- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- combined machines

Results for

Combined machines - Import export

MING XIAO MANUFACTURING CO., LTD

China

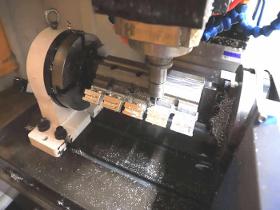

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours. sales@mxmparts.com WhatsApp +86 13780014913

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours. sales@mxmparts.com WhatsApp +86 13780014913

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours. sales@mxmparts.com WhatsApp +86 13780014913

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Ming Xiao Mfg custom CNC milled parts for world clients, equipped 3,4,5 Axis CNC Machining Center several sets, can provide precision CNC milling services with low prices and high quality. High Precision Production. Ming Xiao Mfg custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs Extensive Material Option. Wide variety of certified materials (over 50 metal and plastic materials) and surface finishes available The common used materials such as Brass,Copper,Aluminum,Steel,Stainless Steel & Plastics. Rapid prototyping. Get prototypes quickly, optimize the entire high-speed milling workflow with advanced milling machines and full equipped CNC milling factory. We also provide precision CNC Turning + Milling Combination Machining Service, Send your inquiry or drawing fast to get an rapid quote in 48 hours.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg offers the highest-quality precision machined mill-turned parts that are engineered to fit your specific application needs. Our CNC mill-turn machining utilizes the latest technology and the highest level of craftsmanship to create parts with the perfect fit and accuracy for any project. What is Mill-Turn Machining? Mill-turn machining is a type of precision CNC machining that uses advanced machines to create a variety of complex parts. The machines used for mill-turn machining combine both milling and turning operations into one setup. Capable of performing multiple simultaneous operations such as drilling, milling, and tapping, mill-turn machining is ideal for parts that require complicated geometries. We Specialize In: Multi-Axis Machining Milling Turning Thread Milling Drilling Tapping Slotting Chamfering Common Applications for Mill-Turned Parts is automotive, medical, aerospace, and food & beverage, etc. Contact us: sales@mxmparts.com

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1. Rotary packing machine combinate with the multi-heads weighing machine, Z-type conveyor, platform, accurate measurement, fast speed, low defective rate, low noise. 2. Eight stations rotary design to automatic control a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5. The lifting system is suitable for a wide range of industries, like food fodder, chemical, and so on granule material packing. 6. Strictly follow the mechanical standards to production, ensure the quality, reduce late wear, and reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary pouch bagging vacuum packaging machine combine with different fillers,such as weighing machine,liquid pump and auger/agitator fillers, accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design to automatic control a series of processes from bag-giving,coding,bag-opening,filling,vacuuming,sealing,and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials.Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids. 3.Adopt Siemens PLC control system, be easily performed operation and maintenance. 4.Filling machine rotates intermittently to fill the product easily and vacuum machine rotates continuously to enable smooth running, it means high performance and high durability.All grippers width of filling machine can be adjusted at once by a motor but all grippers in the vacuum chambers are no need to adjust.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with liquid pump cylinder measurement,accurate measurement, fast speed, low defective rate, low noise,add the reflow system can avoid liquid material leakage. 2. Eight stations rotary design to automatic control of a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5.Modular heating, more accurate temperature control, heating failure can alarm prompt. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with servo auger/agitator feeder system,30-50L fillers,and lifting conveyor,accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design ,compact and reasonable arranged in the smallest amount of space,to automatic control of a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.Adopt Siemens PLC control system, touch screen can set variety of languages,simple operation, and easy maintenance. 4.The machine use premade pouch,you have more choice for the bag type and excellent appearance .Sealing good, the finished product looks high-end. 5.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 6.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

Results for

Combined machines - Import exportNumber of results

11 ProductsCountries

Company type