- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping bushings

Results for

Clamping bushings - Import export

NORELEM FRANCE

France

These centring clamps enable workpieces to be centred on and lightly clamped in a bore. The clamps have a wide expansion range. The series covers a bore range of Ø12 to Ø30 mm. To increase the centring accuracy the clamps with internal thread have a centring spigot (D2) for a locating hole. The centring accuracy is ±0.2 mm. Centring clamps with female threads fit on M6 grid systems (see illustration).

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

BO-QA Clamping bushings Pulleys can be fastened to cylindrical shafts or journals safely, flexibly and, above all, economically with BOQA clamping bushings. Shaft-to-hub connections with BOQA fastening elements are: SAFE - non-positive, backlash-free and highly precise fastening of pulleys FAST - marked gain in time needed for assembly FLEXIBLE - wide range of applicability, high delivery standard ECONOMICAL - reduction in costs SPACE-SAVING - extremely compact, no overhang NON-CORROSIVE - made predominantly of stainless steel Shaft-to-hub connections with BOQA fastening elements are insensitive to extreme load alternations. They can be easily adjusted axially and radially, are easy to mount and dismount. Any additional forming of the shaft or other adjustment work will not be necessary.

Request for a quote

NORELEM FRANCE

France

1. Screw the locking screw into the collar bush, fixture clamp and clamping unit and screw onto the baseplate. 2. The workpiece is clamped by tightening the fixture clamp with a spanner. Advantages: Compact design Quick and easy clamping of components Pull-down effect Drawing reference: 1) Locking screw 2) Collar bush 3) Fixture clamp 4) Clamping unit

Request for a quote

NORELEM FRANCE

France

Standard HTD profile with metric pitch (rounded toothing). At least one toothed belt pulley must have a rim flange. Conical hole for taper clamping bushes. The taper clamping bushes must be ordered separately and are available for various shaft diameters. Pulleys with a taper hole are statically balanced as per ISO 1940 grade G16.

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer in compact design with one-sided actuating rod; long life span and high adjustement speed; Flexible mounting via clamps, bushing mounts or flange plates

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Potentiometric position transducer in compact design with one-sided actuating rod and return spring; long life span and high adjustement speed; Flexible mounting via clamps, bushing mount or flange plates; probe tip with pressed-in hardened metal ball

Request for a quote

NORELEM FRANCE

France

1. Screw the locking screw into the collar bush and fixture clamp and screw onto the baseplate. 2. The workpiece is clamped by tightening the fixture clamp with a spanner. Advantages: Compact design Quick and easy clamping of components Drawing reference: 1) Locking screw 2) Collar bush 3) Fixture clamp

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Light Clamps – the clever plastic series: With the plastic tube connectors from the "Light Clamps" series, RK Rose+Krieger has developed a cost-effective and versatile range of tube connectors for the positive connection of tubes in the light load range. This design enables the clamping of the most various tube sections and –diameters. Besides their attractive design and the intelligent system of reducing bushes the clamping elements are characterised especially by their resistance to chemicals. They are particularly appropriate for sensitive applications under laboratory conditions and for industrial applications as, for instance, in the beverage or packing industry.

Request for a quote

APD MAQMASTER

Spain

Hydropneumatic cutting process. Safe cutting with double spring system and disc guard. Vertical and horizontal pneumatic clamps. Shock resistant cast iron bushing. Cut at any angle between -45º and +45º. Cutting speed adjustment according to the profile. Cut with fixed angle of 0o, 15o, 22.5o, 30o, 45o to the right and left. Ø 400 mm disc. Cooling system. OPTIONAL Roller road. Single-phase system.

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

The Eltex cable rewinders are the optimal accessory for our grounding devices or, in the passive version, also as a simple grounding cable reel for safe storage of the grounding cable and the grounding clamp. In addition to the well-known 601KR/BW passive rewinding cable reel with 9 m grounding cable in a plastic casing, the new 601KR/EW rewinding cable reel is available in an impact-resistant aluminum casing and can hold a grounding cable of up to 12 m. These reels can be used in Zones 1 and 21. Both reels are designed for wall mounting, but the 601KR/EW can also be swivel-mounted using a mounting bracket. A coupling plug can be used to easily connect the passive 70SG and 70PK clamps with the coupling bushing of the grounding cable.

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

Series SKR-K with cone clamping bush Series SKR-N with keyway connection robust slide bearing for high bearing forces and best concentricity compact attachment and optimum pane integration

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

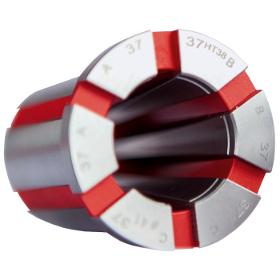

The segmented clamping bushing SE with the hexagon socket sits on the clamping pyramid, absolutely form-fitted in every clamping position and thereby enables maximum machining performance with minimal vibration and thus less tool wear. The full-surface contact of the segmented clamping bushing on the mandrel ensures a significantly better insensitivity to contamination than previous segmented clamping bushing/mandrel systems. Therefore, these segmented clamping bushings are even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. And they offer this suitability at run-out of ≤ 0.01 mm and in the premium version at ≤ 0.007 mm.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

In terms of precision, stability, and flexibility the vulcanized segmented clamping bushings are unbeatable. They consist of segments made of chrome/nickel, case hardened steel that is very hard, extremely wear resistant, and rigid [60 HRC]. Plus, they do not have to »bend« to clamp the workpiece. In addition, all functional surfaces are completely ground in one clamping set-up. The result: maximum run-out accuracy, maximum holding power, and long life span.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Maximum machining capacity MAXXOS T211 is a mandrel with a hexagonal pyramid shape instead of a round taper – perfect for demanding and reliable process manufacturing. Through the hexagonal clamping pyramid, maximum transmission forces can be realized. The segmented clamping bushing with the hexagon socket sits on the clamping pyramid with an absolute positive fit, which enables maximum machining capacity with less vibration and thereby less tool wear. The lubrication, combined with its leak-tightness ensures an extremely constant production flow and therefore maximum reliability. By the way, our segmented clamping bushings offer a factory-standard run-out accuracy of ≤ 10 μm. If you need even greater precision, there are two additional levels of run-out quality to choose from. Even a run-out accuracy of ≤ 2 μm is possible upon request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Whether lathe or machining center Complete machining made easy: You cannot only use our MANDO and MAXXOS segmented mandrels on the lathe, you can also use them in stationary mode. Simply screw the mandrel onto the ms dock [manually actuated] or hs dock [hydraulically actuated] and you can clamp your workpiece from the inside, stationary mode. Precise, without vibration and with minimum set-up effort. The extremely wear-resistant segmented clamping bushing of case-hardened chromium-nickel-steel with the rubber between the segments, especially developed by HAINBUCH, makes it possible. Manual actuating unit ms dock The hand-actuated ms dock in conjunction with stationary MANDO and MAXXOS segmented mandrels is ideal for machining centers, measuring machines, radial drill presses, parallel and angle plate clamping or for clamping on dividing heads. The version ms dock rotating can be used on turning and grinding machines until RPM 1/min.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Made for the gear-cutting sector Clamping solutions for the gear-cutting sector are individual and have very special requirements. Consequently, it is not easy to find the suitable clamping device, particularly in the case of high variant diversity and smaller lot sizes. The conventional solution is to use fixtures that are more or less effective. Rigid and narrow standard segmented mandrel Fortunately, this is now history. With the MANDO G211 you are relying on a standard segmented mandrel. You profit from in-stock segmented clamping bushings. The rigid and narrow mandrel with optimized tool runout contour is ideal for use in gear cutting applications. Moreover, it can also be used for gear shaping or grinding. Three end-stop levels that are placed with different proximity to the workpiece make it possible to use individual workpiece end-stops. Also a coolant connection ensures process reliability.

Request for a quoteResults for

Clamping bushings - Import exportNumber of results

20 ProductsCountries

Company type

Category