- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packer

Results for

Packer - Import export

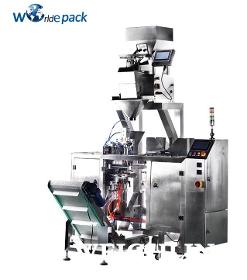

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

The product is suitable for fast and efficient packaging of chilled fresh meat, cooked meat products, cheese, soy products, aquatic products, poultry meat, etc. It has the characteristics of keeping food quality, fresh and shape. Packaging advantages:Improve the appearance value, strong three-dimensional effect, transparent and beautiful, easy to touch and inspect, and neat and beautiful.The product is fastened to the pallet, which can be shockproof, anti-friction, and anti-scratch; and vacuum-sealed, which can prevent moisture and oxidation, protect the quality of the product and prolong the shelf life.Compared with traditional packaging, its appearance display and shock protection effect are greatly improved, which enhances market advantages, expands sales opportunities, creates real value, and enhances brand influence.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with servo auger/agitator feeder system,30-50L fillers,and lifting conveyor,accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design ,compact and reasonable arranged in the smallest amount of space,to automatic control of a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.Adopt Siemens PLC control system, touch screen can set variety of languages,simple operation, and easy maintenance. 4.The machine use premade pouch,you have more choice for the bag type and excellent appearance .Sealing good, the finished product looks high-end. 5.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 6.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with liquid pump cylinder measurement,accurate measurement, fast speed, low defective rate, low noise,add the reflow system can avoid liquid material leakage. 2. Eight stations rotary design to automatic control of a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5.Modular heating, more accurate temperature control, heating failure can alarm prompt. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary pouch bagging vacuum packaging machine combine with different fillers,such as weighing machine,liquid pump and auger/agitator fillers, accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design to automatic control a series of processes from bag-giving,coding,bag-opening,filling,vacuuming,sealing,and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials.Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids. 3.Adopt Siemens PLC control system, be easily performed operation and maintenance. 4.Filling machine rotates intermittently to fill the product easily and vacuum machine rotates continuously to enable smooth running, it means high performance and high durability.All grippers width of filling machine can be adjusted at once by a motor but all grippers in the vacuum chambers are no need to adjust.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1. Rotary packing machine combinate with the multi-heads weighing machine, Z-type conveyor, platform, accurate measurement, fast speed, low defective rate, low noise. 2. Eight stations rotary design to automatic control a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5. The lifting system is suitable for a wide range of industries, like food fodder, chemical, and so on granule material packing. 6. Strictly follow the mechanical standards to production, ensure the quality, reduce late wear, and reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

Do you sell or make similar products?

Sign up to europages and have your products listed

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Equipped high-quality performance various weight filler and mini doypack machine with auto ziplock opener and output conveyor, date printer as an option for solid granules, powder, liquid, paste, etc. Apply for different premade pouch types, such as Custom Packaging Styles flat Bottomed Pouch, Stand Up Pouch, Quad Seal Bag, Flat Pouch – 3 Side Seal Bag, Shaped Pouch, Retort Pouch, Kraft Paper Bags. Bulk material feeding conveyor as an option available Various weight fillers such as auger filler, multi-head, linear, pump filler, etc. Supporting stand Mini Doypack Machine Output conveyor Metal detector and weight checker as option

Results for

Packer - Import exportNumber of results

7 ProductsCountries

Company type