- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- insulators

Results for

Insulators - Import export

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK (Polyether Ether Ketone) heat shrink tubing is revolutionizing the medical device industry with its exceptional properties and reliable performance. Known for its high-temperature resistance, chemical resistance, and mechanical strength, PEEK heat shrink tubing provides unparalleled protection and insulation for sensitive medical equipment. Whether it's ensuring the durability of surgical instruments or protecting the intricate wiring of diagnostic devices, PEEK tubing is the ideal choice for enhancing the safety, efficiency, and longevity of medical devices. Its low flammability and excellent electrical insulation further contribute to its suitability in critical healthcare applications, making it an essential component for medical device manufacturers seeking high-performance solutions.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK material performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK ARKPEEK-GF30: 30% glass fiber + 70% PEEK ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite

Request for a quote

PEEKCHINA CO., LTD.

China

This high-performance material boasts exceptional mechanical strength, chemical resistance, and thermal stability, making it the ideal choice for precision engineering and complex component manufacturing. Lightweight yet durable, our PEEK sheet excels in high-temperature environments and offers excellent electrical insulation properties.

Request for a quote

NEWSUN PV TECHNOLOGY CO.,LTD

China

4in1 Piercing connector for model number IPC4116120: IP67 waterproof; UV-resistant; Anti-corrosive; Low voltage; Constant torque nut; Copper tin plated conductor; Inner waterproof silica gel.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Feature: Electrical Insulation and Extremely High Voltage; Application: Extrusion & Injection Moulding; Customized: Yes and contact for material solution.

Request for a quote

PEEKCHINA CO., LTD.

China

Form: Granule; Feature: Heat Insulation and Low Thermal Conductivity; Application: Extrusion & Injection Moulding; Customized: Yes and contact for material solution.

Request for a quote

PEEKCHINA CO., LTD.

China

OVERVIEW of PEEK Insulating Film Experience unmatched insulation performance with Semi-crystalline PEEK Film. Engineered to excel in electrical and thermal insulation systems, this advanced material ensures reliability and efficiency in even the most demanding environments. Elevate your insulation standards and trust in the insulating prowess of Semi-crystalline PEEK Film for your critical applications.

Request for a quote

PEEKCHINA CO., LTD.

China

PEEK E-motors Insulation In response to the evolving landscape of higher voltage platforms reaching up to 800V and the integration of advanced SiC and GaN switching technologies, the demands placed on e-motor insulation have never been more exacting. Introducing our latest innovation: ARKPEEK polymer grades. Specifically engineered to address the stringent requirements of extrusion wire manufacturing processes, these advanced polymers deliver an unparalleled combination of exceptional electrical properties, robust mechanical strength, high-temperature resilience, and chemical resistance.

Request for a quote

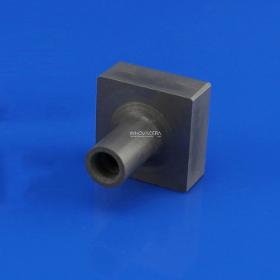

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1. Good thermal shock resistance 2. Creep resistance 3. Low density 4. High fracture toughness 5. High hardness and wear resistance 6. Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3) 96% ceramic plates are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Si3N4 Silicon Nitride Tube Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Electrical Insulation Macor Rod: Machinable Glass Ceramic has a continuous use temperature of 800oC and a peak temperature of 1000oC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed,ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant. Macor Rod for Heating Element Features: 1.High Dielectric Strength, Excellent Insulation 2.Good Machinability, Machinable With Ordinary Metal Tools And Fast Turnaround 3.High Precision, Hold High Tolerance 4.Excellent Acid And Alkali Resistance 5.No Outgasing And Zero Porosity 6.Withstand High Temperature Up To 800℃ Machinable Glass Ceramic Rod Applications 1.high strength and high tenacity product, magnetic material, piezoelectric ceramic, dielectric ceramics

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

In a development that could have a significant impact on the electronics industry, the latest ceramic metallized insulators are making strides in enhancing semiconductor packaging and related applications. These insulators offer a range of practical benefits that can improve the performance and durability of electronic components. Let’s take a closer look at what sets them apart: Key Features of Ceramic Metallized Insulators: 1. Stability and Strength: The ceramic material employed in these insulators boasts an even texture, ensuring every batch maintains stable quality and flexural strength. This consistency in material quality is pivotal for the reliability of electronic components. 2.Dense and Weldable Metal Layer: The metal layers in these insulators are densely applied, providing a smooth and even surface. This not only enhances their appearance but also makes them easy to work with, particularly in manufacturing processes.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride heat shields and magnetic rings are mainly used to protect high voltage electrodes and are widely used in the photovoltaic industry.Heat shields and magnetic rings, as well as ceramic rings, are collectively referred to as electrode shields.Silicon nitride electrode protection cover mainly uses silicon nitride insulation, heat resistance and corrosion resistance.Compared with the protective cover of quartz and alumina which is still in use today, the service life of the silicon nitride electrode shield is more than 10 times, and it will not be electrically broken down during use, and will not be heated, nor will it be heated. Will be eroded away. Due to its own stability, in the use of photovoltaic reduction furnaces, the collapse rate of non-human factors is greatly reduced. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses.It processes good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. Wire bushing, also known as insulating bushing, is a new type of composite pipe with insulating materials. It is made of resin matrix and other reinforced materials. It is used to wear wires and protect wires, so it is called wire bushing. The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. It is easier and more convenient to move and transport than metal steel pipe and cement pipe. The construction and installation are simple and convenient, which saves both trouble and labor. Strong corrosion resistance, insulation, non-magnetic, acid and alkali resistance, flame retardant, antistatic.

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. Wire bushing, also known as insulating bushing, is a new type of composite pipe with insulating materials. It is made of resin matrix and other reinforced materials. It is used to wear wires and protect wires, so it is called wire bushing. The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. It is easier and more convenient to move and transport than metal steel pipe and cement pipe. The construction and installation are simple and convenient, which saves both trouble and labor. Strong corrosion resistance, insulation, non-magnetic, acid and alkali resistance, flame retardant, antistatic.

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. Wire bushing, also known as insulating bushing, is a new type of composite pipe with insulating materials. It is made of resin matrix and other reinforced materials. It is used to wear wires and protect wires, so it is called wire bushing. The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. It is easier and more convenient to move and transport than metal steel pipe and cement pipe. The construction and installation are simple and convenient, which saves both trouble and labor. Strong corrosion resistance, insulation, non-magnetic, acid and alkali resistance, flame retardant, antistatic.

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. Wire bushing, also known as insulating bushing, is a new type of composite pipe with insulating materials. It is made of resin matrix and other reinforced materials. It is used to wear wires and protect wires, so it is called wire bushing. The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. It is easier and more convenient to move and transport than metal steel pipe and cement pipe. The construction and installation are simple and convenient, which saves both trouble and labor. Strong corrosion resistance, insulation, non-magnetic, acid and alkali resistance, flame retardant, antistatic.

Request for a quote

SHANGHAI GAOHE IMP. & EXP. CO., LTD.

China

The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. Wire bushing, also known as insulating bushing, is a new type of composite pipe with insulating materials. It is made of resin matrix and other reinforced materials. It is used to wear wires and protect wires, so it is called wire bushing. The insulating sleeve has the characteristics of strong pressure resistance, light weight, smooth inner wall and small friction coefficient, so it is easy to wear the wire without damaging the wire. It is easier and more convenient to move and transport than metal steel pipe and cement pipe. The construction and installation are simple and convenient, which saves both trouble and labor. Strong corrosion resistance, insulation, non-magnetic, acid and alkali resistance, flame retardant, antistatic.

Request for a quoteResults for

Insulators - Import exportNumber of results

24 ProductsCountries

Company type