- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing sheet metal

Results for

Processing sheet metal - Import export

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Laser cutting bending aluminum sheet metal parts

Request for a quote

RPWORLD

China

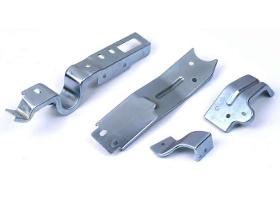

Stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the sheet metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging and coining etc. What Are the Manufacturing Processes of Stamping? Bending - the sheet metal is deformed or bent along a straight line. Flanging - the sheet metal is bent along a curved line. Embossing - the sheet metal is stretched into a shallow depression. Used primarily for adding decorative patterns.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Custom metal stamping parts FRIMA is the professional custom metal stamping parts manfacutrer. During the metal stamping process, blanks or coils of sheet metal feed through one or more die and tool sets. These die and tool sets form and cut the sheet metal into its desired shape.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Deep Drawn Parts – Quality Dee Drawing Service Ming Xiao Manufacturing Co., Ltd specialize in custom deep drawn parts more than 10 years, it’s made by hydraulic pressure machines or punch machine. material can be stainless steel 201, 304,316 and stainless iron, carbon steel, copper, Aluminum, etc. finish can be polishing, plating, powder coating, painting, etc. Deep drawing is the punch will move onto the flat sheet metal into the mold cavity in the cold forming process. Different from other drawing process, drawing a deep degree can pull more than its original diameter billet. Deep drawing technology in the production process is widely used. Drawing used in many industries. For example, you can use in the automotive industry in the production of automotive parts; also be used to manufacture household products, such as stainless steel kitchen sink,enclosure,console box or cover,motor shell… Welcome contact with us discuss your sheet metal deep drawn parts.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Fine blanking is a special processing of precision sheet metal stamping. Including powerful blanking precision blanking, opposing die blanking and flat blanking precision blanking. The geometric shape, dimensional tolerance, shape tolerance and shear surface quality of fine-blanking parts are much higher than those of ordinary blanking parts. Fine-blanking technology plays a very important role in the field of automobile parts manufacturing. There is an essential difference between the process characteristics of fine blanking and ordinary blanking. Normal blanking controls the tearing of the sheet during the blanking process, while fine blanking tries its best to suppress the tearing of the sheet during the blanking. The fine blanking is always kept as one body before the parts are separated from the sheet material, and the metal sheet is always in the plastic deformation process during the fine blanking process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GZ GUANGLI EFE CO., LTD.

China

Features 1.All steel construction raised basement; 2.Full downdraft airflow style, ensuring turbulence-free airflow path; 3.Illumination brightness reaches 1200 lux; 4.Oil fuel heating (gas-fired heating, electric central heating, hot water heating and steam heating are optional); 5.Sheet metal is processed to European standards; Standard Configurations -Basement: all steel construction raised basement, 5-row grating; -Fan unit: one 7.5kw intake fan, one 7.5kw exhaust fan; -Heating: Riello RG5D burner, with heat exchanger; -Lighting system: upper lights are 14*4*13W LED light tubes, lower lights are 10*4*13W LED light tubes; -Wall panel: sheet metal is molded by one-step process, four-side edge banded rockwool insulated wall panel, thickness 50mm -Ceiling structure: 14 pieces of precision punched steel panels -Roof panel: double-skin insulated roof panel -Electric control: imported electrical components, phase loss protection, overheat protection and overload protection

Request for a quote

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD offers sheet metal fabrication and pre-assemblies services as the complementary of our one-stop manufacturing service. The core benefits of this process include one-stop service, wide materials selection, hardware inserts, and our extensive experience in applications. - Wide Material Selection Aluminum, brass, copper, steel, tin, nickel and titanium. For decorative uses, important sheet metals include silver, gold, and platinum. - Hardware Inserts Choose from hundreds of in-house hardware inserts specifically designed for sheet metal fabrication. - One-stop Service Maintain consistent part quality and guaranteed lead times under our one-stop service. - Rich Experience for Various Applications Auto parts, medical devices, home appliances, robotics, scientific instruments etc. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

We offer cleanout set. Plumbing cleanout is a cleanout fitting with a removable plug that is found in a roughed-in waste system. It is designed to help keep clear any type of debris that could cause any type of stoppage in the water drain lines. Cleanout sets are usually placed at the connection point between the sewer lines and the drain lines where the base is located of a vertical stack, and at all places were the pipe direction changes at about 90 degrees. Material: Products are available in Stainless Steel AISI 304 (EN 1.4301) / AISI 316 (EN 1.4401 / 1.4404), Chrome plated Brass, Nickel Bronze Sizes: Currently sizes available are 200X200mm, 150X150mm 100X100mm, 80X80mm etc. Special sizes can be made as per your requirement.Finishes: Various finishes are available like MATT, MIRROR, and SATIN Fitment: It slips snugly into the drainage pipe and is easy to install. Cleanouts can be designed to fit various pipes. Designs: Various types of sizes and designs are available.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg engaged in Turning Parts custom machining services more than 20 years, we have old lathe turning machines, automatic turning machines, and CNC turning machines,Longitudinal lathes (CNC PRECISION AUTOMATIC LATHE). We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a China manufacturer specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in sheet metal Stamping services more than 20 years,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We are also have 6 sets different sizes progressive die stamping machines, can produce small metal stampings with high speed and low prices. suitable to high volume metal stamping components. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in sheet metal Fabrication & Stamping services more than 20 years,have been customized many kinds of sheet metal Casing,Enclosure,Bracket,Plate,Decoration Panel for different industries. We providing various processes such as punch Laser cutting,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Sheet Metal Fabrication Products Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishes: Anodize,painting,powder coating,blackening,electroplating of chrome/zinc/nickel /tin/silver... sales@mxmparts.com +86 13780014913

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg is a processional sheet metal Stamping Parts manufacturer from China,have been customed many kinds of sheet metal stamping parts, puched parts,deep drawn parts for different industries.We providing relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. Metal Stamping Parts Available Materials: Aluminum,copper/ brass,stainless steel, carbon steel, Mild steel,cold roll steel, Kovar steel,etc. CRS (cold rolling steel) sheet, HRS (hot rolling steel) sheet,hot-galvanize steel sheet (SGCC,SPCC,). stainless steel: 201,304,316... Aluminum alloy: 1060,2024, 3003,5052,6061,etc All standard brass and copper Finishs: Anodize,painting,powder coating,blackening,electroplatings of chrome/zinc/nickel /tin/silver... sales@mxmparts.com WhatsApp:+86 13780014913

Request for a quoteResults for

Processing sheet metal - Import exportNumber of results

15 ProductsCountries

Company type