- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tube support

Results for

Tube support - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

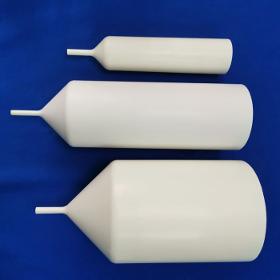

Porous ceramic rods description: Porous ceramic filter rods are composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. * Good electrical insulation * High dimensional tolerances * Excellent corrosion resistance * Very high working temperatures * Excellent thermal shock properties Applications of Alumina Porous Ceramic * Furnace work tubes * Kiln furniture, components & accessories * Thermocouple protection tubes * Heater Support Elements

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

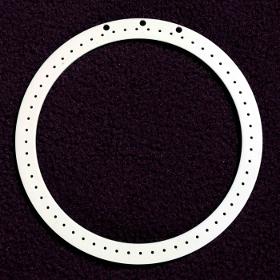

Porous ceramic plate is composed by the distributed evenly open pores which is interconnected by shape like arch , when the fluid through these pores,the suspended matter, colloidal particles, organic molecules are trapped, adsorbed inside the micropores,then track to achieve the purification and filtration homogenizing effect. The porous ceramic has the advatage with high strength, wear resistance, high temperature, corrosion, pollution, porosity distribution, long service life and easy to regenerate, which is particularly suitable for a variety of gas, liquid filtration and fluidized process. Applications of Alumina Porous Ceramic * Furnace work tubes * Kiln furniture, components & accessories * Thermocouple protection tubes * Heater Support Elements * High Temperature Electrical Insulators * Extreme temperature measurement components * Ceramic Laser components * High voltage electrical insulators

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Pyrolytic boron nitride is a grade of hexagonal boron nitride. It is produced by chemical vapor deposition process to create its solid body and all the boron nitride crystals grow parallel to the surface of which the vapor is deposited on. Due to the nature of CVD process, PBN parts generally are requested the wall thickness not more than 3mm. PBN is also a good choice for extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process give this pyrolytic boron nitride almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. PBN Ceramic Applications: -Crystal growth (VGF, LEC Crucible) -Molecular Beam Epitaxy(MBE) Crucible -MOCVD Heater -PBN Infrared Window -Traveling Wave Tube (TWT) (PBN Support Rod) -PBN Coating Graphite -High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Mechanically durable and thermally shock resistant, PBN/PG heaters are unaffected by vibration under most conditions and can be tailored to thermal gradients for specific requirements. With an ultra-fast response and low thermal mass, PBN/PG heaters demonstrate a power output of 35 watts/cm 2 (225 watts/in 2 ) and higher.Size customization, please let me know the use temperature, current and voltage. -Crystal growth (VGF, LEC Crucible) -Molecular Beam Epitaxy(MBE) Crucible -MOCVD Heater -PBN Infrared Window -Traveling Wave Tube (TWT) (PBN Support Rod) -PBN Coating Graphite -High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Pyrolytic boron nitride is a grade of hexagonal boron nitride. It is produced by chemical vapor deposition process to create its solid body and all the boron nitride crystals grow parallel to the surface of which the vapor is deposited on. Due to the nature of CVD process, PBN parts generally are requested the wall thickness not more than 3mm. PBN is also a good choice for extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process give this pyrolytic boron nitride almost perfect layered structure, which leads to nisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. PBN Ceramic Applications: -Crystal growth (VGF, LEC Crucible) -Molecular Beam Epitaxy(MBE) Crucible -MOCVD Heater -PBN Infrared Window -Traveling Wave Tube (TWT) (PBN Support Rod) -PBN Coating Graphite -High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Due to the nature of the CVD process, PBN parts generally are requested a wall thickness not more than 3mm. PBN is also a good choice for the extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process gives this pyrolytic boron nitride an almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. Pyrolytic Boron Nitride Applications: Crystal growth (VGF, LEC Crucible) Molecular Beam Epitaxy(MBE) Crucible MOCVD Heater PBN Infrared Window Traveling Wave Tube (TWT) (PBN Support Rod) PBN Coating Graphite High temperature, vacuum equipment insulator

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tube support - Import exportNumber of results

6 ProductsCountries

Company type

Category