- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- servo motors

Results for

Servo motors - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The belt conveyor is adopted to supplement the bottle cap, the width of conveying can be adjusted according to the bottle caps, and it can fix the bottle caps of various sizes at the same time.Can add Aluminum-free foil eliminating device.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Multiple sets of servo motors are used to control all the emotion movements of the screw capping head.Use servo control the torque without damaging the caps.

Request for a quote

PJM MECHANICAL CO.,LTD

China

Voltage: 220V No.s of Poles: 8 No.s of encoder lines: 2500 PPR Rated Speed: 3000 RPM Rated torque: 1.27-2.4 N.M Work temperature: -10-55℃ Insulation Class: H CNC motor,Semi conduct motor,Military motor,Aerospace motor,Industrail automation motor.Application:Advertisement and engraving,wood engraving,digital control machine-tool,line cutter,ultrasonic welder,water cutter,optical fiber glass stretcher,gantry crane system,food processing,package printing

Request for a quote

PJM MECHANICAL CO.,LTD

China

Voltage: 220V No.s of Poles: 8 No.s of encoder lines: 2500 PPR Rated Speed: 3000 RPM Rated torque: 1.27-2.4 N.M Work temperature: -10-55℃ Insulation Class: H CNC motor,Semi conduct motor,Military motor,Aerospace motor,Industrail automation motor.Application:Advertisement and engraving,wood engraving,digital control machine-tool,line cutter,ultrasonic welder,water cutter,optical fiber glass stretcher,gantry crane system,food processing,package printing

Request for a quote

PJM MECHANICAL CO.,LTD

China

CNC motor,Semi conduct motor,Military motor,Aerospace motor,Industrail automation motor.Application:Advertisement and engraving,wood engraving,digital control machine-tool,line cutter,ultrasonic welder,water cutter,optical fiber glass stretcher,gantry crane system,food processing,package printing,paper board transport,textile print and dyeing,artificial chew simulator,blood tester,CAT scanner,DNA tester,pacemeter,robot

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The machine is adapted with advanced technology in the world. 1. Touch screen and PLC control 2.Low or missing label detect. 4. Synchronized speed selection 5. Servo motor drive for high accuracy and high speed 6. No bottle no labeling.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-TS two sides labeling machine is Mostly applicable for square, flat bottles, round containers for medicine, daily chemical, cosmetics, food cultural supplies, Electronic and etc. Advantages: 1. PLC CONTROL, Automatically check the length of labels 2. Equipped with warning device of insufficient labels, broken labels 3. No bottle, no labeling 4. No labels, no labeling 5.Servo motor control, stable labeling

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Easy to install, simple to operate and inexpensive to maintain For different flavor liquids only change the tubes high filling accuracy for small dosing liquid, from 1ml to 100ml is the best filling range if consider both the filling accuracy and speed Servo motor driven, easy adjustable filling volume,more working efficiently

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

One of the most significant advantages of an automatic piston filling machine is that it reduces labour costs and increases production speed. The machine can handle a high volume of products, which can help to reduce manufacturing costs in the long term. Furthermore, as the machine is fully automated, it minimises the risk of human error, which further increases production efficiency. Model Recommended: NP-VF 12 Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

it is widely application for the container pasting with two front and back labels, it is one type of self adhesive labeling machine, single and double side labeling is option, using for round container, square and flat container, also carton, boxes ,ect. It is automatic controlled by PLC easy operating. It can change specifications easily. It adopts servo motor, achieved closed loop control low malfunction rate. High efficiency. Double sides labeler we also call it as front and back labeling machine, for it is pasting two labels front and back. Advantages: 1. PLC CONTROL, Automatically check the length of labels 2. Equipped with warning device of insufficient labels, broken labels 3. No bottle, no labeling 4. No labels, no labeling 5.Servo motor control, stable labeling

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Automatic ionized air rinser/bottle cleaning machine is mainly used for clean the inside of the container , both for glass and plastic bottles, usging the pure filted ionized air and sunction the dust to ensure the containers are cleaning. This bottle air rinsing machine is a linear types, multy heads from 2 nozzles to 20 nozzles to meet the capacity demand, the diving nozzles driven by servo motor, and if choose the turn up types for cleaning, the turning arm will be also driven by a servo motor. The machine is universal for glass bottle and plastic bottle rinsing with air.. It blows inside of bottle with clean air and sucking the dust out of the bottle. The working principle is: when the bottle into the conveyor, the compressed air will be discharged high pressure air to clean the container, when blowing air meanwhile will suction the dust.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Servo motor driven the bottle clamper to turn up 180 degree, the turning speed is frequency converter control. The rinse spary head are specially designed for different types of containers, ensure 100% rinsing the inside of the bottles. Rinsing head will insert into the container for cleaning. The machine is frequency speed control, change bottles no need additional changeover parts. A high pressure water pump and a water recyling pump ensure the rinse pressure and recyling water in time under the spray rinse nozzles, it is water tank for recyling, meanwhile the whole machine is water proof, the water spray outside of the water tank also will be recyling into the water tank.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-HL is base on the NP-RL , it is high speed labeling machine, max labeling speed can reach 300bottles/min,It is suitable for a range of cartons in the range of label size The machine is adapt advanced technology in the world. Touch screen and PLC control Around 30 memory recipes for labeling parameters easy for change bottle size. Low or missing label detect. Synchronized speed selection Servo motor drive for high accuracy and high speed No bottle no labeling.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-RL Vertical round bottle labeling machine is a self adhesive labeling machine design for round bottle labeling with single label pasting. It is original technology from Italy, high speed labeling and stable.The whole machine frame is adapt 304 stainless steel,servo motor driven the labeling head, PLC control,frequency speed adjust.The labeler can equip with a date coder for printing date, LOT number, also bar code.The detection function is as an option, such as automatically rejection for missing label,automatic warning on missing label, automatic rejection for no date printing etc.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic detergent piston filling machine is a piece of equipment that is used to fill detergent products into bottles or containers. This machine operates by using a piston that pulls the product from a holding tank and then dispenses it into the containers. The process is automated, which means that the machine can fill a large number of containers quickly and efficiently. Feature: Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L Hopper: automatic liquid feeding system Container: suitable for 0.5-2L Plastic bottles Voltage: 220VAC 50/60Hz Power: 2000W Drop-proof filling nozzles: adapting vacuum sucking nozzles. Touch Screen Language: English and Chinese

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

It is PLC control the flowmeter open and shut off, servo motor driven the filling nozzles moving up and down. Capacity: The capacity of an automatic flowmeter filling machine can vary depending on the model, but typically ranges from 500 ml to 5 liters. Material: Most flowmeter filling machines are made from stainless steel or other food-grade materials to ensure the quality and safety of the product being filled. Speed: The speed of the filling process can be adjusted depending on the viscosity of the liquid and the desired fill volume. Typically, these machines can fill between 30 and 60 bottles per minute. Accuracy: Flowmeter filling machines are known for their high level of accuracy in measuring the volume of the liquid being filled. They can achieve accuracy levels of +/- 0.5%. Operation: The operation of an automatic flowmeter filling machine is typically

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-OF Automatic Multy Head Overflow Liquid Filling Machine works by feeding the liquid through a specific pump or a top storage tank. Simultaneously, once the feeding is completed, a portion of the material returns to the liquid overflow tank via the overflow port to guarantee the filled bottle in same level. The depth of the overflow port in the container neck determines the container’s filling level, which is easily adjustable. The number of filling heads can be increased to meet production needs. It’s ideal for filling low-viscosity, high foamy liquid in the chemical, food, pharmaceutical, and other sectors. Vacuum overflow filler system is for optional,filling nozzles moving up and down by servo motor driving, specially designed overflow filling nozzles.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

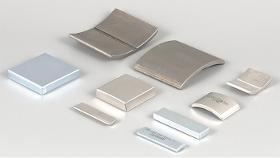

NINGBO ZHAOBAO MAGNET CO., LTD.

China

Application: Industrial Automation Motor Shape: Block, Cylinder, Disk, Rings, Segment, Tile, Arc, Sector, Special Shapes. Materials: Sintered NdFeB Magnet/Neodymium Magnet Grade: N30H~N50H,N30SH~N48SH, N28UH~N48UH, N28EH~N40EH Coating: NI, NiCuNi, ZN, Epoxy, etc. Density ≥7.55g/cm3 Size: As per customers’ design Quality Management System: IATF 16949:2016 / ISO9001:2015 Occupational Health and Safety: ISO 45001:2018 Environmental Management: ISO 14001:2015 HS Code: 8505111000 /8505119000 Manufacturer: Ningbo Zhaobao Magnet Co., Ltd. Brand: ZHAOBAO MAGNET

Request for a quote

PJM MECHANICAL CO.,LTD

China

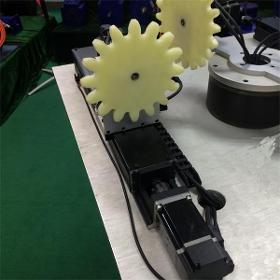

A gearbox is a mechanical motion device of transferring energy from one device to another and is used to change the speed (RPM) or the output torque of a motor.It is also well-knowed as gear reducer,speed reducers or gearhead. The gearbox is one of the most important power transmission parts in motion control systems.The power transmission industry need a gearbox to offer loads while the motion control or servo industry may need a gearbox to handle dynamic motion. For robots automation control

Request for a quote

PJM MECHANICAL CO.,LTD

China

We offer planetary gearboxes with varied backlash degrees such as normal (only needs torque output), precision (max backlash 13 or 15 arcmins), high precision (max backlash 8 or 9 arcmins), and super-high precision (max backlash 4 or 5 arcmins).

Request for a quote

PJM MECHANICAL CO.,LTD

China

Low Backlash: Backlash is under 3 arcmin.Backlash for 2 stage speed reduction is within 5 arcmin High Efficiency:Efficiency for 1 stage model exceeds 95%,2 stage model exceeds 92% Size:PLF060/PLF080/PLF090/PLF120/PLF160 Output Rated Torque Range:From 9Nm to 500Nm Adapter-bushing connection,can be attached to any motor No Grease Leakage and Maintenance-free Planetary Gearbox Application:Aerospace,military industry,Medical health,electronic information industry,Industrial robots,production automation,CNC machine tool manufacturing industry,Auto industry,textile,printing,food,metallurgical,environmental protection engineering,warehouse logistics industry

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Powder – flour – Spice – corn flour – Sugar powder – Soda powder – Sweet powder Features: * Low-cost high gain, high speed, and efficiency. * Famous brand PLC control system, large touch screen, convenient to operate; * Film drawing down system and horizontal sealing controlled by servo motor; * Minimize the loss with complete automatic warn protection function; * It can complete feeding, measuring, filling, sealing, date printing, charging (exhausting), counting, and finished product delivery when it equips with feeding and measuring equipment. * the way of bag making: the machine can make pillow-type bags and standing bags according to customer’s requirements.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

This machine is widely used for packing sauce, honey, water, oil, month wash, or some liquid.Automatically measuring volume, making bags, filling, sealing, cutting, printing the lot number and cutting easy tearing notches,finished product conveying. Features: (1).Famous brand PLC control system,large touch screen,convenient to operate; (2).Film drawing down system by famous bland servo motor. (3).Advanced design,high precision and fast speed; (4).Various alarm system to reduce waste; (5).Photoelectric tracking system for precise bag length and position of film.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Irregular shaped sachet packing machines automatically finish the processes of pouch forming, filling, sealing, cutting, and date printing. The best feature is the pouch shape is irregular like round, strip, polygonal, bottle-shaped and so on. This machine can be used to make different shapes good-looking pouches according to customer requirements. And it is suitable for fruit juice, honey, ketchup, cream, shampoo, cosmetics, etc. Equipment Feature: 1. Smart PLC controller and display with high reliability, high stability, and extremely low error rate. 2. Servo motor control bag system with high precision bag making. 3. Full 304 stainless steel feeding hopper, more healthy and easy clean. 4. Less abrasion, high efficiency, and long service life. 5. Choose the appropriate feeding device according to the material, special material special pump, and prevent leakage.

Results for

Servo motors - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Bottling and filling - machinery and equipment (12)

- Packing and packaging - machinery and equipment (3)

- Driveshafts and micro-motors - electric (2)

- Welding, electric - equipment and supplies (1)

- Chemical industry - machinery and equipment (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Electric motors - dC (1)

- Labelling machines (1)

- Laser printing (1)

- Magnets (1)

- Textile finishing - machinery and equipment (1)