- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- substrates

Results for

Substrates - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

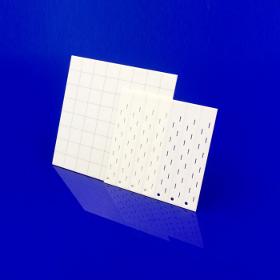

The Aluminum oxide (Al2o3) 96% ceramic plates are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Name:Aluminum Nitride Ceramic Substrate, AlN Ceramic Sheet Application:Often used in electrical and electronic fields requiring heat conduction, heat dissipation, insulation, high temperature resistance,high voltage breakdown resistance, high thermal conductivity, good stability. Product specifications: Conventional models are TO-220, 247, 264, 3P Range thickness: 0.25mm, 0.385mm, 0.5mm, 0.635mm, 0.8mm, 1mm, 1.5mm, 2mm, 3mm Product Advantages: Aluminum nitride ceramics have excellent thermal conductivity (7-10 times of alumina ceramics),low dielectric constant and dielectric loss, reliable insulation performance, excellent mechanical properties, non-toxic, high temperature resistance, chemical corrosion resistance, and the thermal expansion coefficient of silicon is similar, as a new generation of ceramic materials, more and more by people Attention and attention.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DPC (Direct Plated Copper) Mainly by evaporation,magnetron sputtering and other surface deposition process to carry on the substrate surface metallization,first under the condition of vacuum sputtering,titanium,and then is copper particles,the plating thickness,then finish making line with ordinary PCB craft,and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating,wet deposition,Exposure development, etching and other processes. Advantages: >In terms of shape processing, DPC ceramic plate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. >The crystal performance of the metal is good >The flatness is good >The line is not easy to fall off >The line position is more accurate,the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3 96%) ceramic substrate are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. The Maximum dimension of ceramic plate is 138x138mm and the thickness of ceramic plate ranges from 0.25 to 1.0mm. Alumina Ceramic Substrate Features: > High reliablility and sfety; > High density and mechanical properties > High electrical and thermal loading perormances > Low dilelectic loss and other characteristics Alumina ceramic substrate / plate specification: 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Factory Custom Silicon Nitride Thermal Substrate for High Power Radiator Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

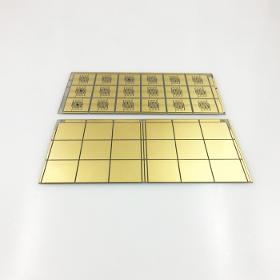

DBC (Direct Bonded Copper) tenique denotes a special process in which the copper foil and the al2o3 or AlN (one or both sides) are directly bonded under appropriate high temperature. The finished super-thin DBC substrate has excellent electrical isolation,high thermal conductivity, fine solderability and high bonding strength.It may be structured just lick PCB to get etched wiring and has high curreng loading capability .Therefore DBC ceramic substrates have become the base material of tuture for both the construction and the interconnection techniques of high power semiconductor electronic circuits and also have been the basis for "chip on boaed" technology which repre-sents the packaging trend in century. Specification >Metallization thickness: 25 ±10um >Nickel thickness:2~10um >Pin full strength: 4200kgf/cm2 avg. (at Φ3.0mm pin)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum nitride ceramics have excellent electrical and thermal properties, and are considered to be the most promising high thermal conductivity ceramic substrate materials. In order to seal the package structure, mount components and connect input and output terminals, the surface and interior of the aluminum nitride ceramic substrate need to be metallized. The reliability and performance of ceramic surface metallization have an important impact on the application of ceramic substrates, and firm bonding strength and excellent air tightness are the most basic requirements. Considering the heat dissipation of the substrate, it is also required to have high thermal conductivity at the interface between the metal and the ceramic. The metallization methods on the surface of aluminum nitride ceramics include: thin film method, thick film method, high melting point metallization method, electroless plating method, direct copper cladding method (DBC), etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

No other oxide ceramic material collectively exhibits these highly desirable properties and characteristics. BeO ceramic conducts heat more quickly than virtually all metals with the exception of copper and silver. Beryllia exhibits extremely low dielectric loss characteristics, possesses high electrical resistivity, and offers excellent strength with high specific stiffness properties. BeO provides all the desirable physical and dielectric characteristics exhibited by an aluminum oxide or aluminum nitride, in addition, offers thermal conductivity ten times higher than alumina, and fifty percent higher than aluminum nitride, a dielectric constant that is lower than both alumina and aluminum nitride, and weight per given volume that is fully a quarter less than alumina, and nearly ten percent less than aluminum nitride. As a thermally conductive and electrically insulating material, its performance is exceeded only by that of the diamond.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DBC ceramic substrate: Direct bonded copper (DBC) substrates are commonly used in power modules, because of their very good thermal conductivity. They are composed of a ceramic tile (commonly alumina) with a sheet of copper bonded to one or both sides by a high-temperature oxidation process (the copper and substrate are heated to a carefully controlled temperature in an atmosphere of nitrogen containing about 30 ppm of oxygen; under these conditions, a copper-oxygen eutectic forms which bonds successfully both to copper and the oxides used as substrates). The top copper layer can be preformed prior to firing or chemically etched using printed circuit board technology to form an electrical circuit, while the bottom copper layer is usually kept plain. The substrate is attached to a heat spreader by soldering the bottom copper layer to it. 1. Thickness of substrate can be thin: 0.25mm,0.28mm,0.45mm,0.5mm,0.635mm,1.0mm,1.5mm, 1.8mm,2.0mm 2.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3 ) ceramic rectangle substrate is widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

At present, conventional insulation materials have disadvantages such as low temperature resistance, low purity, gas release at high temperature, poor toughness, no insulation at high temperature, and easy to be corrosed. PBN insulation board can solve these problems. Main Features: 1. The maximum tolerance is 2300℃ in vacuum and 2700℃ in ammonia atmosphere; 2. High purity, high temperature does not release gas impurities (>99.99%); 3. Good toughness (hexagonal structure similar to graphite); 4. High temperature insulation (volume resistivity 3.11×1011 ω •cm); 5. Intensification of inert, acid, alkali, salt and organic solvent corrosion; 6. Low thermal conductivity in the DIRECTION of C can block the downward conduction of heat and reduce heat loss PBN Plate Applications: For vacuum, high temperature, MBE equipment and other fields of insulation gasket, gasket, support, etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o396%) ceramic substrate are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. The Maximum dimension of ceramic plate is 138x138mm and the thickness of ceramic plate ranges from 0.25 to 1.0mm. Features: 1.High reliablility and sfety; 2.High density and mechanical properties 3.High electrical and thermal loading perormances 4.Low dilelectic loss and other characteristics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

DPC Ceramic Substrate Advantages: > In terms of shape processing, DPC ceramic substrate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. > The crystal performance of the metal is good; > The flatness is good; > The line is not easy to fall off; > The line position is more accurate, the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Hot Press Boron Nitride Sheet Thickness 2 mm, 3 Square in stock (25 x 25 mm, 50 x 50 mm, 200 mm x 240 mm), custom size is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride: 1.High thermal conductivity 2.Low thermal expansion 3.Good thermal shock resistance 4.High electrical resistance 5.Low dielectric constant and loss tangent 6.Microwave transparency 7.Non toxic 8.Easily machined — non abrasive and lubricious 9.Chemically inert 10.Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quoteResults for

Substrates - Import exportNumber of results

16 ProductsCountries

Company type