- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting tools

Results for

Cutting tools - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

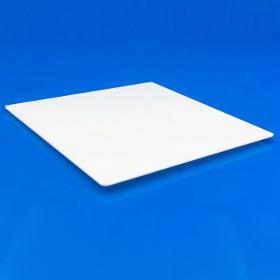

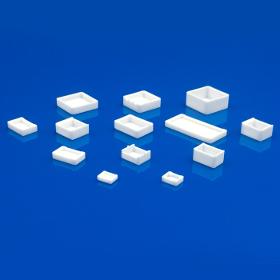

Zirconia ceramic disc plates are characterized by high toughness, high bending strength, high hardness and high wear resistance.Zirconia ceramics have a dimensional hardness of 11.5GPa, a density of 6.0g/cm3 and a compressive strength of 2100MPa. Zirconia ceramics are widely used as ductile ceramics with fracture toughness up to 8.0 mpAM1/2. Advantages: smooth surface (easy to clean), good toughness, impact resistance, high hardness, wear resistance, low thermal conductivity (heat insulation), generally no insulation and high temperature resistance Applications: machinery, optical fiber, cutting tools, medical, food, chemical, aerospace Ceramic material composition: - - 95%--99.99% Alumina (Al2O3) - - Silicon Carbide · Silicon Nitride - - TTZ: Magnesia partially stabilized Zirconia (ZrO2) - - YTZP: Yttria partially stabilized Zirconia (ZrO2) - - ZDY: Yttria fully stabilized Zirconia (ZrO2)

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride ceramid textile guides shoes is high wear resisting than zirconia and alumina, it will be more widely use in the textile industry in future. Silicon nitride has better high temperature capabilities than most metals combining retention of high strength and creep resistance with oxidation resistance. In addition, its low thermal expansion coefficient gives good thermal shock resistance compared with most ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity Typical Silicon Nitride Uses: .Rotating bearing balls and rollers .Cutting tools .Engine moving parts - valves, turbocharger rotors .Engine wear parts - cam followers, tappet shims .Turbine blades, vanes, buckets .Metal tube forming rolls and dies .Precision shafts and axles in high wear environments .Weld positioners

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: Surface grinders CNC milling machines Jig grinders Centerless grinders CNC lathes ID grinders

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic is a kind of ceramic material with a-al2o3 as the main crystal phase, because of its own high melting point, high hardness, heat resistance, corrosion resistance, and electrical insulation characteristics, it can be used in more stringent conditions. Alumina ceramics, with low price and mature production process, is one of the largest and most widely used ceramic materials, mainly used in the field of cutting tools, wear-resistant parts, and bioceramics. In addition, it is also widely used in energy, aerospace, chemical electronics, and other aspects. Especially 95% alumina and 99% aluminas, whether in structural ceramics or electronic ceramics are one of the most widely used ceramic materials. .Purity:92%,96% and 99.7% .Good mechanical strength .Excellent electrical insulation .High-frequency loss .Good thermal conductivity .Heat,wear and corrosion resistance Alumina is the best-known advanced ceramic material, is widely used in automotive,petro-chemical

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: * Surface grinders * CNC milling machines * Jig grinders * Centerless grinders * CNC lathes * ID grinders

Request for a quote

XUFENG TOOL TECH GROUP LIMITED

China

Xu Feng offer CNC Milling part including 3- axies ,4-axies and 5-axies ,so no matter parts with simple or complex structure ,we can make it as per client's part design or sample,cnc milling torance we can reach 0.05mm,part material we milled usually is Aluminum,brass ,copper ,brozen,stainless steel and plastic (PP,PC,ABS,POM,PVC,PA66+30%GF) CNC milling is used to apply a machined surface finish on plastic or metal, or for creating complex 3D shapes. CNC milling is one of the most flexible machining methods and able to make a wide range of custom parts. CNC milling is a cutting process in which material is removed from a block metal or plastic by a rotating tool. The cutting tool (called a “mill”) is moved in all three dimensions to cut a desired shape from stock.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cutting tools - Import exportNumber of results

6 ProductsCountries

Company type