- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- advanced materials

Results for

Advanced materials - Import export

PEEKCHINA CO., LTD.

China

PEEK material performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK ARKPEEK-GF30: 30% glass fiber + 70% PEEK ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK Ceramic Composites Elevate your applications with our PEEK ceramic composite. This advanced material combines the exceptional properties of PEEK with the added strength and durability of ceramic. Experience enhanced mechanical performance and wear resistance, making it the perfect choice for demanding industrial solutions. Choose PEEK filled with ceramic for precision and resilience in extreme conditions.

Request for a quote

PEEKCHINA CO., LTD.

China

OVERVIEW of PEEK Insulating Film Experience unmatched insulation performance with Semi-crystalline PEEK Film. Engineered to excel in electrical and thermal insulation systems, this advanced material ensures reliability and efficiency in even the most demanding environments. Elevate your insulation standards and trust in the insulating prowess of Semi-crystalline PEEK Film for your critical applications.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK workpieces are the ultimate solution for those seeking unrivaled durability and reliability in their manufacturing processes. These advanced materials offer exceptional mechanical properties, including high tensile strength, excellent creep resistance, and low coefficient of friction. PEEK workpieces are also known for their dimensional stability, resistance to chemicals, and high temperatures, making them ideal for demanding applications. With their versatility and performance combined, PEEK workpieces are setting a new standard in the industry, offering enhanced efficiency and productivity to manufacturers worldwide.

Request for a quote

PEEKCHINA CO., LTD.

China

The Wear-Resistant PEEK Composites Arm Plain Bearing is an exceptional choice for heavy-duty applications that demand reliable and long-lasting performance. Engineered with superior wear resistance, this bearing can withstand the harshest operating conditions, ensuring extended service life and reducing the need for frequent replacements. Its robust construction and advanced materials make it highly resistant to abrasion, impact, and fatigue, enabling it to handle high loads and harsh environments with ease. By choosing the Wear-Resistant PEEK Composites Arm Plain Bearing, you can optimize your equipment's reliability, minimize downtime, and achieve substantial cost savings in maintenance and replacement.

Request for a quote

PEEKCHINA CO., LTD.

China

CF/PEEK components, made from a combination of carbon fiber and polyether ether ketone, offer unparalleled wear-resistance and durability. These advanced composite materials are designed for demanding applications where high performance and longevity are essential. With excellent mechanical properties, thermal stability, and resistance to chemicals, CF/PEEK components are ideal for industries such as aerospace, automotive, and manufacturing.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, from 10kg- 15 tons 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

PEEKCHINA CO., LTD.

China

ARK-BioPEEK offer ASTM F2026-17 compliant polyetheretherketone (PEEK) polymers designed specifically for surgical implant applications. Our advanced PEEK materials provide exceptional biocompatibility, mechanical strength, and thermal stability, meeting the stringent requirements of surgical implantation. Trust ARKPEEK and ARK-BioPEEK for high-quality PEEK solutions that ensure reliable and long-lasting performance in surgical procedures. ARK-BioPEEK introduce a range of cutting-edge polyetheretherketone (PEEK) polymers meticulously engineered for surgical implant applications. Our PEEK materials adhere to the rigorous specifications outlined in ASTM F2026-17, ensuring compliance with industry standards and delivering uncompromising quality.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, custom drawing 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Gravity Casting Aluminum for Light Housing Clutch Body 1, Die casting, gravity casting, sand castings 2, Materials: Aluminum alloy, zinc alloy, bronze etc. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, Die casting, gravity casting, sand castings 2, Materials: Aluminum alloy, zinc alloy, bronze etc. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Aluminum Die Castings ADC12 A356 for engine 1, Die Casting, Gravity Casting, Sand Casting 2, Materials: Aluminum alloy, zinc alloy, bronze. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, custom drawing 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, Lose Wax Process(soluble glass): wax injection, wax welding, dipping, sand-coating, shell-making, dewaxing, cleaning, pouring, cutting, reshaping, machining. 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, Lose Wax Process(soluble glass): wax injection, wax welding, dipping, sand-coating, shell-making, dewaxing, cleaning, pouring, cutting, reshaping, machining. 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

PEEKCHINA CO., LTD.

China

Our PEEK rotor seals are precision-engineered to deliver superior chemical resistance and mechanical strength. Designed for use in demanding applications like HPLC systems and other analytical instruments, these seals provide excellent durability and leak-free performance under high-pressure conditions. Their unique design ensures smooth operation, minimal maintenance, and extended equipment life, even in aggressive chemical environments. The combination of PEEK's high-performance material and advanced engineering makes them a reliable choice for critical laboratory applications.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, custom drawings 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

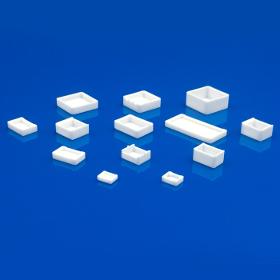

Alumina ceramic (Aluminum Oxide or Al2O3) is an excellent electrical insulator and one of the most widely used advanced ceramic materials. In addition, it is extremely resistant to wear and corrosion and is an industrial ceramic that can only be formed by diamond grinding. The melting point is very high at 2,072°C, and it is very hard. Alumina components can be widely used in electronics, pump components and automotive sensors.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

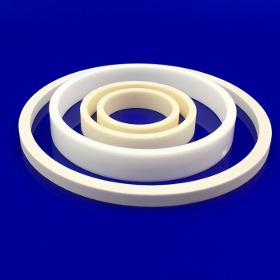

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: Surface grinders CNC milling machines Jig grinders Centerless grinders CNC lathes ID grinders

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: * Surface grinders * CNC milling machines * Jig grinders * Centerless grinders * CNC lathes * ID grinders

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic is a kind of ceramic material with a-al2o3 as the main crystal phase, because of its own high melting point, high hardness, heat resistance, corrosion resistance, and electrical insulation characteristics, it can be used in more stringent conditions. Alumina ceramics, with low price and mature production process, is one of the largest and most widely used ceramic materials, mainly used in the field of cutting tools, wear-resistant parts, and bioceramics. In addition, it is also widely used in energy, aerospace, chemical electronics, and other aspects. Especially 95% alumina and 99% aluminas, whether in structural ceramics or electronic ceramics are one of the most widely used ceramic materials. .Purity:92%,96% and 99.7% .Good mechanical strength .Excellent electrical insulation .High-frequency loss .Good thermal conductivity .Heat,wear and corrosion resistance Alumina is the best-known advanced ceramic material, is widely used in automotive,petro-chemical

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ball Mill /Beads / Grinding Media is made of good material and used advanced technology, which is suitable for any kinds of mills such as sand mill, attrition-mill, vibratory mill, ball mill and so on. It is used to grind and disperse the material of painting, dye,ink, titanium, electronic battery material, rare-earth material, nonmetal ore, calcium, pesticide, food stuff and medicine etc..Because of its high density, toughness and hardness, zirconium grinding media’s efficiency is much better than traditional ones.The high wear-resistant zirconium grinding media can not only prevent materials from being contaminated, but also prevent chemical erosion that affects its working life Sizes Ømm of the Zirconia ball mill grinding media : - 0.2-3mm,5mm,10mm,15mm,20mm Usage of the Zirconia ball mill grinding media: - Ø0.5-3mm Grinding ball use in sand mill - Ø5-20mm Grinding ball use in mix mill and ball mill - OverØ20mm Grinding ball use in ball mill

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as Aluminum Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications. Once fired and sintered, it can only be machined using diamond-grinding methods. It features high hardness and wear resistance, low erosion levels, high temperature resistance, corrosion resistance, and bioinertness.Additionally, it can be highly polished, making it useful for a wide range of applications. Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5. High mechanical strength 6. High compressive strength 7. High hardness

Request for a quoteResults for

Advanced materials - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Ceramics, industrial (6)

- Ceramics, refractory (4)

- Plastic products for engineering (4)

- Foundries, aluminium (2)

- Gears (2)

- Seals (1)

- Casting of special and high-grade steels (1)

- Casting, steel (1)

- Disposable medical and surgical articles (1)

- Mechanical transmission - components (1)

- Plastic material processing (1)

- Plastic products for the electronics industry (1)

- Reducing gears, hydraulic (1)

- Trailers, industrial (1)