- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping units

Results for

Clamping units - Import export

EWS WEIGELE GMBH & CO. KG

Germany

Mount tools safely and in the correct position while remaining flexible, all this is possible with the UMB100 mounting unit. The tool clamping units can be changed quickly, making the system an ideal mounting aid for multi-tasking machines. It only takes a few seconds to replace an adapter. The unit with snap-in swivel can be pivoted 4 x 90° at the touch of a button so that even angled holders can always be mounted in the ideal position. Universal mounting block UMB100 Tool holder for VDI holding fixtures Tool holder for Varia VX Tool holder for steep-angle taper holding fixtures

Request for a quote

SITEMA GMBH & CO KG

Germany

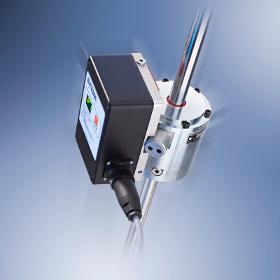

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

NORELEM FRANCE

France

1. Screw the locking screw into the collar bush, fixture clamp and clamping unit and screw onto the baseplate. 2. The workpiece is clamped by tightening the fixture clamp with a spanner. Advantages: Compact design Quick and easy clamping of components Pull-down effect Drawing reference: 1) Locking screw 2) Collar bush 3) Fixture clamp 4) Clamping unit

Request for a quote

NORELEM FRANCE

France

The UNI lock mounting clamps can be installed in any position on machine tables, fixtures or workholding equipment (tooling plates, cubes, tombstones etc). The modular design enables the number of clamps and distance between them to be ideally adjusted to suit the clamping task. The clamps can be supplied with or without rotation lock. The high clamping forces are generated by the integrated spring package (the unit clamps when depressurised). Compressed air is applied to release the clamp. The following holding forces are possible with the UNI lock clamping bolt in conjunction with M10, M12 or M16 fastening screws: Holding force (M10) 35,000N Holding force (M12) 50,000N Holding force (M16) 75,000N Supplied with: 1x clamping module incl. 6 fastening screws. 6x screw protection caps. 2x air connection O-rings. 1x installation O-ring.

Request for a quote

NORELEM FRANCE

France

Completely mounted multi-clamping stations with integrated UNI lock Ø138 mm mounting clamps. The clamping stations are secured to the machine table directly or with clamps. Common bore patterns are pre-centred on the rear side for mounting. Clamping stations can be aligned via the 14H7 reference holes. The clamping stations are actuated via a central pneumatic connection. The high clamping forces are generated by the integrated spring package (the unit clamps in the de-pressurized state). The release process occurs pneumatically. The following retaining forces are possible with the UNI lock clamping bolt in conjunction with mounting screws M10, M12, M16: Retaining force (M10) 35,000N/module Retaining force (M12) 50,000N/module Retaining force (M16) 75,000N/module

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping with bellows sealing Modular unit designcustomer taylered configuration, fast and economic cartridge fast change CDcartridgedesign sealingmaterial ceramics/graphite. For coking heat transfer oil with temperature higher than 230 °CVersion HT with diamondhard sealface and hightemperature graphitesealring graphite bushbearingsmaintenance free no elastomerstherefore no temperature and chemical resistance problems no loose parts, f.e. springs robust and less influence of dirty media self supportingno additional support necessary available in stainless steel PRESSURE MAXIMUM 6,0 bar air heat transfer oil 10,0 bar steam 17,0 bar water TEMPERATURE MAXIMUM 175 °C air 190 °C steam 300 °C heat transfer oil SPEED MAXIMUM 250 1/min DN 100 (4") 300 1/min DN 65 (2 1/2") DN 80 (3") 400 1/min DN 50 (2") SIZEDN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4")

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quote

GSW SCHWABE AG

Germany

Special Reels are a longtime part of the GSW lineup Our Horizontal Reels (also called “Pallet Decoilers”) for instance, are helping to unwind lying coiled materials. They are best suited for thin strip which often is loaded together with the carrier pallet. GSW Tilting Reels make sense where normal coil loading is difficult or the materials don’t allow that process. Instead, the coil is loaded horizontally and uncoiled vertically afterwards. Paper Winders help to safely process paper interleaf or film coatings innovative expansion and clamping units help for quick and simple handling. Performance Data up to 3t coil weight and max approx. 2mm thickness max crosssection 300 x 2mm max winding or payoff speeds approx. 20 – 100m/min

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 420 - for tube-Ø from 4-20 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 660- for tube-Ø 6 - 60 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 645 - for tube-Ø 6 - 45 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

FÖHRENBACH GMBH

Germany

The rotary table combination RT3A100 consists of two directly driven rotary tables of the RT3A100 series. The B-axis has a swivelling range from approx. -10° to +110°; the C-axis can be rotated infinitely. The unit is driven by two integrated 3-phase synchronous motors. The drive guarantees highest dynamics and precision. An innovative clamping unit integrated in the housing guarantees high holding forces when the drives are switched off without position changes on the axes. By means of compressed are impact, the holding torque can be increased from 15Nm to 20Nm for special applications. The complete system is supplied as ready-to-connect unit.

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping with bellows sealing Modular unit designcustomer taylered configuration, fast and economic cartridge fast change CDcartridgedesign sealingmaterial ceramics/graphite ballbearings (can be relubricated) no elastomerstherefore no temperature and chemical resistance problems no loose parts, f.e. springs robust and less influence of dirty media self supportingno additional support necessary available in stainless steel PRESSURE MAXIMUM 6,0 bar air heat transfer oil 10,0 bar steam 17,0 bar water TEMPERATURE MAXIMUM 190 °C air heat transfer oil nontoxic gases steam vacuum water SPEED MAXIMUM 500 1/min NPT thread 800 1/min ISO 228 thread SIZEDN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4")

Request for a quote

NORELEM FRANCE

France

UNI lock double clamp modules are particularly suitable for the direct clamping of workpieces. Workpieces with complex geometry can be completely machined on 4 and 5 sides. UNI lock double clamp modules can be mounted in any position. The high clamping forces are generated by the integrated spring package. (the unit clamps while not pressurised). Clamping is released pneumatically. The following clamping forces are possible with the UNI lock clampng pin in conjunction with M10, M12, M16 fastening screws: Clamping force (M10) 35,000 N Clamping force (M12) 50,000 N Clamping force (M16) 75,000 N Supplied with: 1 double clamp module incl. 3x pneumatic connections.

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

universal usecooling, heating, clamping with bellows sealing Modular unit designcustomer taylered configuration, fast and economic cartridge fast change CDcartridgedesign sealingmaterial ceramics/graphite. For coking heat transfer oil with temperature higher than 230 °CVersion HT with diamondhard sealface and hightemperature graphitesealring solid grease ballbearingsmaintenance free no elastomerstherefore no temperature and chemical resistance problems no loose parts, f.e. springs robust and less influence of dirty media self supportingno additional support necessary available in stainless steel PRESSURE MAXIMUM 6,0 bar air heat transfer oil TEMPERATURE MAXIMUM 300 °C air heat transfer oil vacuum SPEED MAXIMUM 250 1/min DN 100 (4") 300 1/min DN 65 (2 1/2") DN 80 (3") 400 1/min DN 50 (2") SIZEDN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4")

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JET FLOW TECHNOLOGIES UK LIMITED

United Kingdom

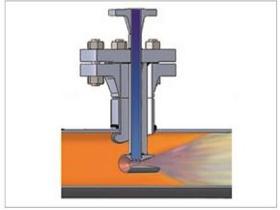

A version of single venturi desuperheater has the same operating conditions. can be mounted easily and quickly in the exisiting pipeline. The unit can be clamped between two flanges. Sizes are between 1 1/2” to 30”

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic mitre bandsaws from BEHRINGER are saws to really get things moving. Particularly when it comes to classical series production such as cutting to fixed lengths and mitre sawing in automatic mode. And also when cutting layers and packages they make a good impression. By their excellent cutting performance and short nonproductive times, your productivity can be increased significantly. Using an NC controlled feed gripper in conjunction with an NC controlled saw frame mitre box, fully automatic mitre cuts can be performed on both sides. The PC control system provided as standard makes for extremely simple menu-prompted operation of the saw and peripheral devices. The BEHRINGER mitre bandsaws contain many useful features already in the basic price: - Convenient PC control - Fast NC-controlled mitre system - Vertical clamping unit - NC-controlled feeding gripper with 3.000 mm feeding length in single stroke - Spray mist cooling system

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This equipment now permits fittings up to 3“ to be inserted or extracted. Due to its innovative rapid tool sled, the insertion of 90 degree, 45 degree or straight fittings without changing tools is now simple and quick. Ergonomic Freely positional foot pedal for clamping hose saves time and increases productivity Lifting eyes for easy positioning of the machine Simple to use Universal hose clamping jaws for all hose diameters without the need for changeover eliminates lengthy setup times Axially adjustable clamping unit for all diameters prevents kinking of thin hoses and for efficient operation Individual clamping force adjustment for damage-free clamping avoiding scrap Zero maintenance and wear contributes to cost savings Rapid sled for inserting curved and straight fittings without time-consuming exchange of fork sets saves time Safety compliant Moving components have safety guarding CE-compliant, robust UNIFLEX quality

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Semi-automatic machines for single cuts and small seriesWith automatic saw feed and quick-clamping device for the material, the semi-automatic models offer higher cutting output levels and more operating convenience than the manual saw variants. By ensuring fatigue-free working for the operator, they are also suitable for sawing small production runs: Quick-acting pneumatic / hydraulic clamping device Clamping pressure reduction available as option Variable hydro-pneumatically / hydraulically controlled setting of the saw blade feed Easy miter cutting positioning with fixed stop Easy stroke adjustment of the saw unit via 2 clamping levers Well dimensioned worm gear unit with EISELE shock-absorbing feature Quick and easy blade change

Request for a quote

OMS MEKANIK OTOMASYON SISTEMLERI SANAYI TICARET LIMITED SIRKETI

Turkey

Cap tightening machines are designed to be able to tighten all caps between 10 mm and 50 mm Air system motor is used in cap tightening machines. The systems work with air. 7-8 bar air pressure is needed for the system. According to the condition of the products, a holder can be added for round bottles so that the bottle does not rotate. It can be deactivated in square bottles. Cap squeezing apparatus can be changed according to the bottle cap types. It performs the lid tightening process between 1500-3000 hours depending on the product lid. Cover clamping units are controlled by plc system and 10-7-4.3 hmi screen when they are alone. It can be added to the filling system when used with the filling line. It can use the same screen with the filling system.

Request for a quote

INO MACHINERY

Turkey

ino XP 8000 is a Gantry type 4 axis CNC machining center for processing profiles. The Maxi-Steel type of extra strengthened machine body has a huge rigidity and flexibility in processing profiles of 350 mm X 350 mm in 0,1 mm / 1-meter precision and 80 mt./min X-Axis speed. With the heavy body and the gantry type of machining bridge, it is possible to process the heaviest aluminium profiles, even hardened steel and stainless steel profiles. The clamping units are moved automatically by the column, and the data is collected from the 3D CADCAM profile machining software that generates G codes from the profile drawings. All profile data can be imported from dxf and dwg files very easily through the software. The machining operations can be programmed by using the ready macros for drilling and milling. The machine has a 7.5 kW 24.000 rpm spindle with adjustable speed for different thicknesses of materials.

Request for a quote

INO MACHINERY

Turkey

The Compact Design CNC profile machining center with 4 controlled axes X-Y-Z-A. The machine is mainly designed for processing aluminium profiles. Apart from aluminium, it can also process any light alloy profiles with the help of dedicated customized cutters. The bridge carrying the high-speed electro spindle moves on linear guides by the brushless servo motors independently from the drive and processes any shape on the profiles. The electrospindle can rotate from 0 to 180 degrees independent from the drive and machine in any angular position and change the tools from the tool changing magazine with 7 positions. The CADCAM software is a customized tool for “ino machinery” profile machining centers. The pneumatic reference point tilts up and down automatically according to the machine’s working cycle.4 pieces of profile clamping units are positioned manually by the operator according to the places that the CADCAM decides.

Request for a quote

EKO WELDING & MACHINE AUTOMATION SYSTEMS

Turkey

There are hydraulic pressing clamps in the fixture equipment of system. The workpiece is both made spot welding by means of clamps and prevented distortion due to heat during welding. Separate control lever is used as to be put to rear of piston for each piston.Also there is a pressure relief valve on each control lever. Thanks to pressure relief valves the critical pressure is brought to the desired pressure and the compression of the material in desired strength may be achieved A lock valve is connected to each hydraulic cylinder after the tightening process and during the welding operation, the material is prevented from being retracted and opened due to heat input. Reverse deflexion may be done on the frame thanks to the control units in the clamp mechanisms. 1 inert gas arc welding machine will be used for spot welding process.( it will be supplied by the purchaser)

Request for a quote

FILLTECH GMBH

Germany

The profiFill 4.0 is a highly flexible filling solution for CO 2/N 2O or mixed gasses. Through a pre-programmed filling process, which can be easily configured, adjustable individual solutions and consistent documentation can be ensured. The ProfiFill station is a universal filling station. No matter what cylinder your market requires, our equipment can be adapted to your needs. A clamping unit ensures safe and ergonomic filling. Highlights Ergonomic, durable, fast Lifting unit for short cylinders Pneumatic valve open/close unit Maintenance-free DryLin T-Linear guiding 4 load cells for precision and easy calibration Pneumatic filling head Legal for trade Technical Data: Weighing range: 0-150kg / 0-330lbs. Filling range: 6-50 kg / 0-330 lbs. Cylinders: up to 300 x 1800 mm / 11.8 x 70.8 in. Dimensions: 910 x 800 x 2300 mm / 35.8 x 31.5 x 90.5 in. Weight: approx. 300 kg /661 lbs. Weight Scales & Controls 999 storable cylinder types (PLU) Automatic filling process; automatic closin

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Filling and mixing lines: Filling and mixing line, height and laterally adjustable Filling and mixing line, with removable mixing nozzle Mixing tube made of hard PVC, rotatable with 1 pipe clamp Filling and mixing line, galvanised steel, can be rotated using socket spanners, height and laterally adjustable mixing nozzle Mixing tube made of completely from hard PVC with flange connection with 1 pipe clamp Mixing tube made of completely from hard PVC with flange connection, height and laterally adjustable mixing nozzle with 1 pipe clamp Mixing unit completely galvanised, rotatable, height adjustable with clamp bracket and flange connection Mixing tube completely galvanised with flange connection, mixing nozzle, height and depth adjustable Mixing nozzle completely galvanised with flange connection, fixed mixing nozzle Tank filling line completely galvanised, fixed mounting, 360 degrees rotatable with flange connection Coupling parts,...

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

The ASEPTconnect Inline unit allows to install measuring instruments into pipes taking all requirements related to successful SIP and CIP procedures into account. The instrument connection is designed as Aseptic clamp connection per DIN11864-3, model A. Inline unit with aseptic clamp-connection per DIN 11864-3, model A (groove side), dead-zone free ■ Process connection: pipe ends or clamp-connection ■ Seals gap-free by means of an O-ring ■ Fast and accurate mounting of the devices ■ Various pipe diameters available ■ Hygienic design ■ Suitable for CIP or SIP procedures ■ Pipe ends suitable for orbital welding ■ Delta ferrite content < 0.5 %

Request for a quoteResults for

Clamping units - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Clamp collars, plastic (4)

- Metallurgy - machinery and installations (4)

- Electric motors and parts (3)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Pipes and tubes - ferrous metal (2)

- Sawing machine tools (2)

- Bottling and filling - machinery and equipment (1)

- Hydraulic equipment (1)

- Laser - cutting and welding machines (1)

- Measurement - Equipment & Instruments (1)

- Mechanical engineering - custom work (1)

- Metal straightening machines (1)

- Milling - machine tools (1)

- Rolling machines (1)

- Steam turbines (1)