available for an additional fee. The leadshine 860 stepper motor driver is responsible for moving the portal, the machine is controlled by the operator through NcStudio. The body of the machine is a welded structure made of steel profile, the weight of the machine is 1400 kg. The maximum travel speed along the axes is 25 000 mm/min, the maximum travel speed during operation is 15 000 mm/min. The spindle speed reaches 24 000 rpm. If you want a more upgraded machine, we can install: Vacuum table. DSP controller. Syntec control system. chip removal system. manual auto lubrication. more powerful spindle or additional cutting heads. rotary device for processing cylindrical products. tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М9 1325 has a working area of 2500х1300х200 mm and a T-slot slatted table. The complete set of the machine includes a water-cooled spindle with the power of 7.5 kW and ER-32 collet chuck. The portal is driven by YASKAWA servomotor and steppers. The milling machine is controlled by an operator through Weihong NCStudio control system. Unlike the junior model, this machine supports the automatic tool change option. The machine body is a welded structure made of steel profile; the weight of the machine is 1500 kg. The maximum travel speed along the axes is 50 000 mm/min; the maximum travel speed during operation is 20 000 mm/min. The spindle speed reaches 24 000 rpm. The machine is controlled by NCStudio software. On request, the machine can be equipped with a vacuum table, a DSP-controller, a Syntec control system, an aspiration system, a more powerful spindle or an additional spindle, a rotary device to process cylindrical objects, and a tool sensor.

Request for a quote

VIRMER

Netherlands

Wattsan M4S milling machine with 4 spindles is intended for continuous material processing. Working spindles are changed automatically that significantly facilities the operator’s work. Spindles have power of 6 kW and come with an ER-32 collet chuck. Only one spindle can be in operation at a time. The working area is 1300x2500 mm. The processed material is fastened by the vacuum table. Pneumatic stops and a vacuum table make setting of the material on the table fast and accurate and facilitate double-sided or straight-line processing

Request for a quote

VIRMER

Netherlands

CNC wood milling machine WATTSAN M1 1325. Ideal for rapidly starting production. Despite the fact that the model belongs to the CNC wood router machine for beginners, complex products are made with this machine. WHY YOU SHOULD BUY THIS CNC WOOD ROUTER MACHINE 1) Solid cast iron frame ensures reliable and high processing accuracy. 2) It is possible to complete the machine with a 4th rotary axis. 3) Attractive to entrepreneurs starting their business as it is easy to use and quickly pays off. The Shimpo planetary gears enable the machine to process even hard metals with high constant precision. Heat treatment of the frame relieves stress from the metal - this is done in every Wattsan CNC machine designed to process wood. This ensures long-term operation while maintaining the accuracy and rigidity of the structure. Work area = 1300*2500 mm Spindle power = 4,5 kW Controller = DSP A11 Weight = 690 kg Machine size = 2000*3040*1780 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN М1 1616 belongs to М1 series, that is considered more technically sophisticated than A1 series and has a massive frame. The frame is more stable and allows process more complex parts. The machine is applicable for cutting of wood, MDF, chipboard, acryl, plexiglas, PVC, aluminum, composite. Using WATTSAN М1 1616 you can also perform a 3D milling. WATTSAN М1 1616 has a grid type working table of 1600×1600×300 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. Max speed of movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 18 000 rpm. The machine controlled by NC-Studio control system. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

CNC milling and engraving machine WATTSAN A1 1616 is a cost efficient, easy-to-use and multi-purpose equipment. The machine performs a cutting and engraving, also WATTSAN A1 1616 can perform a 3D milling. WATTSAN A1 1616 has working area of 1600×1600×200 mm, spindle ER-25 with power of 2.2 kW, water cooling system. The portal is moved by step engine controlled by driver Yako 2405. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 500kg. Max speed of spindle movement along axis is up to 25 000 mm/min, max working speed is 15 000 mm/min. Spindle rotation speed can reach 24 000 rpm. The working table has a T-slot grid plate. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN М1 1313 has a grid type working table of 1300×1300×200 mm, but additionally we can install a vacuum table, that holds the sheet material in place and significantly ease the process. The construction includes a spindle ER-25 with collet and power of 2.2 kW, water cooling system. The portal moved by step engine driver Leadshine 860. Operator controls the machine with control system NC-Studio. Frame of the machine is welded from steel profiles construction; weight of the machine is 700kg. Max speed of spindle movement along axis is up to 25 000mm/min, max working speed is 15 000mm/min. Spindle rotation speed can reach 24 000 rpm. We can modernize the machine with the following: vacuum table, DSP controller, chip removal system, automatic lubrication, more powerful spindle or additional cutting heads, rotator for cylinder shaped parts, tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN A1 1313 machine has a working field of 1300×1300×200 mm, an ER-20 spindle with a power of 2.2 kW, and a water cooling system. A stepper motor controlled by the Yako 2405 driver is responsible for moving the portal. The body of the machine is a welded structure made of steel profile, the weight of the machine is 500 kg. The maximum travel speed along the axes is 25,000 mm/min, the maximum speed in operation is 15 000 mm/min. Spindle speed can reach 24000 rpm. The table has a slatted T-slot cover. The machine is controlled by NcStudio software. To upgrade this machine, we can install: vacuum table. DSP controller. Chip removal system. Manual auto lubrication. More powerful spindle or additional cutting heads. Rotary device for processing cylindrical products. Tool sensor.

Request for a quote

VIRMER

Netherlands

WATTSAN M1 6090 machine has a working field of 600×900×200 mm with a slatted table cover. A spindle with an ER-20 collet chuck and a power of 1.5 kW, together with a water cooling system (for stable operation of the machine) are included in the basic package. The body of the machine is a welded structure made of steel profile, the weight of the machine is 500 kg. The maximum movement speed along the axes is 25000 mm/min, the maximum speed in operation is 15000 mm/min. Spindle speed can reach 25000 rpm. The machine is controlled by NcStudio software. To upgrade this machine, we can install: DSP controller.

Request for a quote

VIRMER

Netherlands

CNC wood milling machine WATTSAN A1 6090. Ideal for rapidly starting production. Despite the fact that the model belongs to the CNC wood router machine for beginners, complex products are made with this machine. WHY YOU SHOULD BUY THIS CNC WOOD ROUTER MACHINE 1) Solid cast iron frame ensures reliable and high processing accuracy. 2) It is possible to complete the machine with a 4th rotary axis. 3) Attractive to entrepreneurs starting their business as it is easy to use and quickly pays off.

Request for a quote

VIRMER

Netherlands

WATTSAN 0609 mini Desktop cnc wood milling machine WATTSAN 0609 mini for processing materials on a small area. Ideal for rapidly starting production. Despite the fact that the model belongs to the cnc wood router machine for beginners, complex products are made with this machine. The rigid frame of the machine and cast iron side posts allow the gantry clearance to be increased up to 450 mm, while the Shimpo planetary gears enable the machine to process even hard metals with high constant precision. Heat treatment of the frame relieves stress from the metal. This ensures long-term operation while maintaining the accuracy and rigidity of the whole equipment.

Request for a quote

VIRMER

Netherlands

Desktop cnc wood milling machine WATTSAN 0404 mini for processing materials on a small area. Ideal for rapidly starting production. Despite the fact that the model belongs to the cnc wood router machine for beginners, complex products are made with this machine. WHY YOU SHOULD BUY THIS CNC WOOD ROUTER MACHINE 1) Solid cast iron frame ensures reliable and high processing accuracy. 2) It is possible to complete the machine with a 4th rotary axis. 3) Attractive to entrepreneurs starting their business as it is easy to use and quickly pays off

Request for a quote

AHP PLASTIK MAKINA

Turkey

The test bar milling machine enables bar-shaped plastic samples to be produced for tension, pressure, bending and flexural impact tests in accordance with a wide range of standards. According to ISO 6259 , ASTM D 638 , ASTM D 1822 , ISO 16770 , 3 axis desktop CNC, cutting tensile samples from plastics, computer controlled, G-codes for samples according to customer request

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

CNC 5 axis milling of aluminium, brass, steel, plastics etc. at our Datron ML1500-4 (workspace XYZ 1500 x 2000 x 240 mm), Datron ML1600 (workspace XYZ 1600 x 2500 x 240 mm), Datron MLCube (workspace XYZ 1500 x 1000 x 245 mm) and Datron M8Cube (workspace XYZ 1000 x 800 x 245 mm)

Request for a quote

BIESSE UK

United Kingdom

WinLine 16 is Biesse's new NC multi-centre for the production of doors and windows, designed for artisans and small industries aiming to increase production and for medium and large industries who need to produce small batches of unusual size or remakes. The system produces both standard and special doors and windows with the utmost simplicity while the operator handles other tasks; the machine only takes up a small area and handles the loading, unloading and positioning of pieces autonomously and with extreme precision.

Results for

Cnc milling centres - Import exportNumber of results

29 ProductsCompany type

Category

- Milling - machine tools (13)

- Milling - steels and metals (6)

- Mechanical engineering - custom work (2)

- Glass manufacturing - machinery and equipment (1)

- Machine tools - metal machining (1)

- Milling and turning of rubber and plastic (1)

- Stainless steels (1)

- Steel & Metal Transformation (1)

- Steels and metals - machining (1)

- Testing equipment (1)

- Woodworking - machinery and equipment (1)