- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining of industrial ceramics

Results for

Machining of industrial ceramics - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Valve Core For Coca-Cola Machine Alumina ceramic valve core for a Coca-Cola machine refers to a component used in the dispensing system of the machine that controls the flow of the beverage. The valve core is a small, cylindrical piece made of ceramic material that is inserted into the machine's dispensing mechanism. The use of ceramic valve cores in Coca-Cola machines is preferred over other materials such as plastic or metal due to their durability and resistance to corrosion. Ceramics is also an excellent material for maintaining the flavor of the beverage as it is non-reactive, meaning it does not absorb any flavors or odors from the beverage. The valve core is responsible for regulating the flow of the beverage through the machine's dispensing system, controlling the amount of liquid dispensed per use. It is an essential component of the machine and should be regularly maintained to ensure optimal performance.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

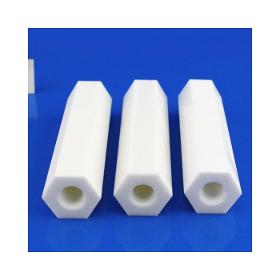

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Electrical Insulation Macor Rod: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Rod for Heating Element Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Rod Applications 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic Square Ring: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Ceramic Square Ring Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Square Ring Applications: 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: Surface grinders CNC milling machines Jig grinders Centerless grinders CNC lathes ID grinders

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quoteResults for

Machining of industrial ceramics - Import exportNumber of results

8 ProductsCountries

Company type