- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metals and alloys

Results for

Metals and alloys - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Medical CoCrMo dental casting metal alloys 1.Product Introduction Cobalt & Nickel based alloys (non-precious) are used in the dental industry for making dental prosthesis. They are an economical alternative to Gold & Silver based alloys (precious) but perform well due to their mechanical properties and biocompatibility. 2.Chemical Composition Co Cr Mo C Mn Si Fe Other 60-62 29-31 5-6 0.55-0.65 ≤0.8 ≤1 ≤1 ≤0.5

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: Carbon steel: S235JR, S355JR,C45 Stainless steel: SS303, SS304, SS316L Non-ferrous metal: Brass, Alu, Ti alloy Plastic: POM, PP, PE, ABS Process: Turning/Milling/CNC Boring/Drilling/Threading Grinding Application: Agricultural machinery General machinery Hydraulic cylinders Telecommunication

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Mo Mn Ceramic Feedthrough Ceramic Vacuum Electrodes The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher. Advantages of Ceramic-to-Metal Seals * More solid, durable hermetic seal and better electrical insulation * Used for more harsh conditions, such as high and low (cryogenic) temperature, corrosive, high pressure, and high vacuum environments * High mechanical strength, less fracture when applied to high vibration and high g-load conditions * Shows strong bond and an excellent seal with metals and alloys, such as copper and Cu alloys (CuNi) and to nickel and Ni alloys.

Request for a quote

RAYUEN PACKAGING CO.,LIMITED

China

small cosmetic spatula made by metal material zinc alloy, which can be used as a beauty tool to apply face cream, facial mask to face, a brand logo can be printed or engraved, customized color can be made as per request.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Tube Components Manufacturer Custom Metal Tube Handles Of Aluminum Alloy, Carbon & Stainless Steel Tubes Tube end forming: A forming process used to create a specific end, usually to allow the tube to connect to another media. Cutting: The cutting process allows for metal tubes to be cut into specific shapes and sizes. Examples include tube laser cutting and mechanical cutting. Notching: This process creates notches at the end of the tube to simplify welding processes or to attach the tube to another part. Swaging: Swaging uses a die to manipulate the size of the tube diameter using force. Custom Metal Tube Forming Components, Seat Frame, Tube Handle, Yacht barrier... sales@mxmparts.com

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RAYUEN PACKAGING CO.,LIMITED

China

Description: high quality metal beauty spatula made from zinc alloy which is smooth and bright, as luxury cosmetic tool for applying eye care products and massage for better absorption. Use for: mainly used for applying face cream, eye cream, facial mask Decoration is available: customized color (glossy or matte), printed or laser engraved logo, etc.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Brass Forging Parts is a metal alloy that consists primarily of copper and zinc. The mechanical properties of brass depend on percentage of zinc along with several additional elements, which can vary significantly. Brass is harder and has a lower melting point than copper, but it has excellent working properties and is excellent for many end usesOrdering brass bar stock to the specified alloy composition in one of the many forms and shapes available is the typical first step in the process. Saw cutting provides blanks, sometimes called slugs, that then enter the forging or forming process. Some grades of brass alloy may be processed at room temperature, but it is most common for slugs to be heated to improve formability. Temperature for hot forging is usually in excess of 1000 degrees F but both the alloy and complexity of the configuration will determine the exact process requirements. In the forging process, the cut slugs are placed between dies and force

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

1.Size:24 x 6.5 x 2.4 cm 2.Material: Metal+aluminum alloy+stainless steel 3. Accessories: ear needles 4. Application for cattle/pig/sheep and other animal ear marking with ear tag applicator

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

1.Size:24 x 6.5 x 2.4 cm 2.Material: Metal+aluminum alloy+stainless steel 3. Accessories: ear needles 4.Weight:346g /1 piece 5. Application for cattle/pig/sheep and other animal ear marking with ear tag applicator

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

1.Size:24 x 6.5 x 2.4 cm 2.Material: Metal+aluminum alloy+stainless steel 3. Accessories: ear needles 4.Weight:346g /1 piece 5. Application for cattle/pig/sheep and other animal ear marking with ear tag applicator

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

1.Size:24 x 6.5 x 2.4 cm 2.Material: Metal+aluminum alloy+stainless steel 3. Accessories: ear needles 4.Weight:346g /1 piece 5. Application for cattle/pig/sheep and other animal ear marking with ear tag applicator

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

1.Size:24 x 6.5 x 2.4 cm 2.Material: Metal+aluminum alloy+stainless steel 3. Accessories: ear needles 4.Weight:346g /1 piece 5. Application for cattle/pig/sheep and other animal ear marking with ear tag applicator

Request for a quoteXUFENG TOOL TECH GROUP LIMITED

China

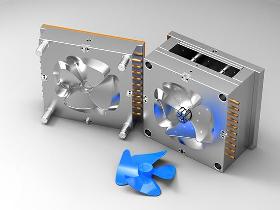

Rapid tooling Service We offer rapid tooling service, when parts demand quantity is hundreds to thousands,you will need to consdie this service and when your demand items are similar structure, types are many and demand quanity is not big then quick Turn Tooling. Rapid tooling for plastics and Die Casting of metal (Aluminum alloy or Zinc Alloy). Also we has stable surface treatment partner with different finishing like sand blasting, texture, painting, powder coating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have such project coming, you are welcomed to inquiry us freely . What Is Rapid tooling Rapid tooling is starting to be used to create molds for commercial operations,to simplify the mould structure for low cost & short lead-time. Rapid tooling provides a way to quickly provide molds to moulding the required products for low volume production demand. apid tooling material usually are Al7075 and...

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Rapid tooling for plastics and Die Casting of metal (Aluminum alloy or Zinc Alloy). Also we has stable surface treatment partner with different finishing like sand blasting, texture, painting, powder coating and so on, depending on our customers' requirements. We can make tool life to be 5k to 100ks or more. So if you have such project coming, you are welcomed to inquiry us freely . We manufacture our rapid toolings in material aluminium, P20, NAK80 and S136 tool steel, which can be run in a standard injection moulding machine to produce production quality parts in low-volumes. P20 prototype tooling for volumes up to 50,000+ shots. NAK80 or S136 prototype tooling for volumes up to 100,000+ shots. Prototype tooling in 5 to 28 calendar days. Tooling Lead-Time get short leadtime, Low Cost - reduced Cost from material ,MFG , Allowing real trials ,Allows functional test of parts on initial design stage, Many design faults are debugged before mass big production.

Request for a quoteResults for

Metals and alloys - Import exportNumber of results

15 ProductsCountries

Company type

Category

- Poultry farming - machinery and equipment (5)

- Cosmetics (3)

- Ceramics, industrial (1)

- Machine tools, metal machining - parts and accessories (1)

- Metalloids and compounds (1)

- Pipe and tube fittings - ferrous metal (1)

- Pipe and tube fittings - non-ferrous metal (1)

- Plastics moulding (1)

- SMALL METAL PARTS (1)